Preparation method of modified organic montmorillonite/nylon 6 composite

A technology of organic montmorillonite and composite materials, which is applied in the field of preparation of modified organic montmorillonite/nylon 6 composite materials, can solve the problems of complex process, easy deformation, small elastic modulus, etc., and achieve improved interaction and affinity Strong, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

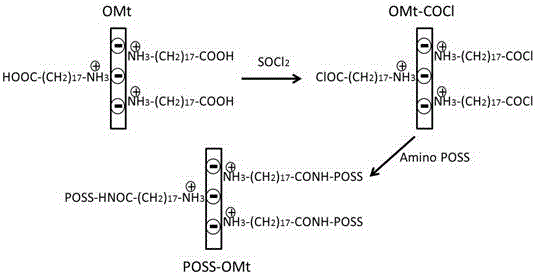

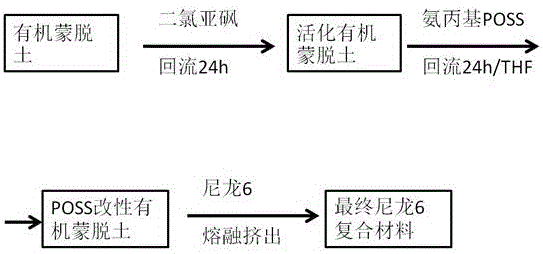

[0019] Using aminopropyl POSS to modify organic montmorillonite modified by 18 carboxyammonium bromide, the reaction principle is as follows figure 1 shown. First, add 300 mg of organic montmorillonite, magnetons and about 150 ml of thionyl chloride to a 250 ml one-necked flask respectively, and stir and reflux the reaction at 60° C. for 20 hours. It can be seen that before the reaction, it was a light yellow-brown turbid liquid, and after 24 hours, it was a black turbid liquid. The activated organic montmorillonite was obtained by suction filtration with a Buchner funnel. Then, the activated organic montmorillonite obtained by suction filtration was added into a 250ml one-necked flask, and then 300mg of aminopropyl POSS, magnetons and about 150ml of tetrahydrofuran were added, and the reaction was stirred and refluxed at 60°C for 20 hours. The gray powdery solid was obtained by suction filtration, put into a vacuum drying oven, dried in vacuum at 50 degrees Celsius for 24 h...

Embodiment 2

[0021] Using aminopropyl POSS to modify organic montmorillonite modified by 18 carboxyammonium bromide, the reaction principle is as follows figure 1 shown. Firstly, 1.5 g of organic montmorillonite, magneton and about 150 ml of thionyl chloride were respectively added into a 250 ml one-necked flask, and the reaction was stirred and refluxed at 90° C. for 30 hours. It can be seen that before the reaction, it was a light yellow-brown turbid liquid, and after 24 hours, it was a black turbid liquid. The activated organic montmorillonite was obtained by suction filtration with a Buchner funnel. Then, the activated organic montmorillonite obtained by suction filtration was added into a 250ml one-necked flask, and then 3g of aminopropyl POSS, magnetons and about 150ml of tetrahydrofuran were added, and the reaction was stirred and refluxed at 90°C for 30 hours. The gray powdery solid was obtained by suction filtration, put into a vacuum drying oven, dried under vacuum at 50°C for ...

Embodiment 3

[0023] Using aminopropyl POSS to modify organic montmorillonite modified by 18 carboxyammonium bromide, the reaction principle is as follows figure 1 shown. Firstly, 12 g of organic montmorillonite, magnetons and about 600 ml of thionyl chloride were respectively added into a 1-liter single-necked flask, and the reaction was stirred and refluxed at 75° C. for 24 hours. It can be seen that before the reaction, it was a light yellow-brown turbid liquid, and after 24 hours, it was a black turbid liquid. The activated organic montmorillonite was obtained by suction filtration with a Buchner funnel. Then, the activated organic montmorillonite obtained by suction filtration was added into a 1-liter single-necked flask, and then 24 g of aminopropyl POSS, magnetons and about 600 ml of tetrahydrofuran were added, and the reaction was stirred and refluxed at 75° C. for 24 hours. The gray powdery solid was obtained by suction filtration, put into a vacuum drying oven, dried in vacuum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com