Integrated reversible fuel cell water-gas separation structure and reversible fuel cell

A water-gas separation, fuel cell technology, applied in fuel cells, electrical components, circuits, etc., can solve the problems of damaged membrane electrodes, no efficient mode switching strategy, long purge time, etc. Effects of Management and Reaction Catalytic Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

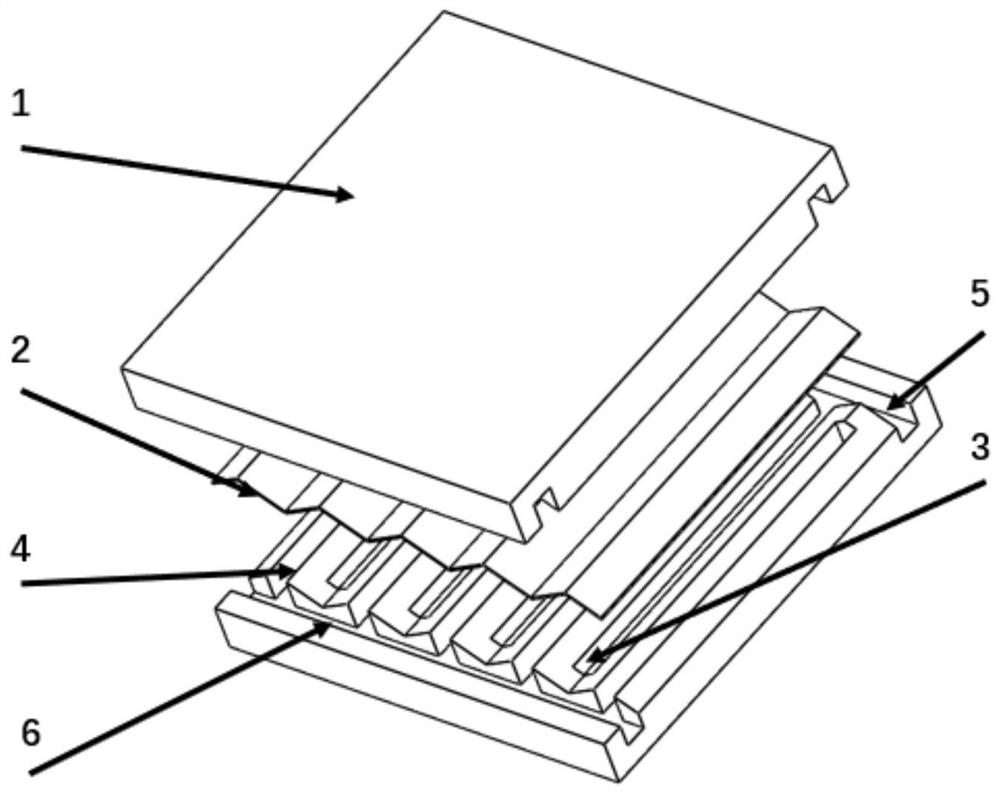

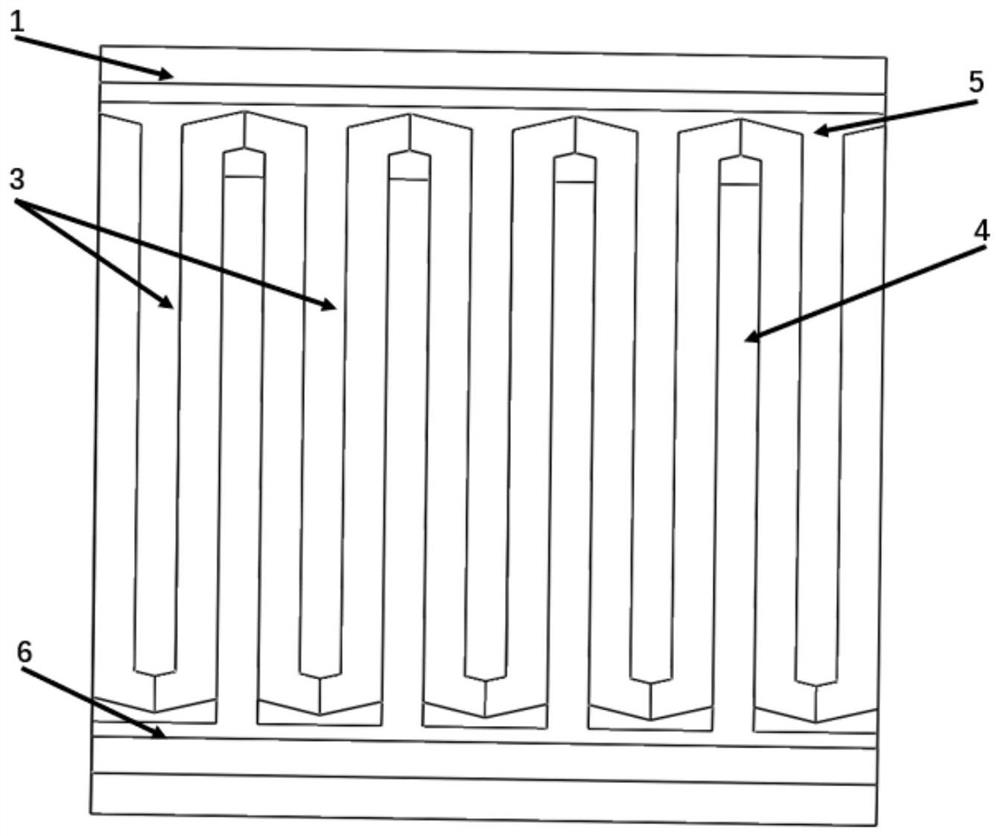

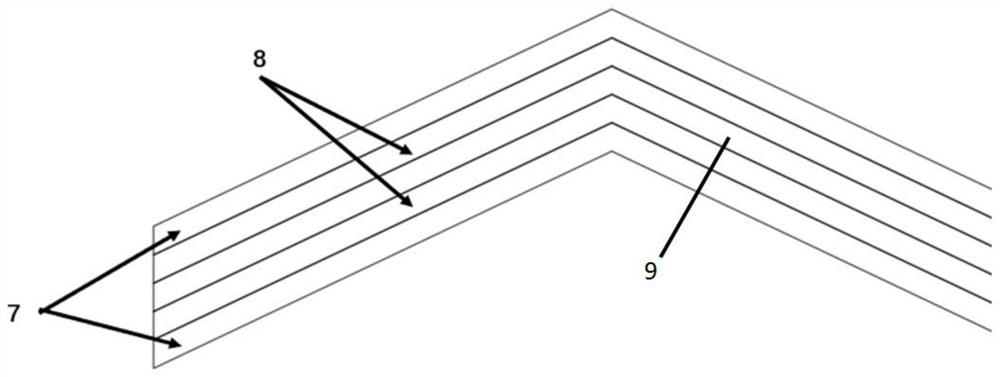

[0036] A reversible fuel cell such as Figure 1-3, including a plate body 1 and a membrane electrode assembly 2, the two sides of the plate body 1 are provided with gravity-driven water-gas separation flow channels, the water-gas separation flow channels are composed of a concave water flow channel 3, an upward convex gas flow channel 4, water The gas distribution area 5 is composed of a gas distribution area 6. The side of the gas distribution area 6 is connected to the parallel upward convex gas flow channel 4, and the other end leads to the outside of the plate body 1. The side of the water distribution area 5 is connected to the parallel downward concave water flow channel 5. The other end leads to the outside of the pole plate body 1 .

[0037] When the reversible fuel cell generates electricity, the gas distribution area 6 distributes the incoming cathode and anode gas, and the water generated by the cathode is collected into the water distribution area 5 through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com