Fuel cell system

A fuel cell system and fuel cell technology, which is applied to fuel cells, fuel cell additives, circuits, etc., can solve the problems of poor measurement accuracy, low responsiveness, and untimely correction of gas flow meters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

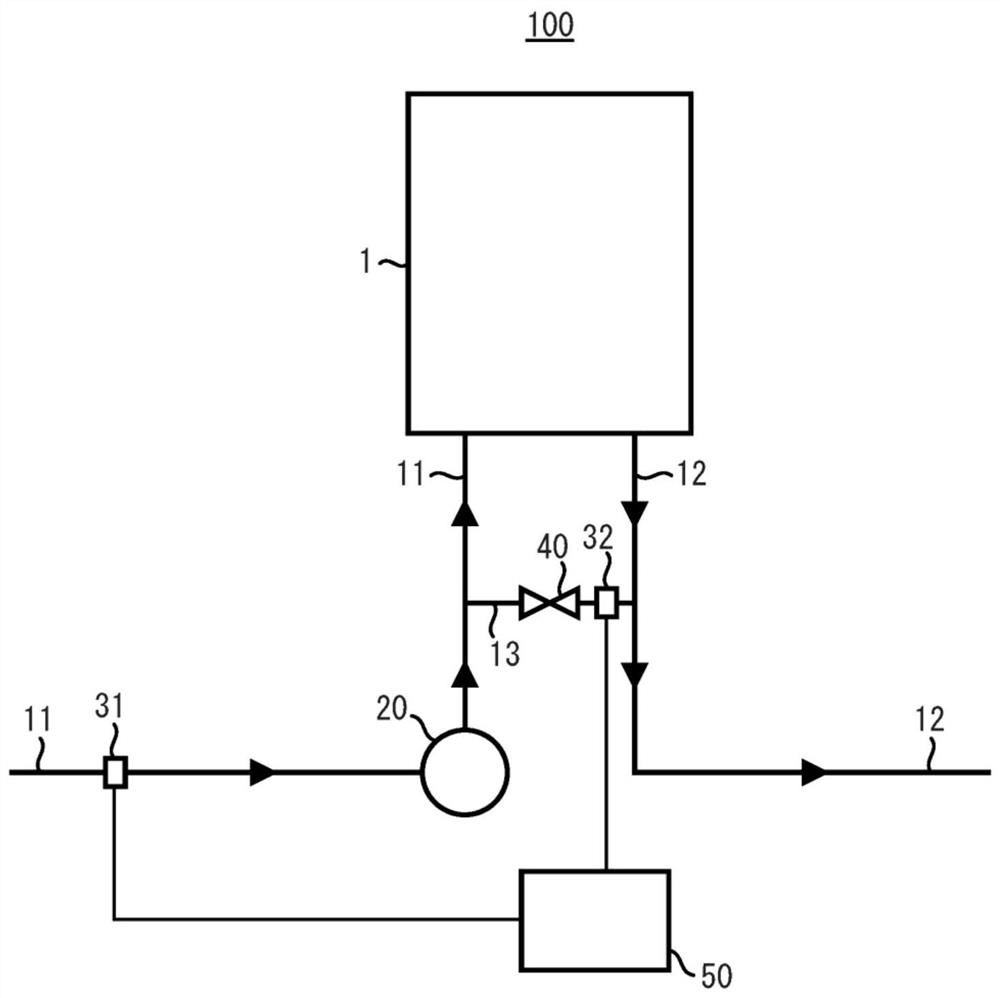

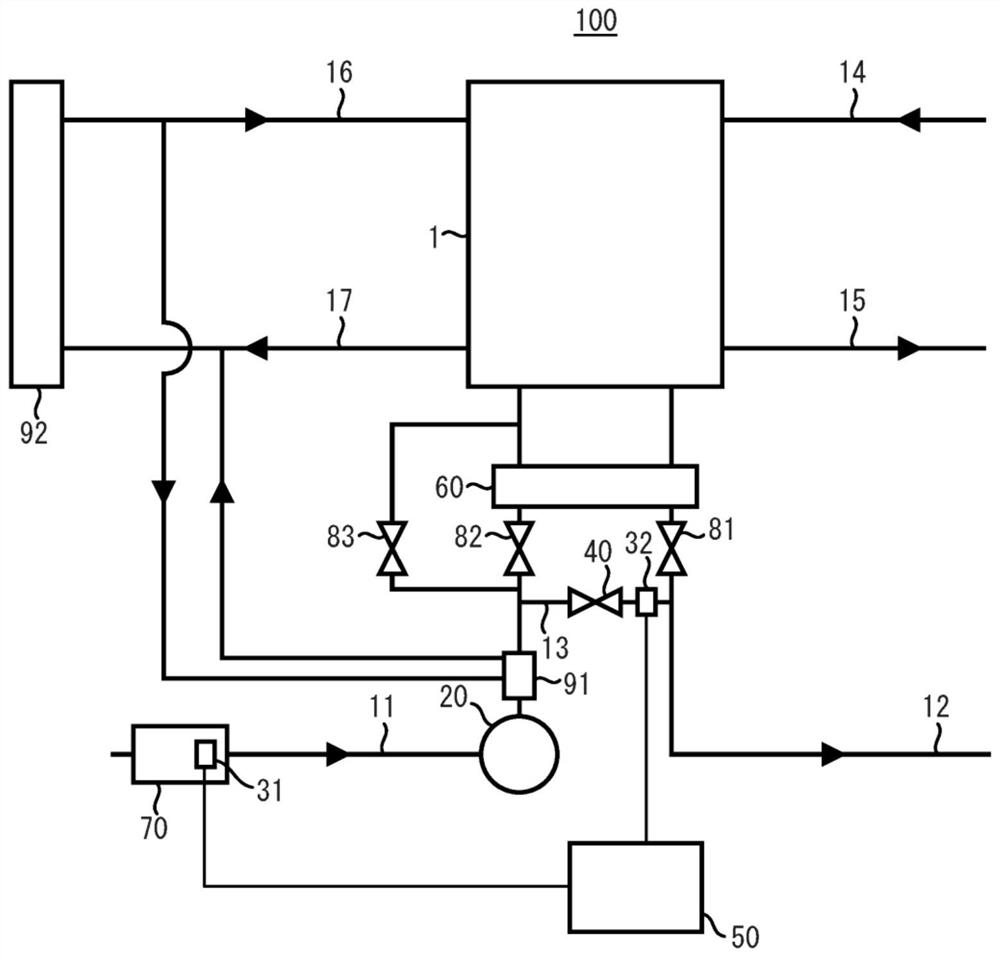

[0030] 1. Fuel cell system

[0031] exist figure 1 The structure of the fuel cell system 100 is briefly shown in . like figure 1 As shown, the fuel cell 100 has: a fuel cell 1;

[0032] The first flow path 11 supplies cathode gas to the fuel cell 1;

[0033] The second flow path 12 discharges the cathode exhaust gas from the fuel cell 1;

[0034] The bypass flow path 13 is branched from the first flow path 11 and connected with the second flow path 12;

[0035] The compressor 20 is arranged in the first flow path 11;

[0036] The first flow meter 31 is set in the first flow path 11;

[0037] The flow regulating valve 40 is arranged in the bypass flow path 13;

[0038] The second flow meter 32 is installed in the bypass channel 13; and

[0039] The control unit 50 controls the flow rate of the cathode gas supplied to the fuel cell 1 .

[0040] The compressor 20 is arranged on the upstream side of the bypass channel 13 .

[0041] The first flow meter 31 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com