Insulating heat-conducting potting electrical element and potting method thereof

A technology of electrical components, insulation and heat conduction, applied in the direction of electrical components, electrical components, electrical equipment casings/cabinets/drawers, etc., can solve problems such as cost increase, achieve cost saving, improve heat conduction effect, and reduce overall shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

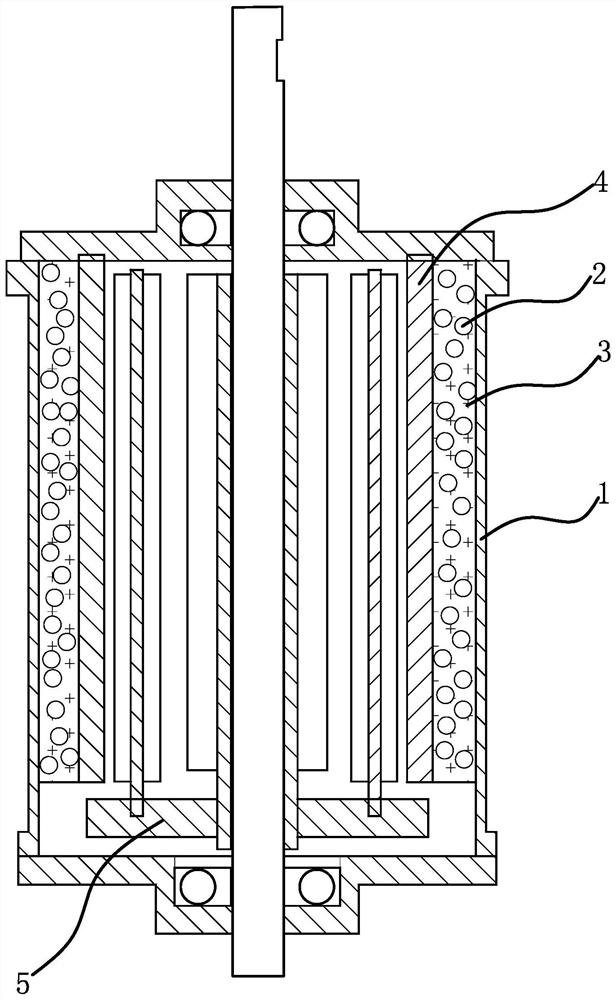

[0040] This embodiment provides an insulating and heat-conducting potting electrical component, such as figure 1As shown, the insulating and heat-conducting potting electrical component is a radial motor, the part to be potted is the stator winding disc 4, and the cavity to be potted is the casing 1 and the stator winding disc 4 of the radial motor. In the formed cavity, the casing 1 is provided with an installation cavity, and the stator winding disk 4 and the rotor 5 rotating on the casing 1 are installed in the installation cavity. The stator winding disk 4 can have an iron core structure or a coil structure without an iron core. , The gap between the stator winding disk 4 and the housing 1 is filled with large-diameter solid particles 2 with an outer diameter of 2mm. The spherical particles are convenient to fill and flow in the gap, and the filling density is uniform. If the stator winding disc 4 is a coil structure, because the large-diameter solid particles 2 have a par...

Embodiment 2

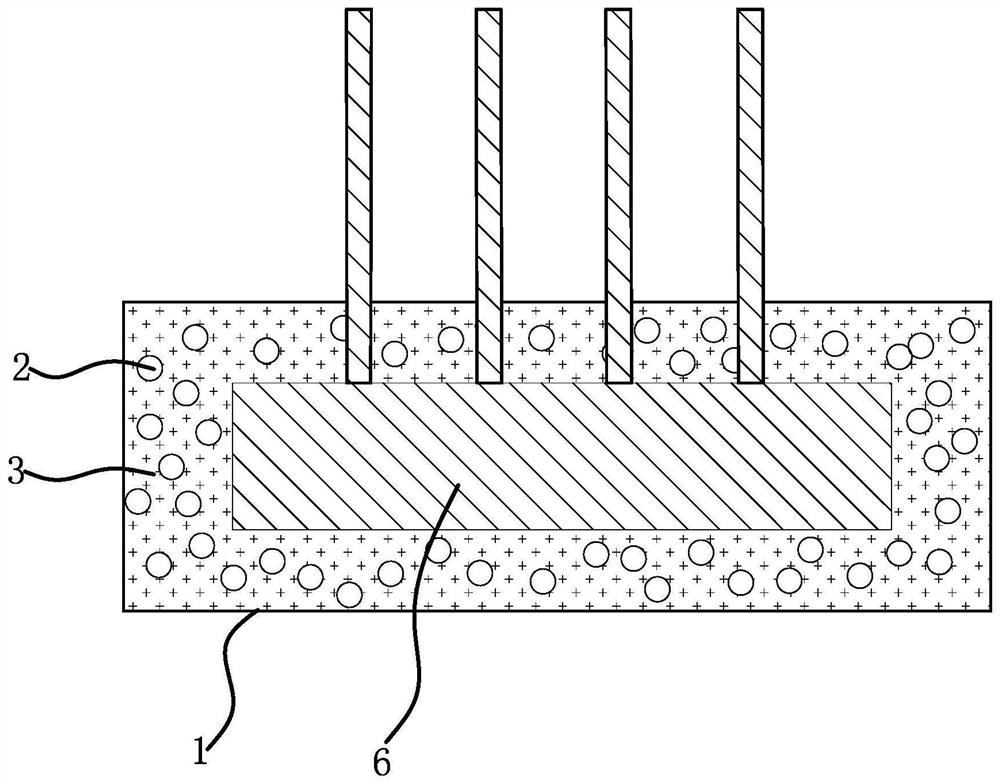

[0042] This embodiment provides an insulating and heat-conducting potting electrical component, such as figure 2 As shown, the insulating and heat-conducting potting electrical component is a capacitor, the part to be potted is the capacitor core 6, and the cavity to be potted is the cavity formed between the shell 1 of the capacitor and the capacitor core 6, The housing 1 is provided with an installation cavity, and the capacitor core 6 is installed in the installation cavity. The gap between the capacitor core 6 and the housing 1 is filled with large-diameter solid particles 2, and the outer diameter of the particles is 2 mm. The spherical particles are convenient to fill in the gap. Internal flow, and uniform filling density. If the gap area between the shell 1 and the capacitor core 6 is large, a mixture of large-diameter solid particles 2 and colloid 3 can be filled. Filling the mixture of large-diameter solid particles 2 and colloid 3 can improve the toughness of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com