Device for handling printing plate on printing press

A printing plate and printing machine technology, applied to printing machines, general parts of printing machinery, printing, etc., to achieve the effect of saving assembly and adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

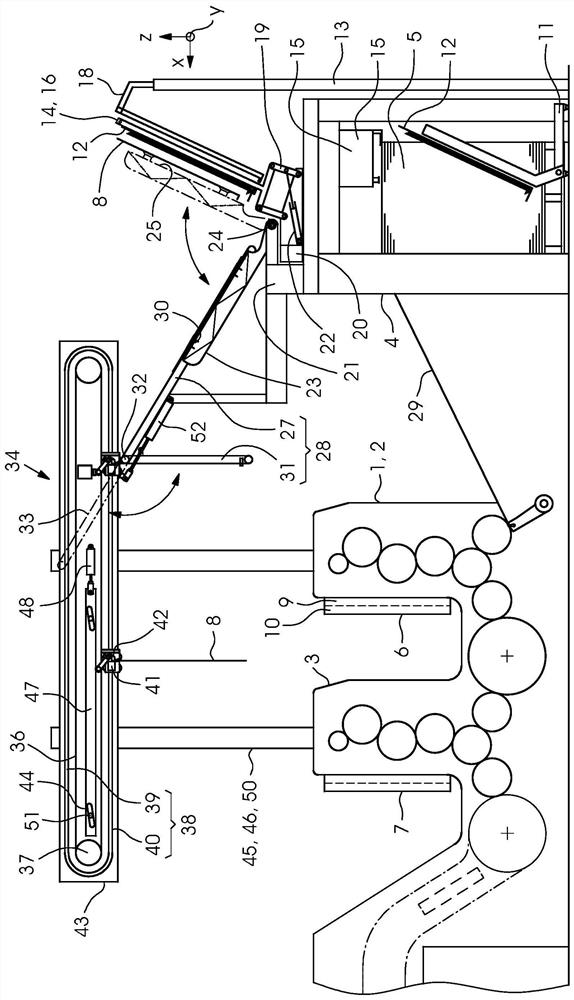

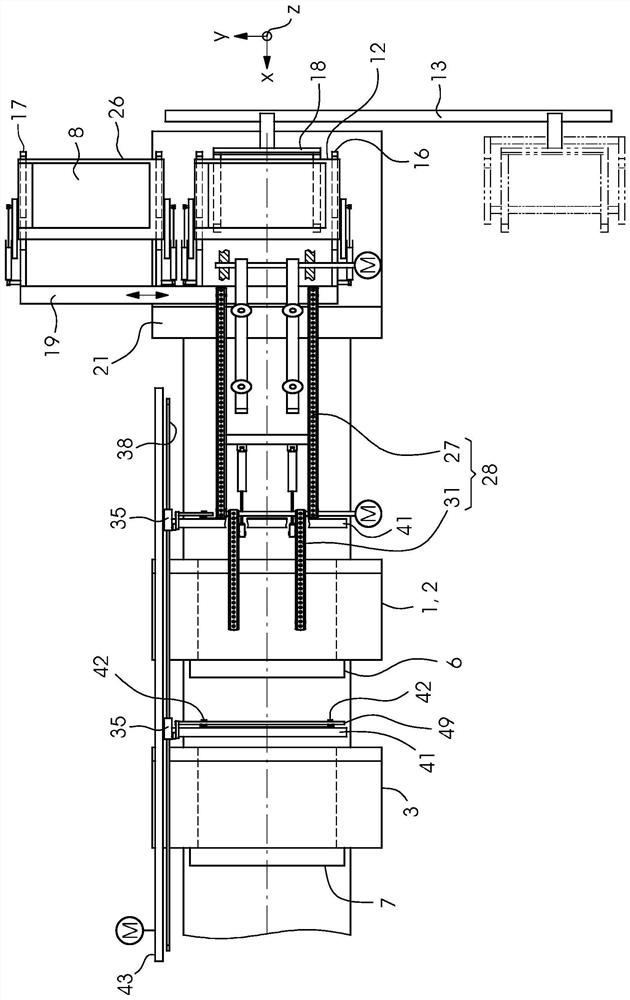

[0019] The printing press 1 comprises printing units 2 , 3 arranged in a row for offset printing on sheets which form a stack 5 in a feeder 4 . Each printing unit 2, 3 is equipped with a plate changer 6, 7 for a printing plate 8, which has a shaft 9 for a new printing plate 8 (so-called new printing plate) and a A shaft 10 for used printing plates 8 (so-called old printing plates). The printing press 1 is combined with a printing plate logistics system which conveys these printing plates 8 to the plate changers 6 , 7 and back again after they have been used. An operator removes the pallet 12 with the printing plates 8 therein from the ground transport device 11 and delivers the pallet 12 to the pallet lifting device 13 .

[0020] The orthogonal coordinate system in the drawing comprises the vertical direction z and the horizontal directions x, y, where x corresponds to the longitudinal direction of the printing press 1 and y corresponds to the transverse direction of the prin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap