Dry granulation system

A dry granulation and granulation technology, which is applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of incapable expansion of equipment scale, low granulation production capacity, and difficult adjustment of granulate return flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

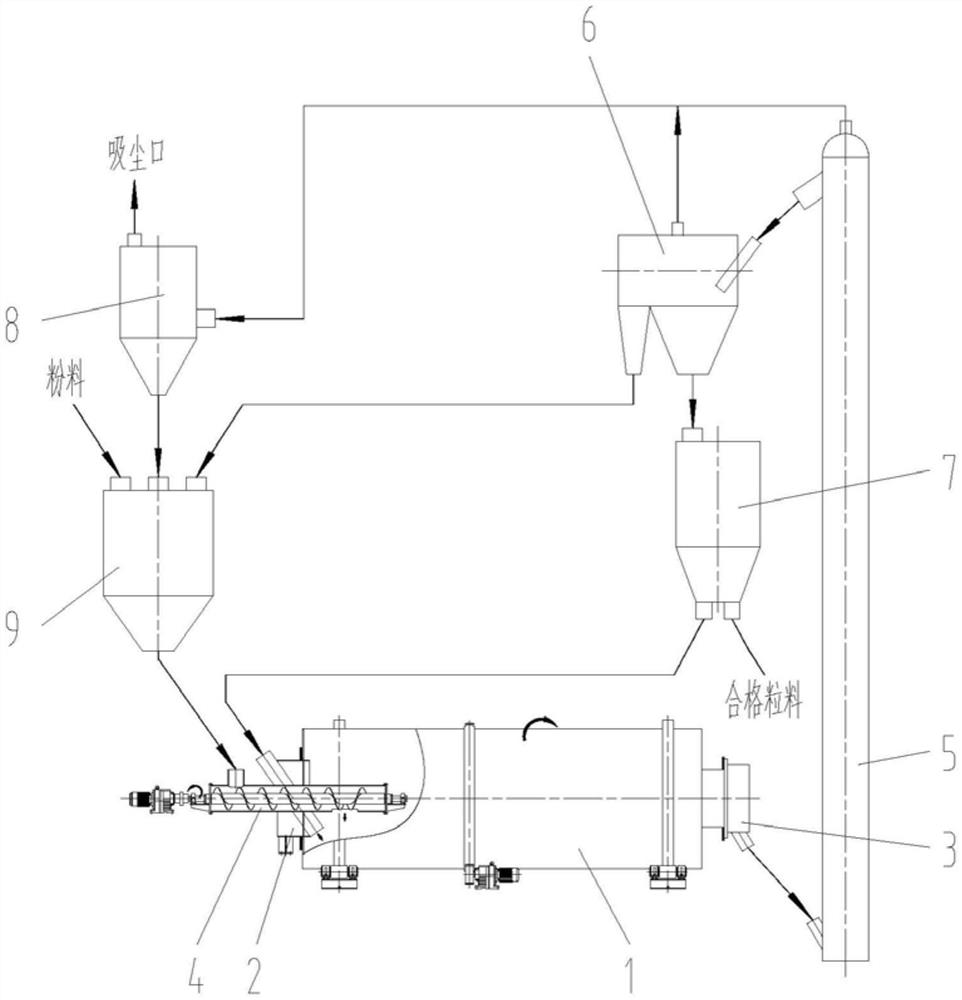

[0007] Figure 1 shows a schematic diagram of the invention. The dry granulation system of the present invention includes a granulator, a hoist, a screening machine, a granulator, a bag filter, and a powder silo, and the granulator is composed of a granulation drum, a feed end, a discharge end, and a screw conveyor. , the specific implementation is as follows:

[0008] The carbon black powder enters the powder silo 9 from the upstream process, and the material in the powder silo 9 enters the screw conveyor 4, and is pushed by the screw conveyor 4 to the inside of the granulation drum 1, and then passes through the granulation drum 1 from the discharge end 3 The discharge port on the top enters the hoist 5, and enters the screening machine 6 after being lifted. After screening, the unqualified materials are returned to the powder bin 9, and the qualified pellets enter the pellet bin 7, and a part of the materials in the pellet bin 7 are automatically fed. The feed port on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com