A high-efficiency heat-conducting heat pipe reactor fuel element

A fuel element and reactor technology, which is applied in the reactor-related fields, can solve the problems of reducing the share of nuclear fuel, low thermal conductivity, unfavorable small and lightweight design of the reactor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

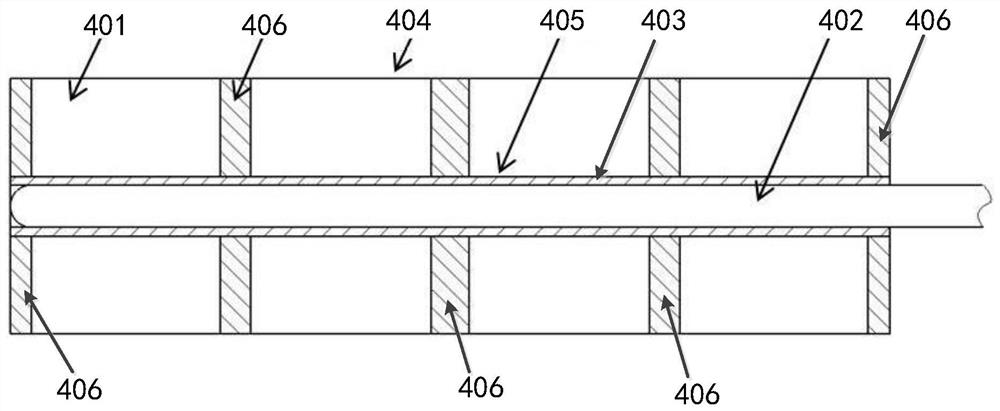

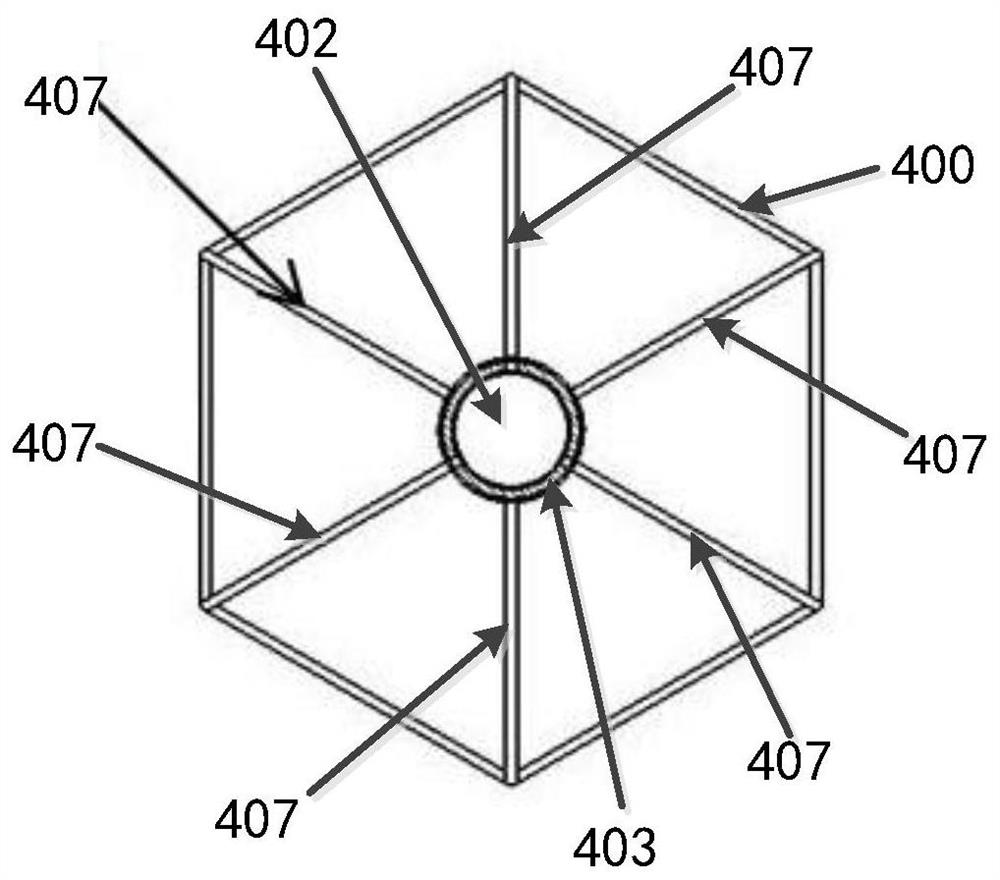

[0030] like Figure 1-Figure 3 As shown, a high-efficiency heat-conducting heat pipe reactor fuel element in this embodiment includes a nuclear fuel 401, a cladding tube 400, a heat pipe 402, and a heat-conducting ring 403. The cladding tube 400 includes a sleeved inner wall 405 and an outer wall 404, so The heat pipe 402 is placed in the inner hole of the inner wall 405, the heat conduction ring 403 is sleeved outside the heat pipe 402 and is located between the heat pipe 402 and the inner wall 405; the inner wall 405 of the cladding tube 400 A number of axial heat conduction plates 407 and a number of radial heat conduction plates 406 are arranged between the outer wall 404, and the axial heat conduction plates 407 and radial heat conduction plates 406 divide the cladding tube 400 into several for filling the nuclear fuel In the fuel area of 401 , stress relief grooves 408 are opened on the axial heat conducting plate 407 .

[0031] In the high-efficiency heat-conducting ...

Embodiment 2

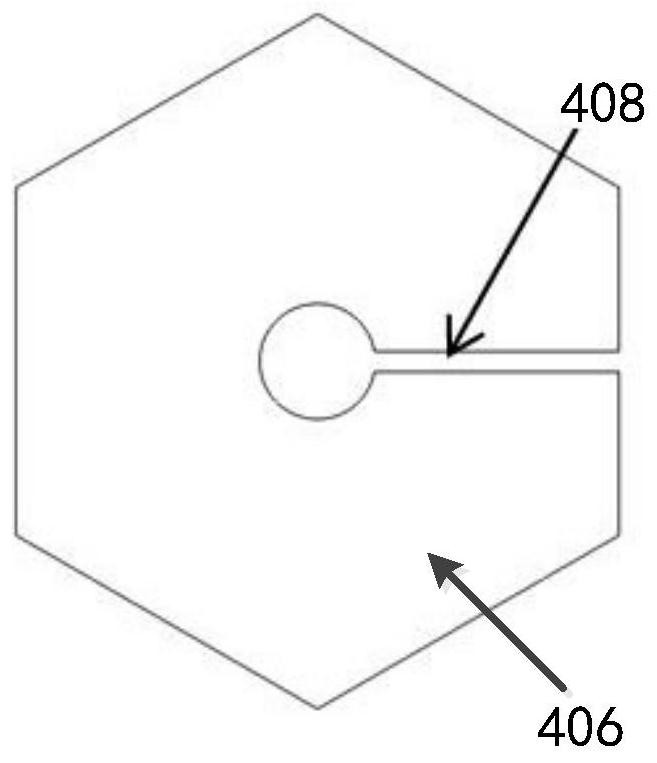

[0033] like Figure 1-Figure 3 As shown, a high-efficiency heat-conducting heat pipe reactor fuel element in this embodiment includes a nuclear fuel 401, a cladding tube 400, a heat pipe 402, and a heat-conducting ring 403. The cladding tube 400 includes a sleeved inner wall 405 and an outer wall 404, so The heat pipe 402 is placed in the inner hole of the inner wall 405, the heat conduction ring 403 is sleeved outside the heat pipe 402 and is located between the heat pipe 402 and the inner wall 405; the inner wall 405 of the cladding tube 400 A number of axial heat conduction plates 407 and a number of radial heat conduction plates 406 are arranged between the outer wall 404, and the axial heat conduction plates 407 and radial heat conduction plates 406 divide the cladding tube 400 into several for filling the nuclear fuel In the fuel area of 401 , stress relief grooves 408 are opened on the radial heat conduction plate 406 .

[0034] like image 3 As shown, the stress re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com