Rubber affinity-type aqueous polyurethane adhesive, and preparation method thereof

A water-based polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems that cannot be omitted, poor persistence, unusable, etc., to increase polarity and reduce production Cycle, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

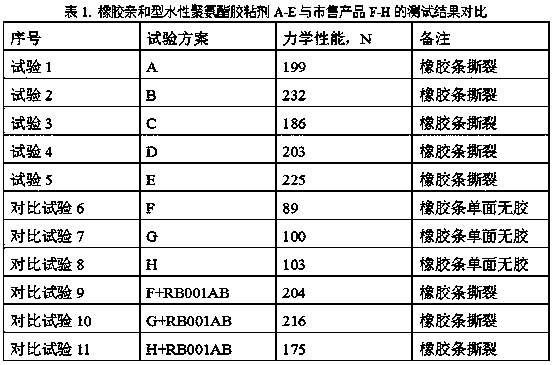

Image

Examples

Embodiment 1

[0029] (1) Add 1 mol of polyoxyethylene ether-50 (PEG-50), 0.02 mol of 2,2-dimethylol propionic acid and 0.18 mol of n-octanol into the reaction kettle, raise the temperature to 120°C, and remove moisture by vacuuming , until the weight ratio of water is 0.03%; cool down to 45°C, add 1.11 mol of hexamethylene diisocyanate to the system, and raise the temperature to 100°C, react for 0.5 hours and cool down to 40°C to obtain an isocyanate prepolymer;

[0030] (2) Take 0.18 mol 1,3-dibromo-1,3,5-triazine-2,4,6-trione, add 1.8 mol butanone to dissolve, slowly add 0.18 mol sodium methoxide, and stir at 25°C for 2 hours After filtering, collect the filtrate;

[0031] (3) Add 40 mol butanone to the isocyanate prepolymer in step (1) to reduce the viscosity of the system, add the filtrate obtained in step (2), heat up to 75°C, react for 1 hour and cool down to 30-40°C;

[0032] (4) After slowly adding 3 kg of water dropwise, recover the butanone in the system by vacuum distillation. T...

Embodiment 2

[0035] (1) Add 1 mol of polyoxypropylene ether-30 (PPG-30), 0.1 mol of 2,2-dimethylolpropionic acid and 0.26 mol of lauryl alcohol into the reaction kettle, raise the temperature to 150°C, and remove the water by vacuuming, until the weight ratio of water is 0.07%; cool down to 40°C, add 1.23 mol 2,4-toluene diisocyanate to the system, and raise the temperature to 60°C, react for 8 hours and cool down to 40°C to obtain an isocyanate prepolymer;

[0036] (2) Take 0.15 mol 1,3-dibromo-1,3,5-triazine-2,4,6-trione, add 1.5 mol butanone to dissolve, slowly add 0.15 mol sodium ethoxide, and stir at 25°C for 2 hours After filtering, collect the filtrate;

[0037](3) Add 30 mol butanone to the isocyanate prepolymer in step (1) to reduce the viscosity of the system, add the filtrate obtained in step (2), and then add 0.11 mol polyoxypropylene ether-30 (PPG-30), Raise the temperature to 50°C, and cool down to 30-40°C after reacting for 5 hours;

[0038] (4) After slowly adding 2.5 kg ...

Embodiment 3

[0041] (1) Add 1 mol polyoxyethylene-20-polyoxypropylene-20 copolymer (PEG-20-co-PPG-20), 0.08 mol 2,2-dimethylolbutyric acid and 0.14 mol n-decyl alcohol In the reaction kettle, heat up to 150°C, vacuumize to remove water until the weight ratio of water is 0.09%; cool down to 50°C, add 1.15 mol of diphenylmethane diisocyanate to the system, and raise the temperature to 70°C, react for 3 hours and then cool down to 40°C to obtain isocyanate prepolymer;

[0042] (2) Take 0.05 mol of 1,3-dibromo-1,3,5-triazine-2,4,6-trione, add 5 mol of butanone to dissolve, slowly add 0.05 mol of sodium ethoxide, and stir at 30°C for 1 hour After filtering, collect the filtrate;

[0043] (3) Add 35 mol butanone to the isocyanate prepolymer in step (1) to reduce the viscosity of the system, add the filtrate obtained in step (2), and then add 0.09 mol polyoxyethylene-20-polyoxypropylene-20 to copolymerize (PEG-20-co-PPG-20), heat up to 65°C, react for 4 hours and cool down to 30-40°C;

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com