Epoxy glue impregnated paper casing capacitor core insulation performance test sample preparation method

A technology for the capacitance and insulation performance of bushings, which is applied in the measurement of electricity, measurement devices, and measurement of electrical variables, etc. It can solve the problem of the increase in the bubble content of the sample, the large difference between the content ratio of epoxy glue and crepe paper, and the inability of pressure and tension to be equivalent. and other issues to achieve a good effect of equivalence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

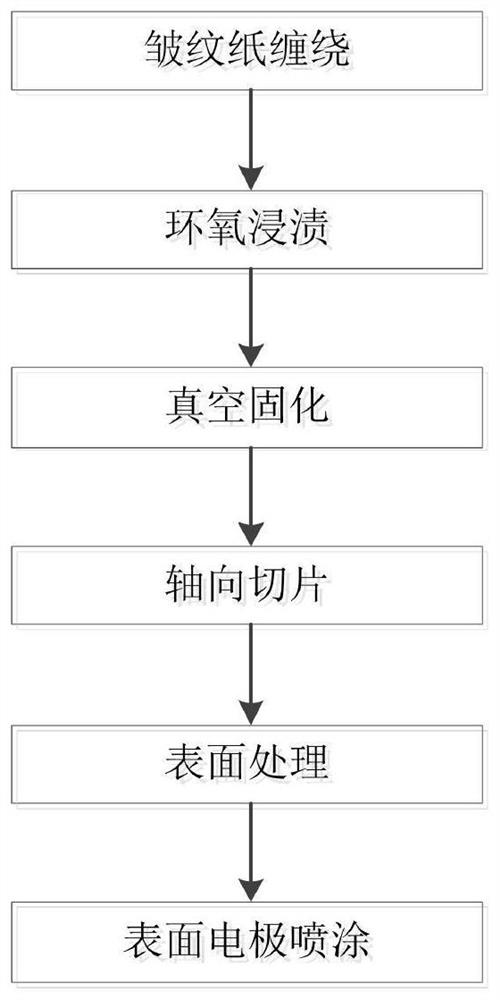

[0029] This embodiment provides a method for preparing samples for insulation performance testing of epoxy glue-impregnated paper casing capacitor cores. The main steps include: ①crepe paper winding, ②epoxy impregnation, ③vacuum curing, ④axial slicing, ⑤ Surface treatment, ⑥ surface electrode spraying.

[0030] ①Crinkle paper winding, under the condition of fixed tension, take the cylindrical rod as the axis, wind the crepe paper clockwise or counterclockwise on the outside of the cylindrical rod at a constant speed, until the diameter meets the requirements, stop the winding of the crepe paper and fix it The outermost layer of crepe paper to prevent loosening. The tensile force is not less than 100N, and the paper wrinkle / epoxy glue content ratio can be controlled by the magnitude of the tensile force; the diameter of the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com