Calibration method for dynamic test of detecting wheel

A technology of dynamic testing and calibration methods, which is applied to measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as the inability to judge the state of the probe wheel, and the inability to use calibration and calibration methods to achieve fast flaw detection operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0025] This embodiment provides a calibration method for dynamic testing of probe wheels, which includes the following steps:

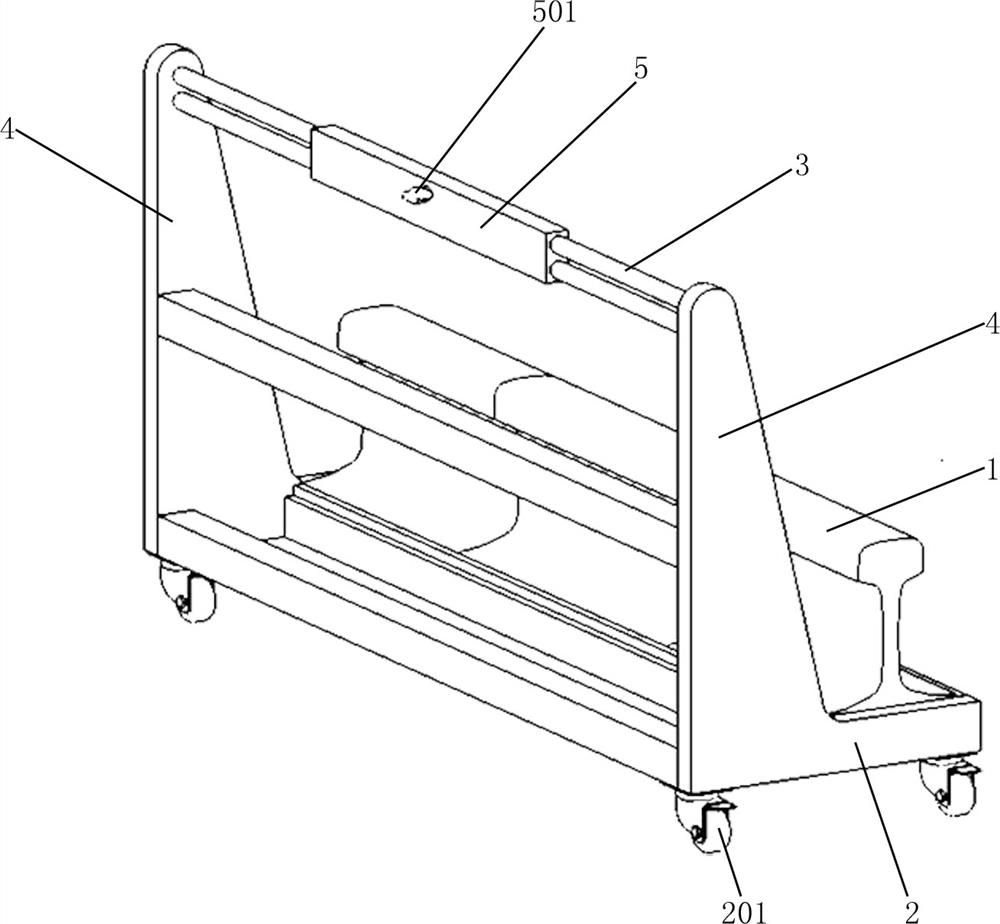

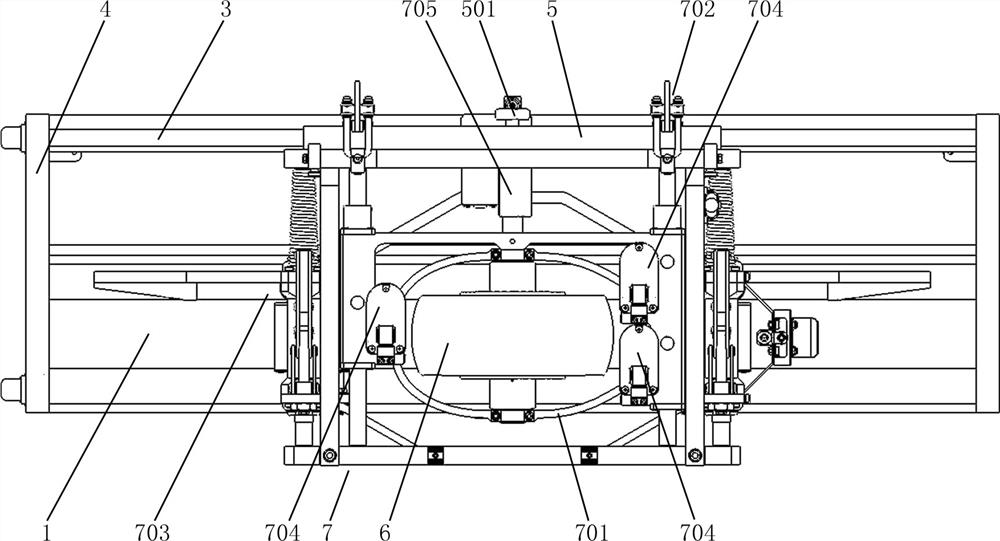

[0026] Step 1: Fix the test block 1 on the test block frame, and then delineate the center line of the test block 1 along its axial direction on the upper surface of the test block 1;

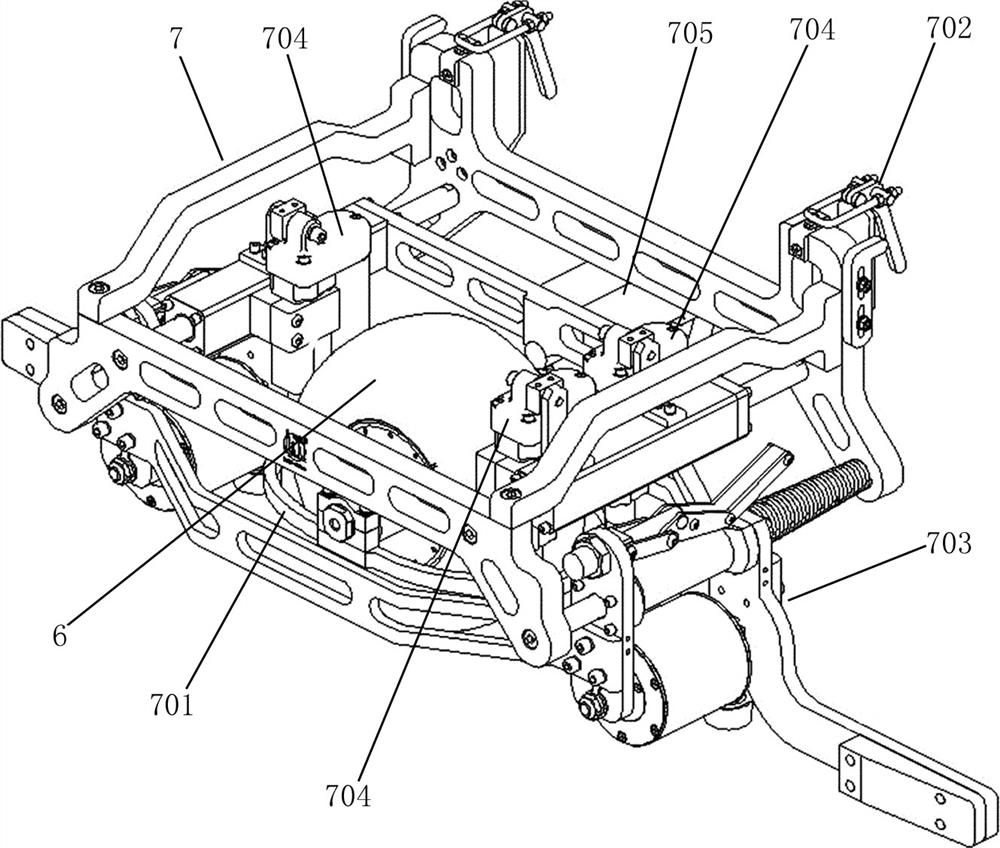

[0027] Step 2: Delineate the centerline of the wheel surface of the wheel 6 along its circumference on the wheel surface of the wheel 6, and then install the wheel 6 on the fixed bracket 701 of the wheel frame 7;

[0028] Step 3: Install the wheel frame 7 on the test block frame so that the wheel surface of the wheel 6 fits the rail surface of the test block 1, and the wheel frame 7 can move along the extension direction of the test block 1;

[0029] Step 4: Adjust the position of the probe wheel 6 through the probe wheel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com