Automatic return device based on stepping motor

A technology of stepping motor and automatic return, which is applied in the direction of electromechanical devices and electrical components, and can solve the problems of unable to return automatically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples of implementation. It should be understood that the specific examples described here are only used to explain the present invention, not to limit the invention.

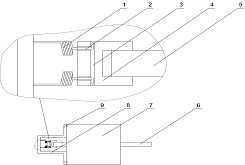

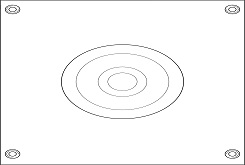

[0010] figure 1 , 2 are the front sectional view and left view of a control frame with adjustable spraying distance, the whole return device consists of torsion spring, axial hole, radial through hole, stepping motor rear shaft bushing, stepping motor Rear shaft, stepper motor power output shaft, stepper motor housing, device housing fixing bracket and fixing bolts are composed.

[0011] When the stepper motor driver receives the pulse signal, the output torque of the stepper motor shaft overcomes the torsion torque of the torsion spring and rotates the corresponding angle according to the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com