Large-span prestressed concrete assembly type frame connecting joint and construction method

A technology for connecting nodes and concrete, which is applied in the direction of climate change adaptation, protective buildings/shelters, building types, etc., and can solve the constraints of popularization and application, the inability to fully exert the effective control of prestressed tendons, and damage to self-resetting performance, etc. problems, to achieve the effect of improving compressive strength and ultimate compressive strain, good self-resetting ability, and reducing plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

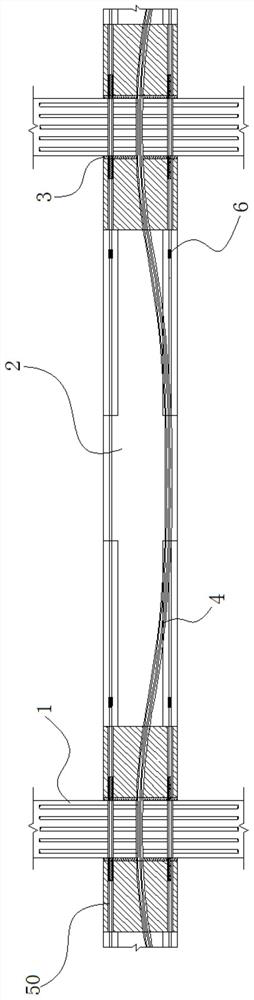

[0035] This embodiment discloses a large-span prestressed concrete assembled frame connection node, including prefabricated columns 1, prefabricated beams 2, prestressed tendons 4, beam mid-span reinforcements 5 and node connection area reinforcements 50.

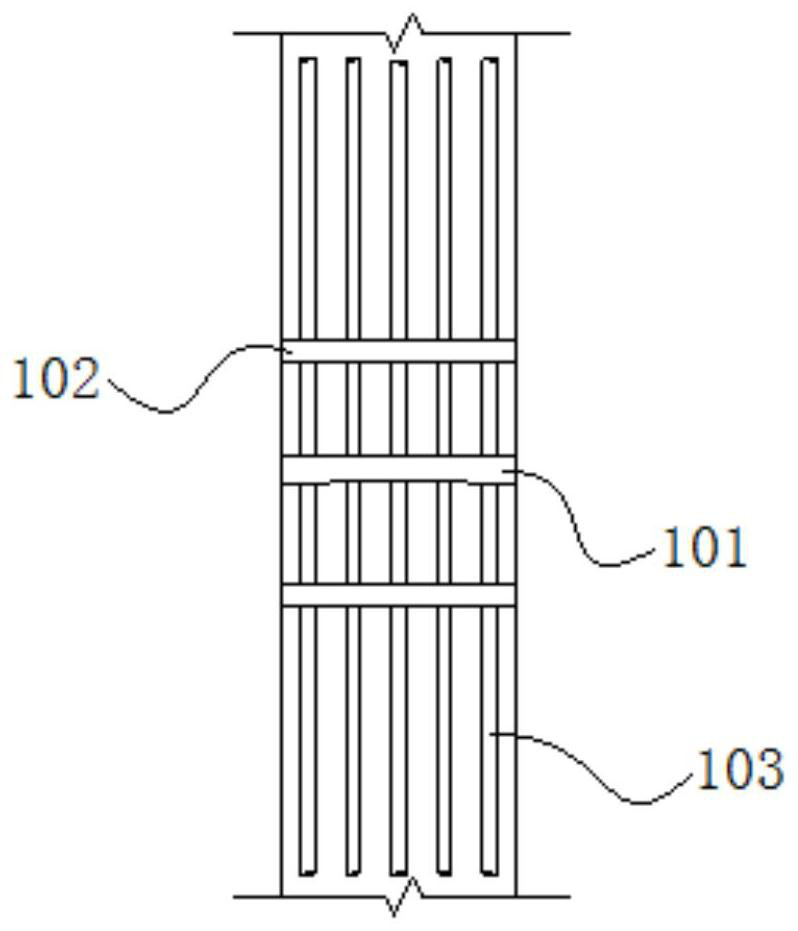

[0036] The prefabricated column 1 is a precast concrete column. The prefabricated column 1 is reserved with a prestressed tendon channel I101 in the node area. The prefabricated column 1 is pre-embedded with upper and lower reinforcement tunnels I102 in the joint area. The upper and lower reinforcement tunnels I102 are respectively arranged on the upper and lower sides of the prestressing tendon tunnel I101.

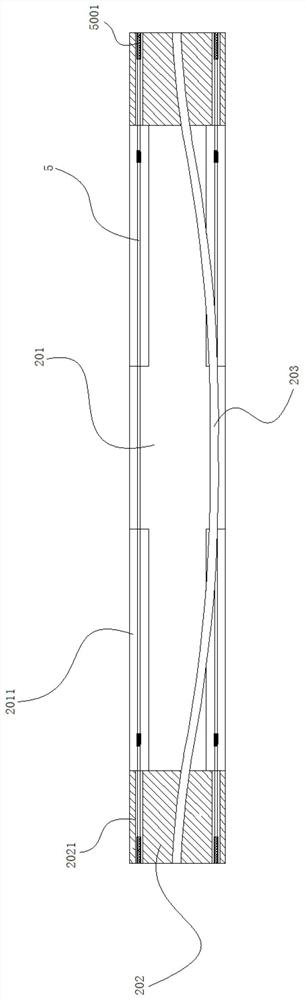

[0037] The prefabricated beam 2 is a single-span prestressed concrete beam. The beam body of the prefabricated beam 2 is arranged with a prestressed tendon channel II 203 . The prefabricated beam 2 includes a beam body 201 and beam end joints 202 arranged at two ends of the beam body 201 . The beam main body 201 i...

Embodiment 2

[0043] see Figure 1 ~ Figure 3 , The main structure of this embodiment is the same as that of Embodiment 1, wherein, a column longitudinal reinforcement 103 is also arranged in the column body of the prefabricated column 1 . The steel bar 50 in the node connection area is connected with the steel bar 5 in the middle span of the corresponding beam using a steel bar sleeve 6 .

Embodiment 3

[0045] The main structure of this embodiment is the same as that of Embodiment 1, wherein the steel bar 50 in the node connection area and the steel bar 5 in the corresponding beam span are connected by welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com