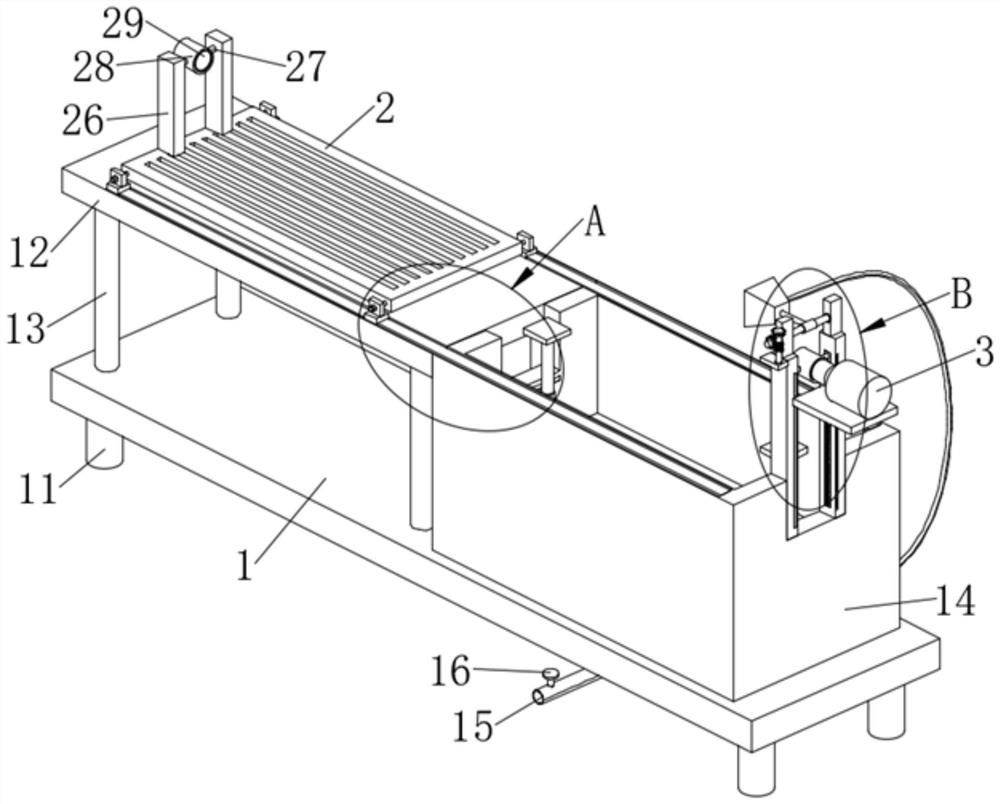

Steam turbine rotor descaling box and descaling method thereof

A technology for steam turbine rotors and casings, which is applied to separation methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of inconvenient cleaning and descaling of steam turbine rotors, waste of labor time, and inconvenient operation. Facilitate cleaning and descaling operations, improve the efficiency of cleaning and descaling, and improve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

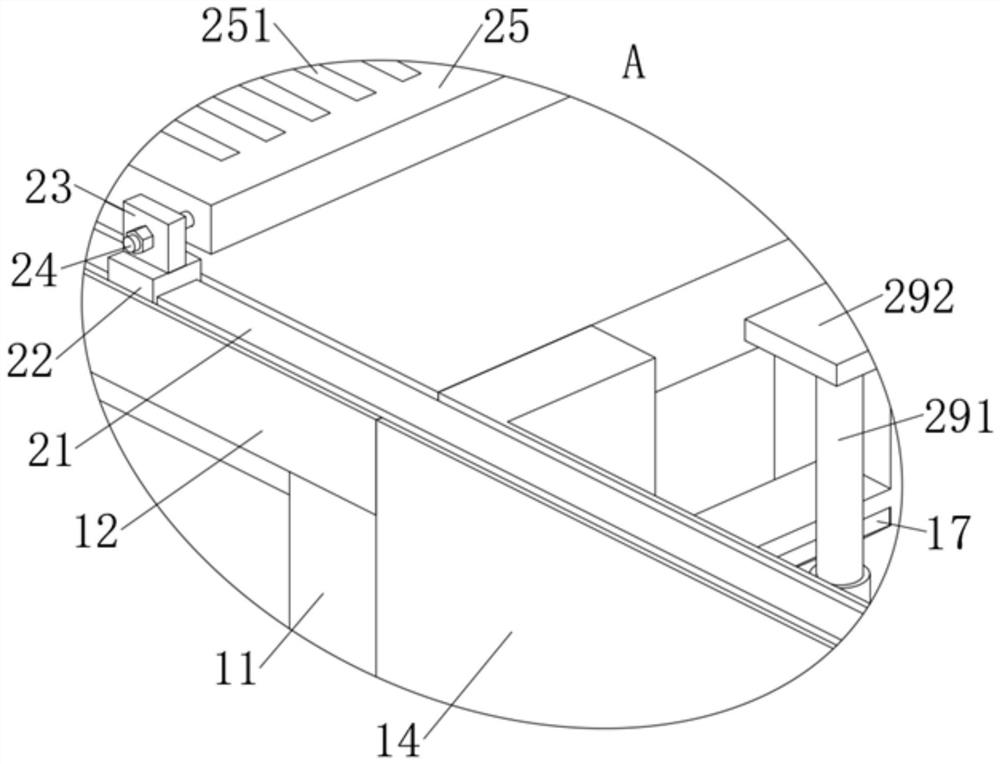

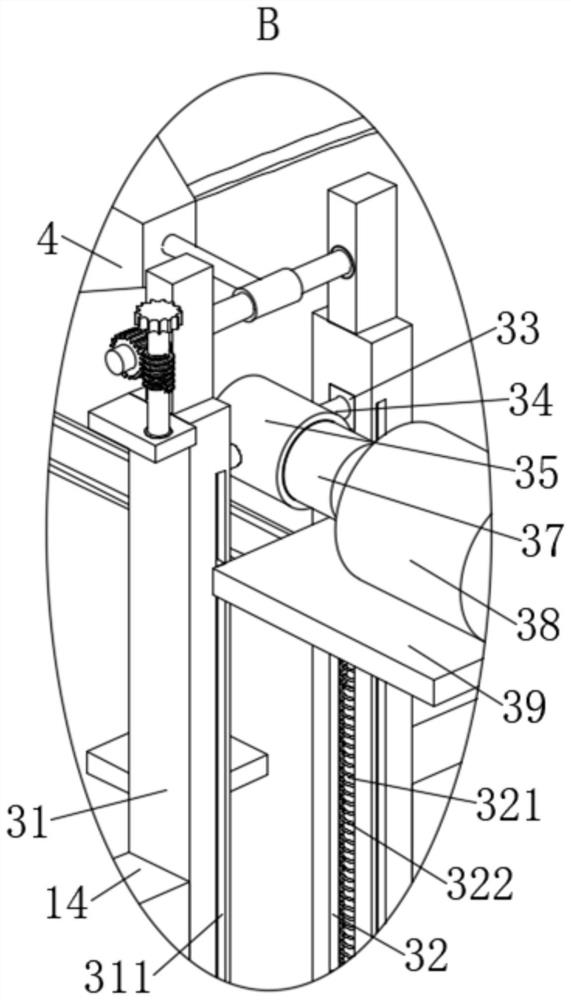

[0042] As an embodiment of the present invention, the pushing mechanism 2 includes a linear electric cylinder 21, the linear electric cylinder 21 is fixedly connected to the console 12, the linear electric cylinder 21 is fixedly connected to the descaling box 14, and the two sets of linear electric cylinders 21 The surface is symmetrically slidably connected with a slider 22. By opening the linear electric cylinder 21, the linear electric cylinder 21 can drive the slider 22 to move horizontally. The upper surface of the slider 22 is fixedly installed with a first fixed plate 23. One side threaded rotation is connected with fastening bolt 24, and between fastening bolt 24, thread clip is connected with moving plate 25, and through knob fastening bolt 24, can realize the fixation and separation of moving plate 25 and fastening bolt 24 conveniently, The upper surface of the moving plate 25 is symmetrically fixed with the first vertical plate 26, and the moving plate 25 can drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com