Bendable all-solid-state single-polarization photonic band gap optical fiber with core diameter of more than 45 microns

A photonic bandgap, all-solid-state technology, applied in glass fibers, clad fibers, optical waveguides, etc., can solve the problems of active fibers that cannot meet the core area, and achieve nonlinear effects and low single-mode transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

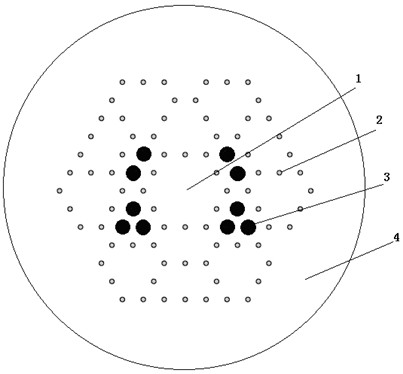

[0011] Such as figure 1 As shown, the active or passive core region 1 is made of active doped quartz material, the fiber core is 7-cell core, and the fiber cladding base region 4 is made of quartz material. The high-refractive-index rod region 2 is a mixed region of the high-refractive-index germanium-doped rod array of the three-cell cladding core and the high-refractive-index germanium-doped rod array of the two-cell cladding core, a symmetrical pair of triplet cladding near the fiber core The layer core and the two-cell cladding core are the stressed boron rod array region 3, the center-to-center spacing of the high-refractive index germanium-doped rods is 13.2 μm, the diameter of the high-refractive index germanium-doped rods is 2.9 μm, and the high-refractive index germanium-doped rods are relatively The relative refractive index difference is 0.0012. The relative refractive index difference between the stressed boron rod and quartz is 0.008, the diameter of the stressed...

Embodiment 2

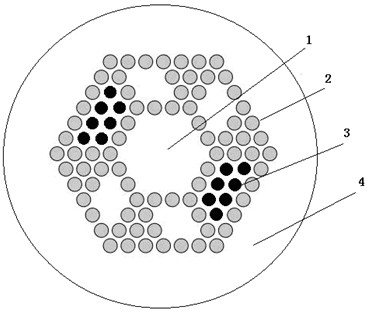

[0013] Such as figure 2 As shown in , the material of the fiber core region is quartz material, the fiber core is 19-cell core, the fiber substrate material is quartz material, and the fiber high-refractive index rod region 2 is a four-celled diamond cladding core high-refractive index germanium-doped rod array , the stressed boron rod array region 3 is a boron rod region symmetrical on both sides of the fiber core. The refractive index of the high-refractive-index germanium-doped rod is graded-index type, and the relative refractive index difference between the peak refractive index and quartz is 0.03. The diameter of the high-refractive-index germanium-doped rod is 9.4 μm, the distance between adjacent high-refractive-index germanium-doped rods is 11.9 μm, the relative refractive index difference between the stressed boron rod and quartz is 0.008, and the diameter of the stressed boron rod is 7.2 μm. The spacing between adjacent boron rods is 11.9 μm.

[0014] This hetero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com