Ceramic tile joint cleaning machine

A seam cleaning machine and ceramic tile technology, which is applied in the direction of construction and building construction, can solve the problems of falling back into the gaps of tiles, sand and dust falling back into the gaps of tiles, etc., and achieve the effect of cleaning and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

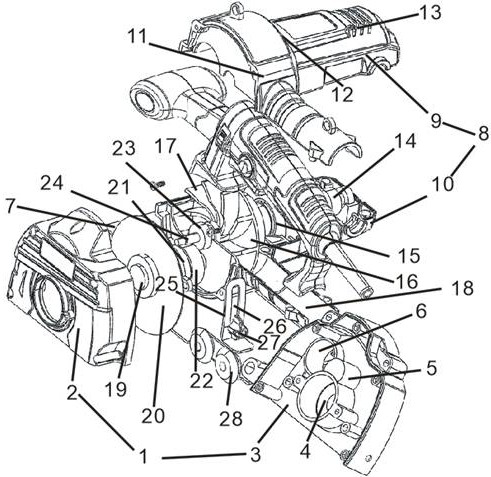

[0018] Please refer to figure 1 , a kind of ceramic tile seam cleaning machine provided in this embodiment includes a machine head 1, a fuselage 8, a bottom plate 7 and a dust suction device, the above-mentioned machine head 1 is arranged at the left end of the fuselage 8, and the bottom plate 7 is arranged at the bottom of the machine head 1, and the above-mentioned The machine head 1 includes a machine head base 3 and a saw blade guard 2. The machine head base 3 and the saw blade guard 2 are fastened to each other and fixed by bolts. The bottom opening of the above machine head 1 is hollow inside, and the bottom of the above machine head base 3 is End center has transmission gear chamber 4, has drive gear chamber 5 on the headstock 3 above transmission gear chamber 4, and transmission gear chamber 4 communicates with drive gear chamber 5, and also has on the headstock 3 of drive gear chamber 5 inner side. There is a dust suction port 6. Of course, the above-mentioned transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com