Stress-induced high birefringence ultra-large mode field photonic crystal fiber

A technology of photonic crystal fiber and high birefringence, which is applied in polarizing fiber, cladding fiber, optical waveguide and light guide, etc. It can solve the problem that photonic crystal fiber is difficult to achieve fiber single-mode transmission and high birefringence polarization-maintaining photonic crystal fiber and other problems, to achieve the effect of easy operation and increasing the limit loss ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

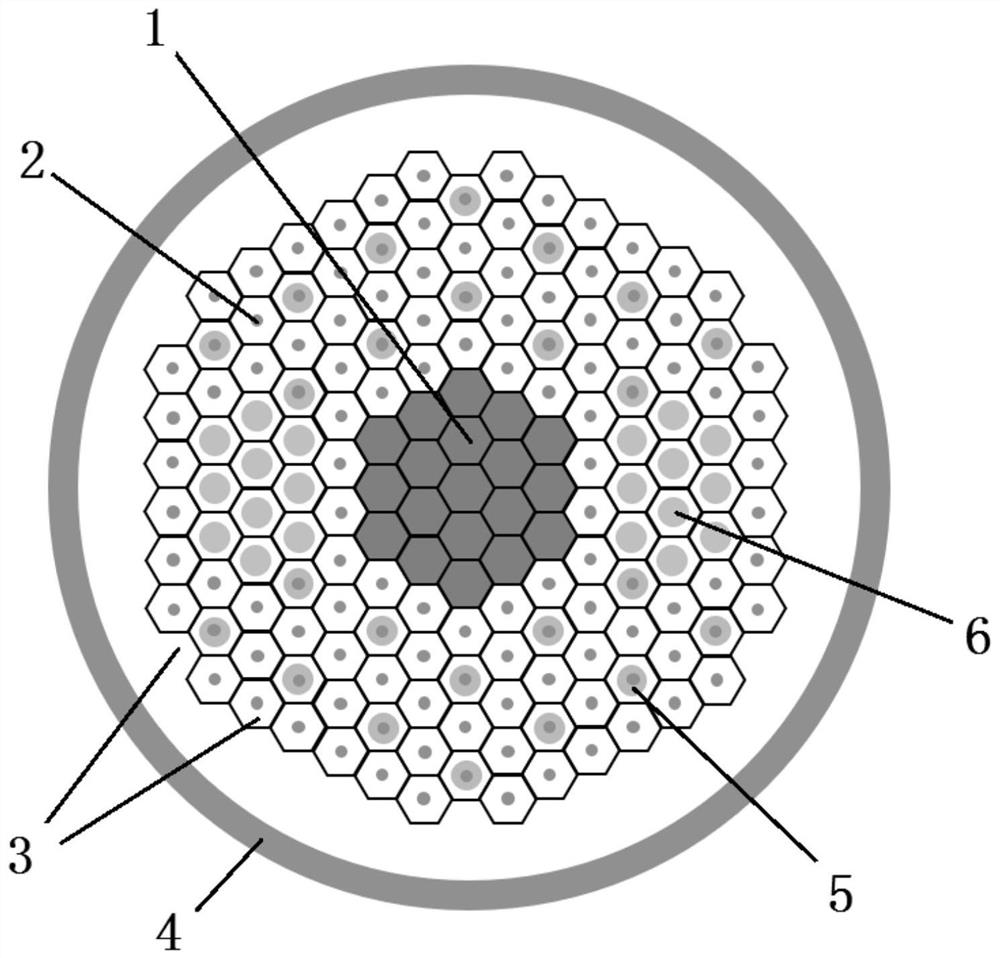

[0088] The 19 air holes are replaced by the fiber core 1, the high-order mode filtering structure 5 is added, and the stress material introduced in the stress zone 6 is a boron rod. The photonic crystal fiber structure is as follows figure 1 shown.

[0089] 1) PCF fiber structure parameters:

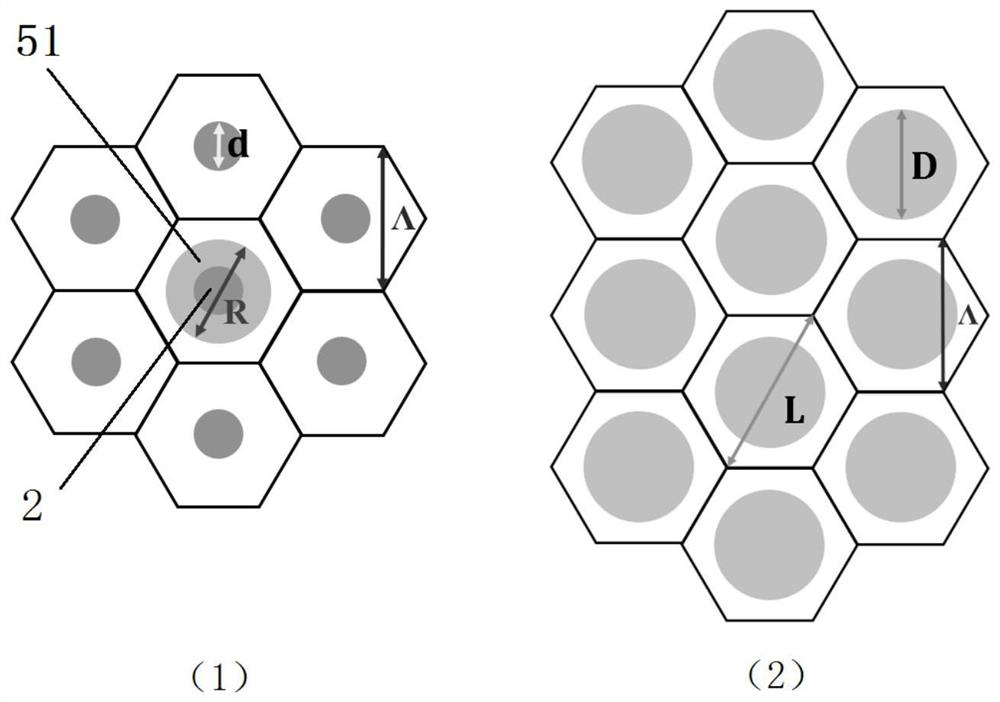

[0090] Air hole diameter d=1~5μm, hole spacing Λ=14.5~25μm, d / Λ=0.04~0.5; fiber core 1 replaces three layers of air holes, that is, silica with 19 air holes; Edge shape, no gaps in the fiber arrangement when the fiber is drawn, the edge is equal to 5 / 2Λ, and the core diameter is 5.5Λ;

[0091] The air hole cladding around the fiber core 1 has five layers of air holes 2, the cladding substrate 3 is silicon dioxide, and the air holes 2 are in a triangular lattice structure; the air hole cladding is added with a high-order mode filtering structure 5, and the high-order mode filtering structure The filter structure 5 is composed of a plurality of annular structures 51 outside the air holes...

Embodiment 2

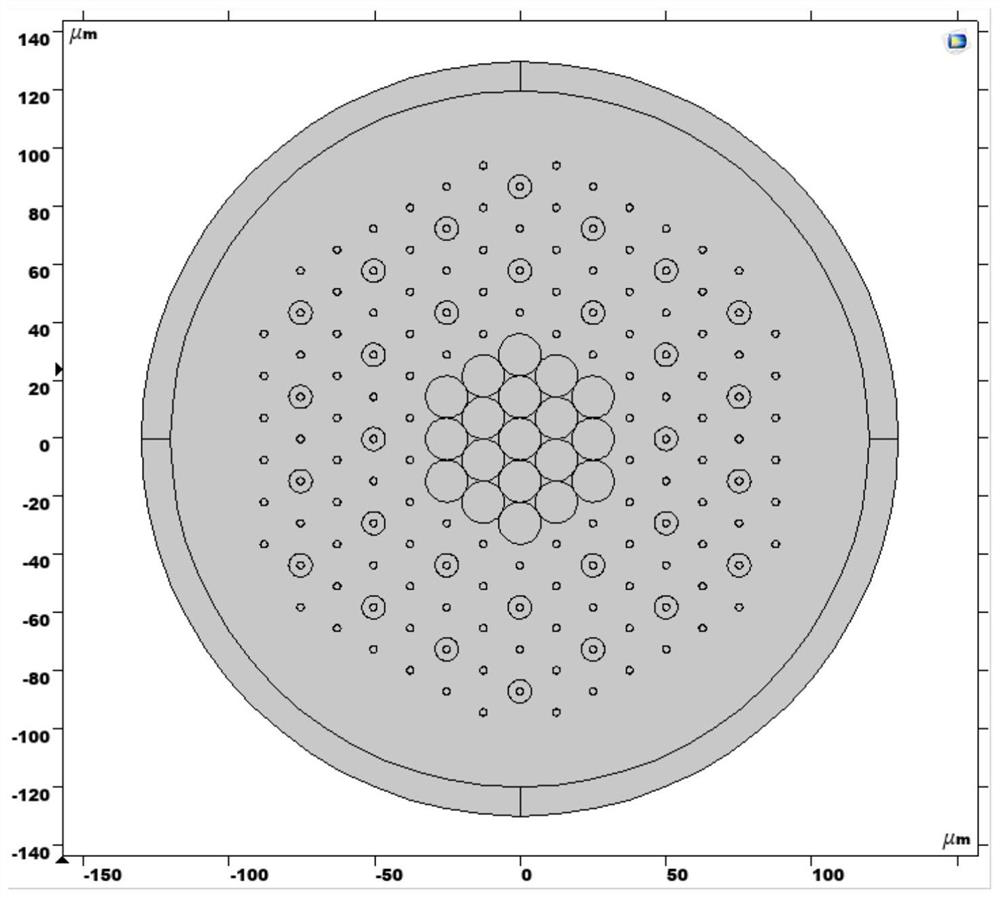

[0111] The 19 air holes are replaced by the fiber core 1, and the stress material introduced in the stress region 6 is a boron rod. The photonic crystal fiber structure is as follows Image 6 shown.

[0112] 1) PCF fiber structure parameters:

[0113] Air hole diameter d=1~5μm, hole spacing Λ=14.5~25μm, d / Λ=0.04~0.5; fiber core 1 replaces three layers of air holes, that is, silica with 19 air holes; Edge shape, the fiber is arranged without gaps when the fiber is drawn, the edge is equal to 5 / 2Λ, and the core diameter is 5.5Λ;

[0114] The air hole cladding around the fiber core 1 has five layers of air holes 2, the cladding substrate 3 is silicon dioxide, and the air holes 2 are in a triangular lattice structure;

[0115] The boron rod introduced into the stress zone 6 in the air hole cladding includes a boron rod core and a quartz outer layer. The diameter of the boron rod core is D=12-15 μm. The larger the number of boron rods, the better the polarization-maintaining effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com