Tractor power high gear, power reversing and crawling gear combined transmission

A technology of combined transmission and reversing device, which is applied in the field of tractors, can solve the problems that the hitch is not as convenient as the meshing sleeve and synchronizer, the processing and assembly is inconvenient, and the oil churning loss is large, so as to facilitate processing and lubricating oil entry, and is beneficial Heat balance, small shear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

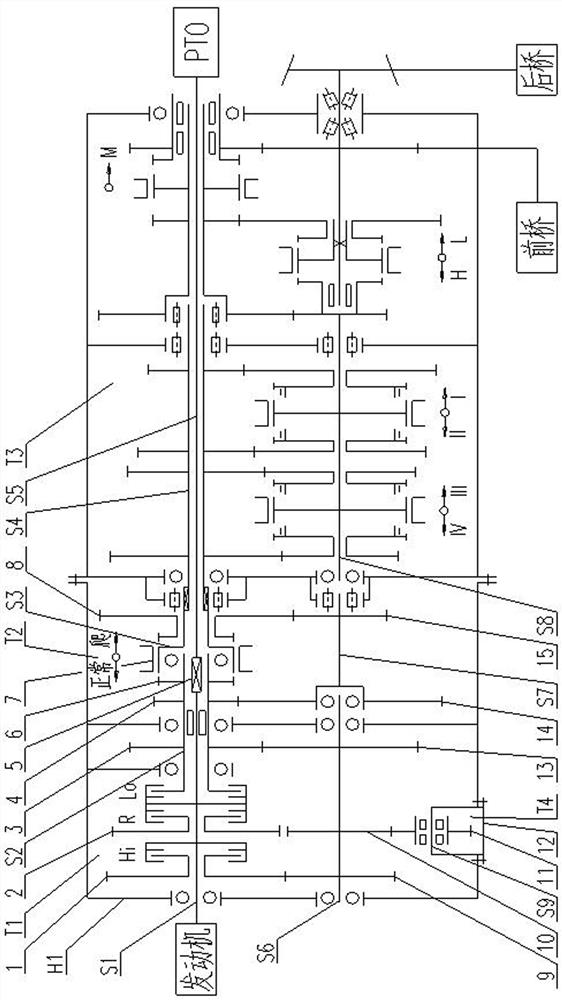

[0020] as attached figure 1 As shown in the figure, the tractor power high gear, power reversing and crawling gear combined transmission device is composed of two parts, the power shifting reversing device T1 and the crawling gear device T2, which are arranged in the box. One end of the power shifting reversing device T1 is connected to the The engine is connected, the other end is connected to one end of the creeper gear device T2, the other end of the creeper gear device T2 is connected to the gearbox T3, and the input of the power shift reversing device T1 is connected to the power output shaft S5.

[0021] The power shift reversing device T1 is installed with a high gear reversing input shaft S1, a gear reversing output shaft S2, a high gear reversing driven shaft S6 and an idler gear assembly T4, and a crawling gear device T2 is installed with a creeping input The shaft S7 and the creeping output shaft S3; the high-speed reversing input shaft S1, the shifting reversing ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com