Preparation method and application of secondary lanthanum carbide modified sludge biochar

A secondary lanthanum carbide and biochar technology, which is applied in the field of functional materials and environmental water treatment, can solve the problems of water eutrophication and achieve the effects of efficient removal, low equipment requirements and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The remaining sludge was dried at 105°C, ground, and sieved; an appropriate amount of sludge powder was placed in a quartz tube furnace, and pyrolyzed at 600°C for 3 hours at a heating rate of 10°C / min to obtain sludge biological charcoal; the obtained sludge biochar and lanthanum nitrate were mixed in a ratio of 1:2 and placed in 40mL ultrapure water, stirred and soaked with a magnetic stirrer at room temperature, left to stand, and dried at 50°C; then the lanthanum was modified Sludge biochar was placed in a quartz tube furnace and pyrolyzed at 600°C for 3 hours at a heating rate of 10°C / min to obtain lanthanum-modified sludge biochar.

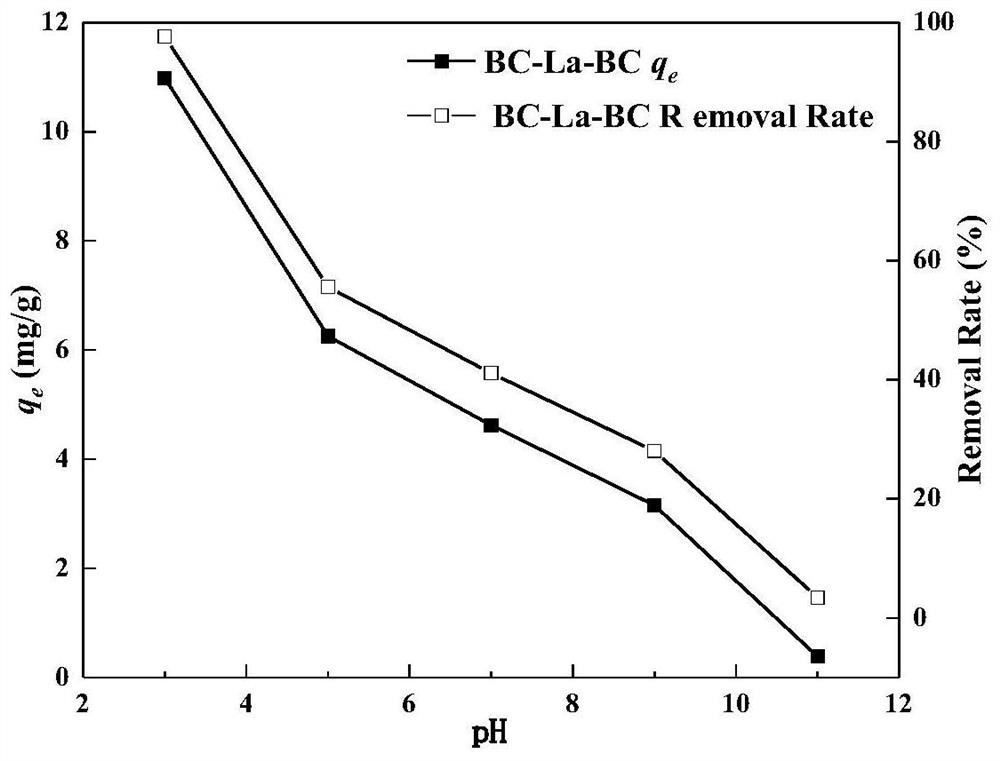

[0019] Effect of pH on the adsorption performance of BC-La-BC: Weigh 20 mg of BC-La-BC and place it in 15 mL of phosphate solution with a concentration of 30 mg / L, and adjust the pH with 0.1M HCl and 0.1M NaOH to be 3, 5, 7, 9 and 11, placed in a shaker for 24 hours to achieve adsorption equilibrium. The mixed solution was filtered t...

Embodiment 2

[0021] The remaining sludge was dried at 105°C, ground, and sieved; an appropriate amount of sludge powder was placed in a quartz tube furnace, and pyrolyzed at 600°C for 3 hours at a heating rate of 10°C / min to obtain sludge biological charcoal; the obtained sludge biochar and lanthanum nitrate were mixed in a ratio of 1:2 and placed in 40mL ultrapure water, stirred and soaked with a magnetic stirrer at room temperature, left to stand, and dried at 50°C; then the lanthanum was modified Sludge biochar was placed in a quartz tube furnace and pyrolyzed at 600°C for 3 hours at a heating rate of 10°C / min to obtain lanthanum-modified sludge biochar.

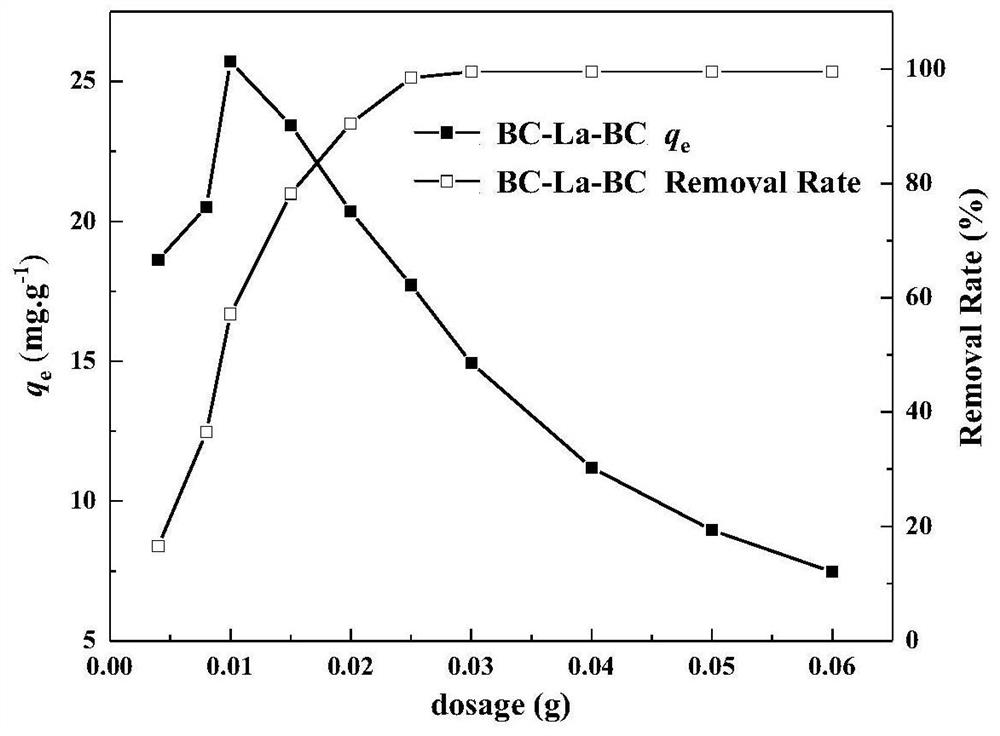

[0022] Determination of dosage: Weigh 4, 8, 10, 15, 20, 25, 30, 40, 50, and 60 mg of BC-La-BC respectively, place them in 15 mL of phosphorus solution with a concentration of 30 mg / L, and adjust the pH Adjusted to 3.0. Such as figure 2 , the adsorption capacity is the largest when the dosage is 10mg.

Embodiment 3

[0024] The remaining sludge was dried at 105°C, ground, and sieved; an appropriate amount of sludge powder was placed in a quartz tube furnace, and pyrolyzed at 600°C for 3 hours at a heating rate of 10°C / min to obtain sludge biological charcoal; the obtained sludge biochar and lanthanum nitrate were mixed in a ratio of 1:2 and placed in 40mL ultrapure water, stirred and soaked with a magnetic stirrer at room temperature, left to stand, and dried at 50°C; then the lanthanum was modified Sludge biochar was placed in a quartz tube furnace and pyrolyzed at 600°C for 3 hours at a heating rate of 10°C / min to obtain lanthanum-modified sludge biochar.

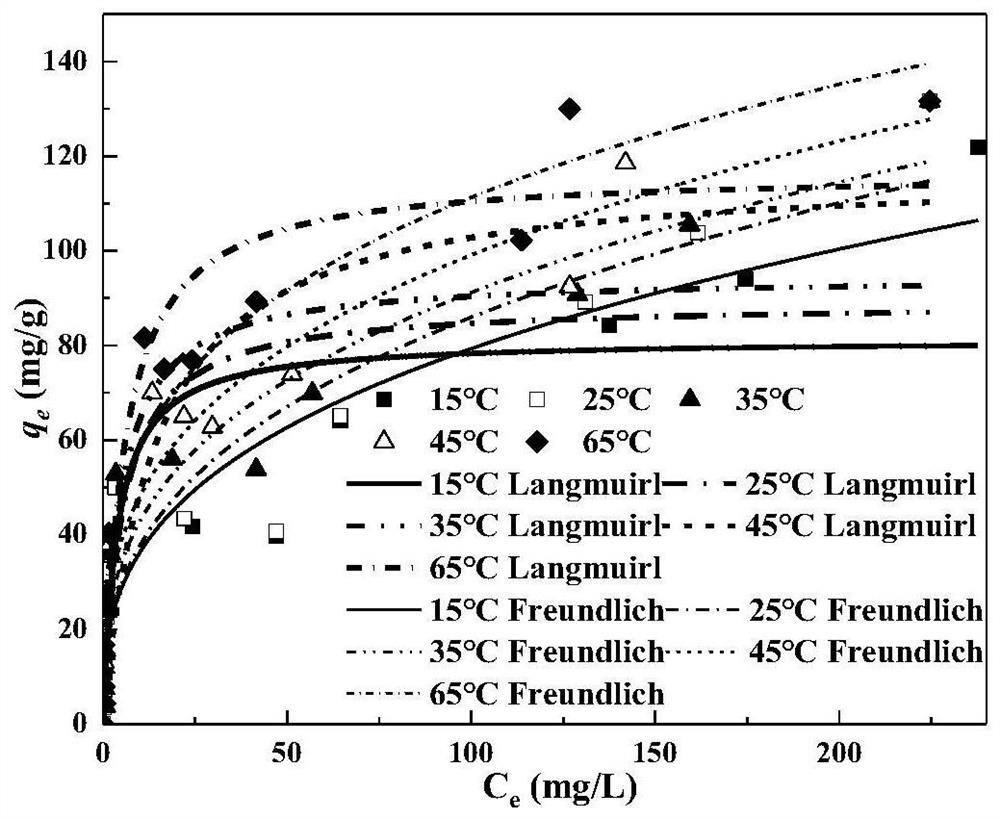

[0025] Put 20 mg of BC-La-BC into a polyethylene centrifuge tube filled with 15 mL of phosphate solution (pH=3), and set the initial phosphorus concentration to 5, 10, 15, 20, 30, 50, 70, 80, 100 , 150, 250, 300 and 400 mg / L, adjust the pH to 3.0, shake the above mixture at 15, 25, 35, 45 and 65 °C for 24 hours to reach adsorption equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com