Special tool for live-line removal of bird nest

A special tool and bird's nest technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenient use, bumping equipment by rotating rods, inapplicable dismantling of bird's nests, etc., to achieve the effect of convenient disassembly and assembly and prevention of unnecessary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

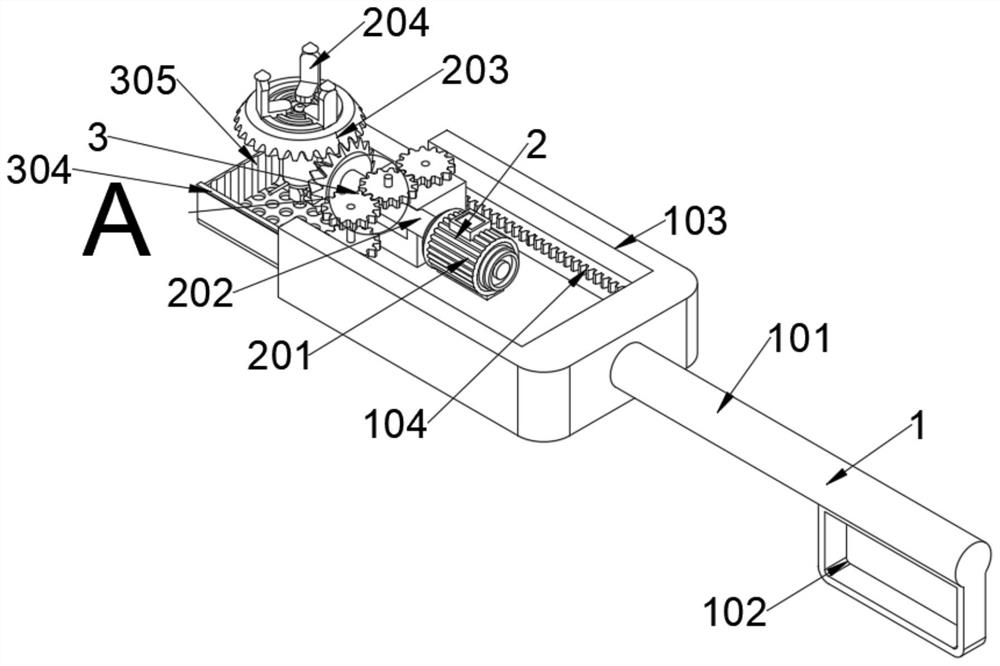

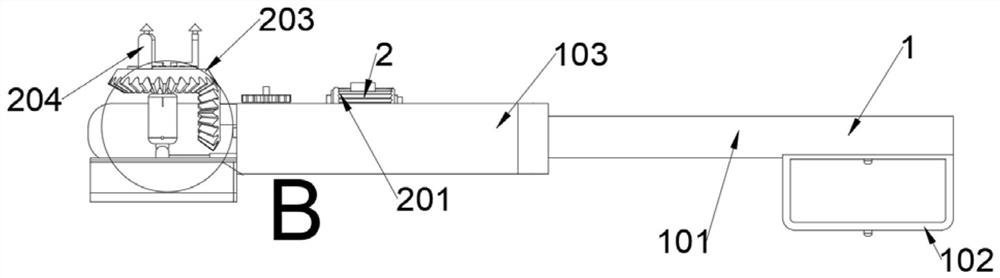

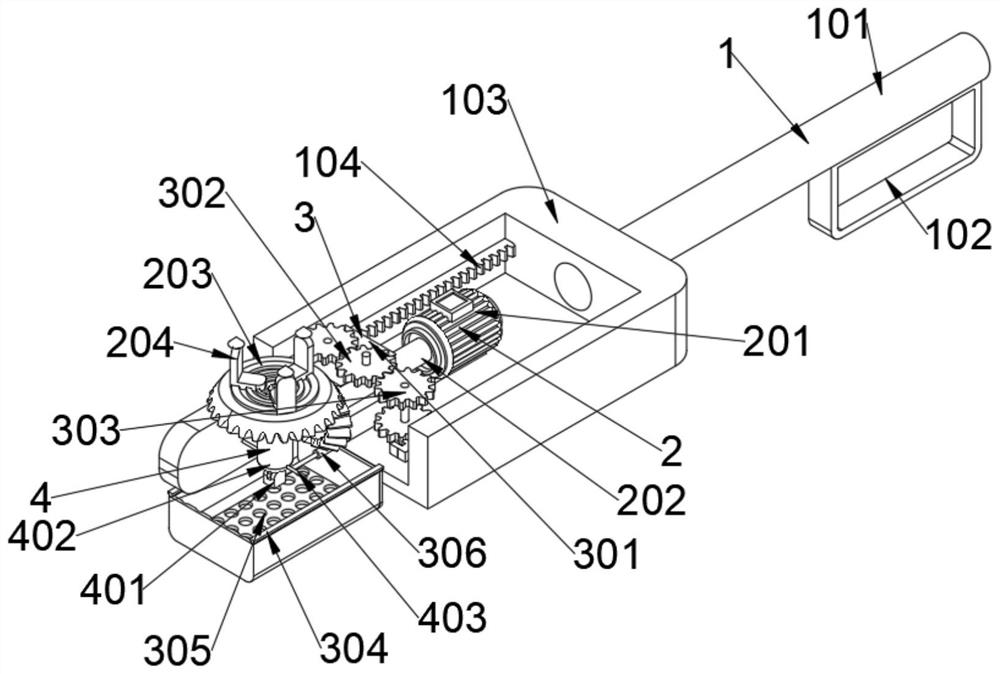

[0059] as attached figure 1 to attach Figure 8 Shown:

[0060] The present invention provides a special tool for removing bird's nest with electricity, including: a support mechanism 1,

[0061] It is characterized in that: the support mechanism 1 is designed as an "L"-shaped structure, and the inner side of the support mechanism 1 is also engaged with the transmission and has a removal mechanism 2;

[0062] The removal mechanism 2, the removal mechanism 2 is a U-shaped structure design, and the overall width of the support mechanism 1 is smaller than the width of the support mechanism 1.

[0063] Wherein, the stepping mechanism 3 includes:

[0064] Stepping block 301, stepping block 301 is a "U"-shaped structure design, and the inside of stepping block 301 is provided with a through longitudinal square groove, and the bottom ends of the two transverse plates of stepping block 301 are horizontally opened with "T" shaped groove, two "T" shaped grooves are parallel to each ...

Embodiment 2

[0094]In this embodiment 2, the difference from embodiment 1 is that the tilting assembly 306 is a cylinder and an air rod, and the tilting assembly 306 is also installed on the left side of the stepping block 301, which can pass through the guide block 401 in the guide mechanism 4 and the air rod. The hinge of the guide shaft 402 realizes the overturning of the removal mechanism 2 at a certain angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com