Medium-frequency induction furnace

An induction electric furnace and intermediate frequency technology, which is applied in the field of intermediate frequency induction electric furnaces, can solve the problems of poor vacuuming effect, poor overall service ability of intermediate frequency induction electric furnaces, poor sealing effect of the furnace mouth of intermediate frequency induction electric furnaces and strong magnetic induction, etc., and achieves strong affinity and enhanced The sealing effect, the effect of enhancing the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

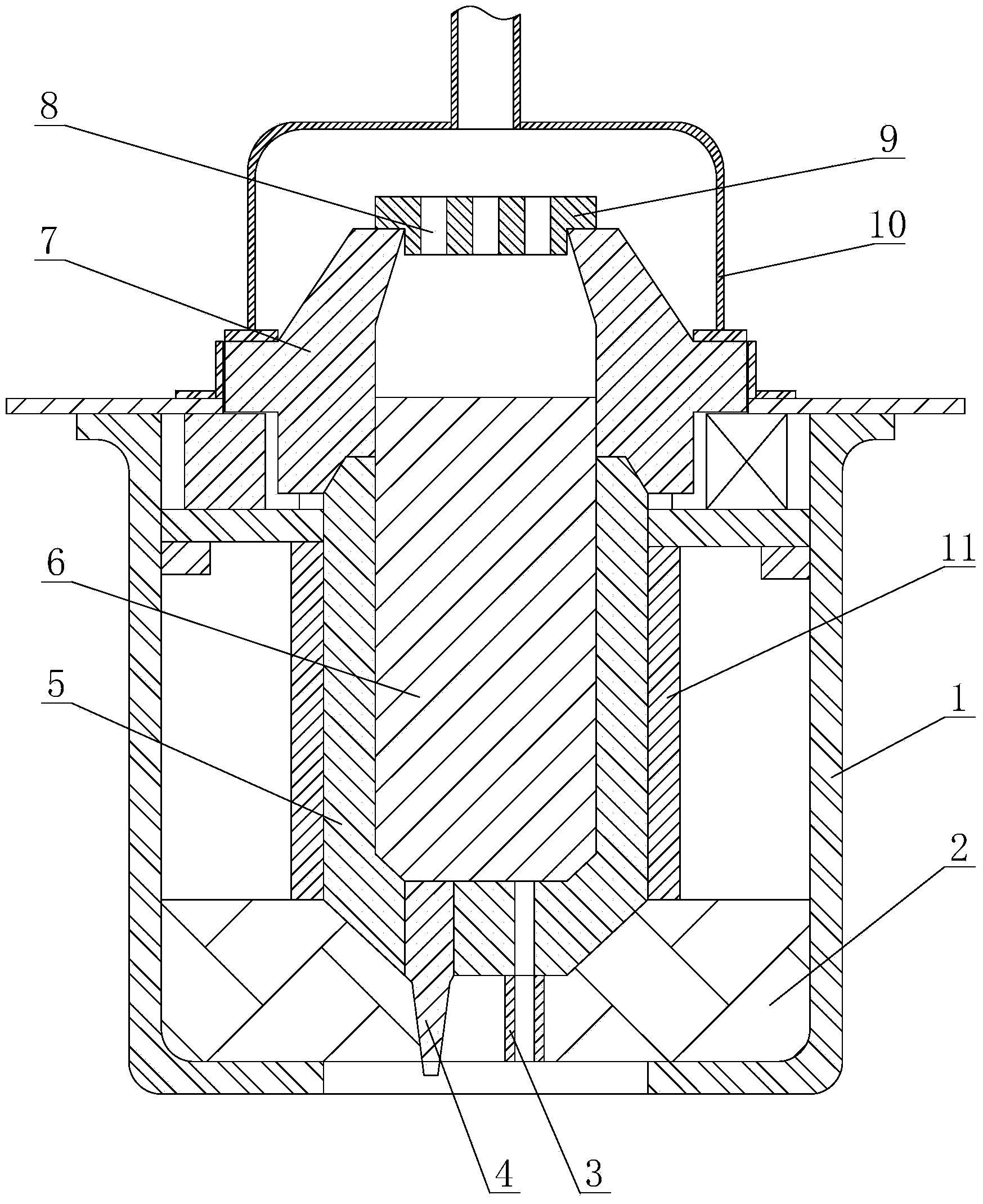

[0014] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of an intermediate frequency induction furnace according to the present invention; in this embodiment, an intermediate frequency induction furnace includes a furnace shell 1, a furnace bottom 2 and a furnace lining 5 arranged in the furnace shell 1, and on the outer wall of the furnace lining 5 An induction coil 11 is provided, the top of the induction coil 11 is provided with a yoke, the furnace lining 5 is made of aluminum-magnesium spinel material, the bottom end is provided with a ventilation brick 4, the bottom drain pipe 3, and the upper end is provided with a There is a closed ring 7, and the closed ring 7 is composed of a heat insulation ring, a water cooling ring, and a metal sealing ring. The metal sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com