High-efficiency road crack treatment device for road engineering

A treatment device and road technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of low dust collection efficiency, concentration, and poor cleaning effect, and achieve the effect of comprehensive cleaning, good cleaning effect, and convenient washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

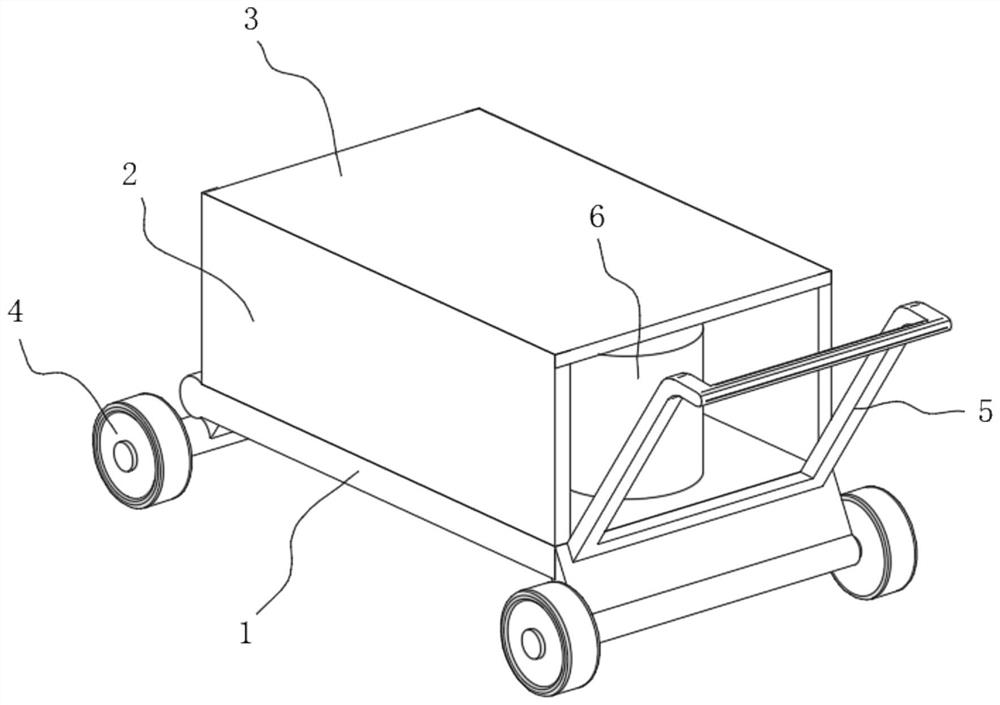

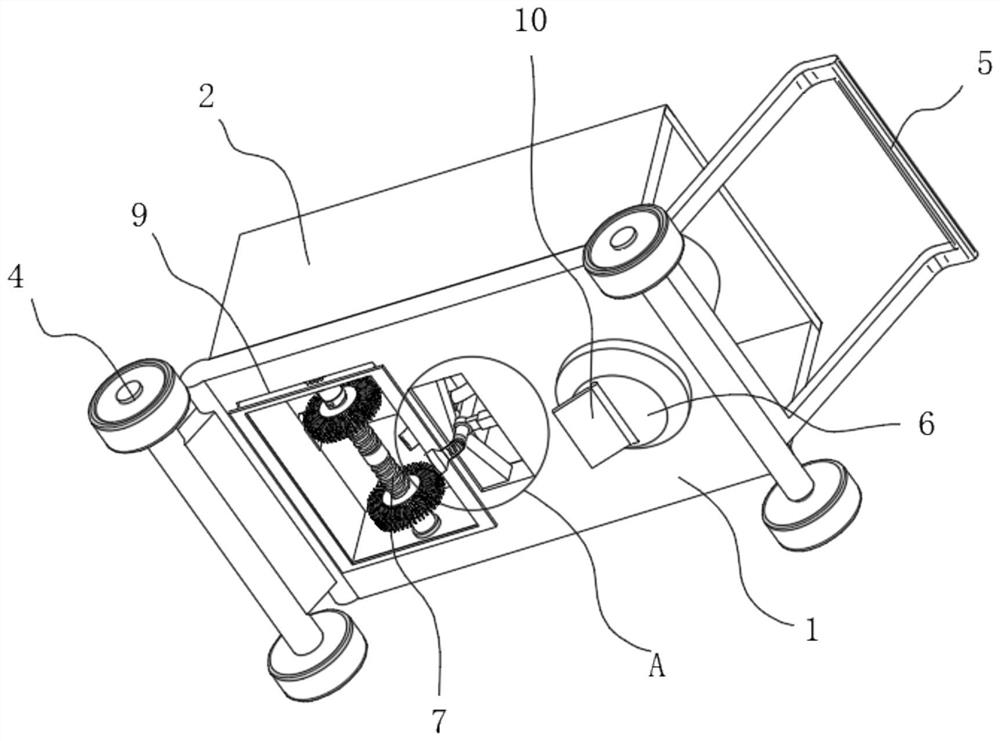

[0030] see Figure 1-7 , the present invention provides a technical solution: a high-efficiency treatment device for highway cracks for highway engineering, comprising a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a vertical plate 2, the top of the vertical plate 2 is movably connected with a top plate 3, and the bottom of the bottom plate 1 The four corners of the bottom are movably connected with rollers 4, the right side of the bottom plate 1 is fixedly connected with a push handle 5, one side of the bottom plate 1 is fixedly connected with a discharge bucket 6, one side of the bottom plate 1 is provided with a cleaning device 7, and the top of the bottom plate 1 is located in A full-scale spray device 8 is fixedly connected to the left side of the discharge bucket 6, a leak hole 9 is opened inside the bottom plate 1, a water tank 15 is fixedly connected to the top of the bottom plate 1 and is located on the right side of the full-scale spray devi...

Embodiment 2

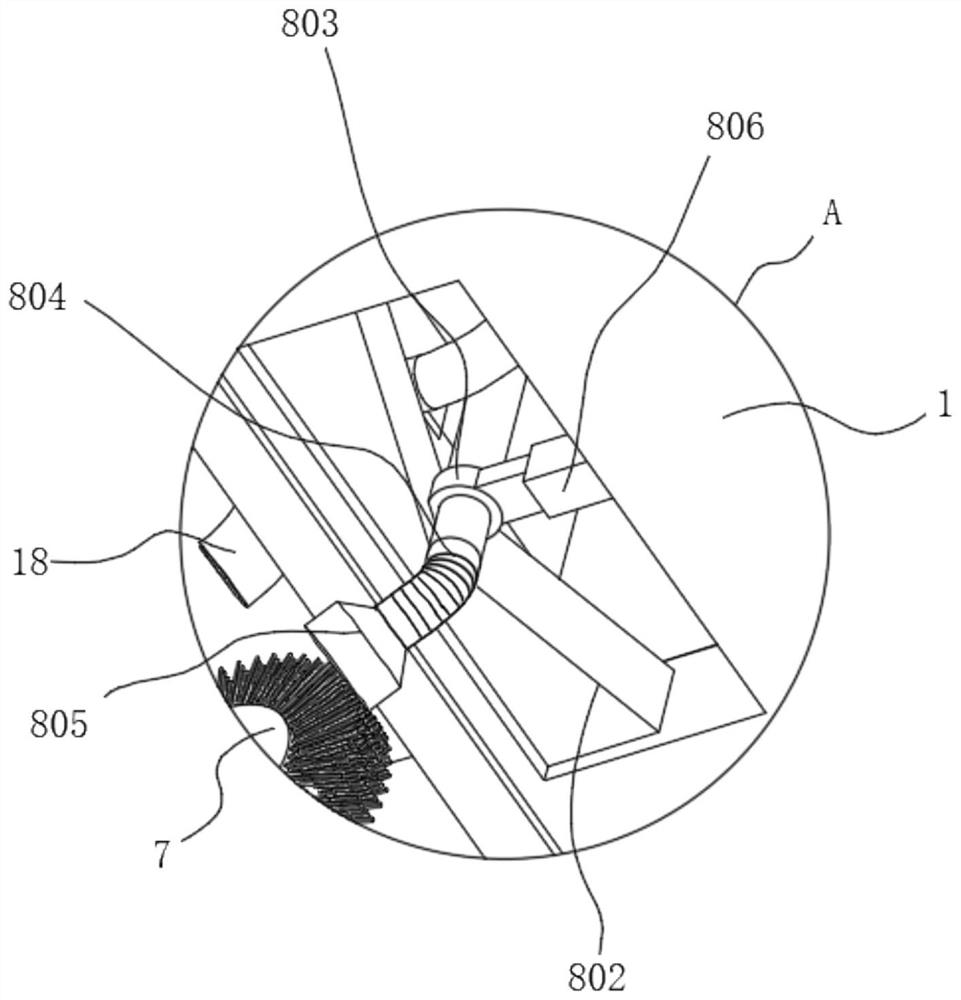

[0034] see Figure 1-7 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the cleaning device 7 includes a horizontal plate 701, a motor one 702 is fixedly connected to the top of the horizontal plate 701, and a cam 703 is rotatably connected to one side of the motor one 702. The bottom of the cam 703 is provided with a moving plate 704, the bottom of the moving plate 704 is fixedly connected with a moving frame 705, the outer wall of the moving frame 705 is fixedly connected with a slide plate 706, and the inner wall of one side of the moving frame 705 is fixedly connected with a motor two 707, the motor two One side of gear 707 is rotatably connected with gear one 708, the bottom of gear one 708 is meshed with gear two 709, one side of gear two 709 is rotatably connected with bidirectional screw 710, and the outer wall of bidirectional screw 710 is rotatably connected with cleaning brush 711, The outer wall is slidingly conne...

Embodiment 3

[0037] see Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the bottom of the discharge bucket 6 is hinged with a discharge plate 10, and the left side of the discharge plate 10 is provided with a groove 11. A tension spring 12 is fixedly connected to the inner wall of the right side of the groove 11 , a slider 13 is fixedly connected to the left side of the tension spring 12 , and a hydraulic cylinder 14 is hinged on the top of the slider 13 . Bottom outer wall hinged.

[0038] In this embodiment, the set discharge plate 10 is used to discharge the repair fluid inside the discharge bucket 6. When the hydraulic cylinder 14 is activated, the slider 13 moves along with it. At this time, the tension spring 12 is gradually stretched and tightened. Automatic reset, the discharge plate 10 is easy to rotate up and down, and the opening at the bottom is easy to adjust the size during rotation. When repairing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com