Quartz sand grinding equipment capable of reducing loss of grinding disc and working method of quartz sand grinding equipment

A technology of quartz sand and grinding discs, which is applied in chemical instruments and methods, solid separation, sounding equipment, etc., can solve the problems of excessive sand body size, sharp edges and corners of sand bodies, sand jamming of grinding discs, etc., and achieve the goal of solving sand jamming, The effect of reducing the loss of grinding discs and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

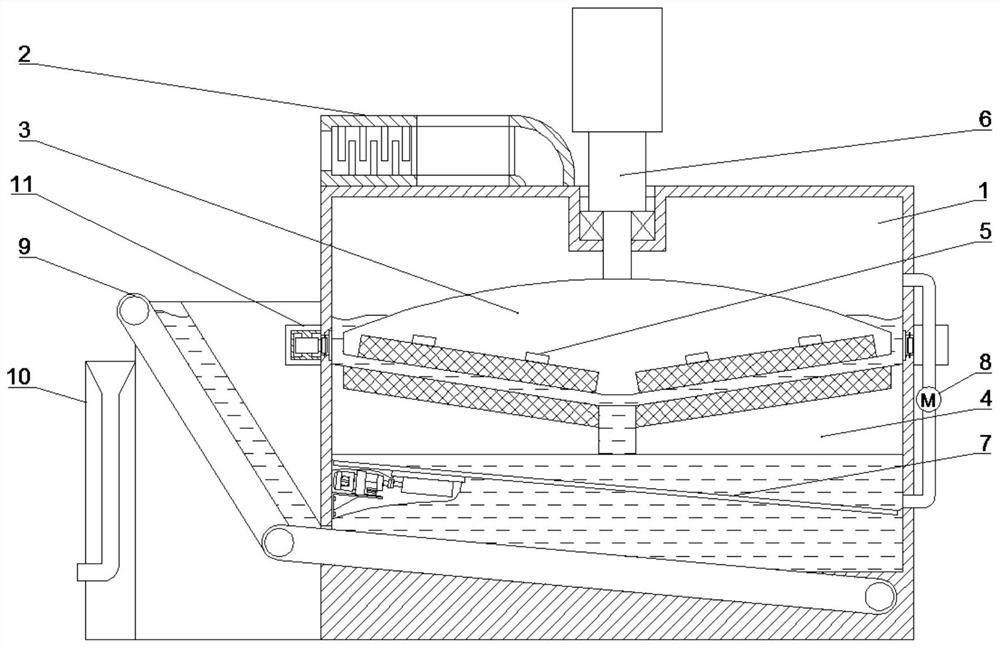

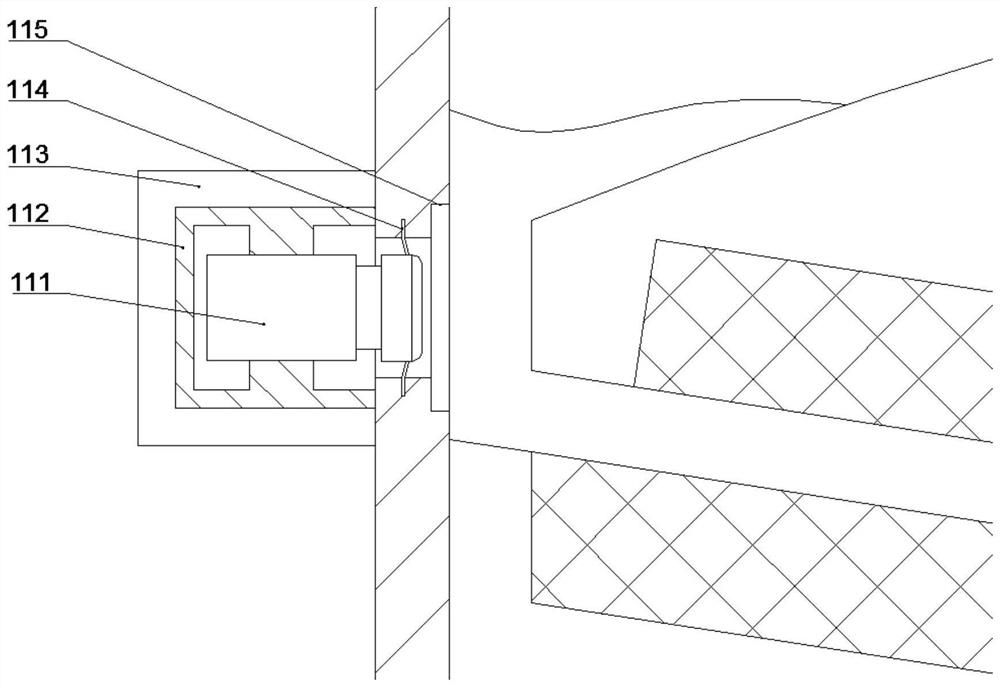

[0040] Such as Figure 1-3 The shown quartz sand grinding equipment for reducing the loss of grinding discs includes: a grinding bin 1, a crushed material bin 2, a main grinding disc 3, an auxiliary grinding disc 4, a pressure sensor 5 and an electromagnetic proportional gearbox 6. The top of the grinding bin 1 A broken material bin 2 is provided, the bottom of the broken material bin 2 is provided with a main millstone 3, the main millstone 3 is arranged in the grinding bin 1, and the bottom of the main millstone 3 is provided with an auxiliary millstone 4, and the auxiliary millstone 4 is connected with the The main millstone 3 cooperates; the main millstone 3 is provided with a pressure sensor 5, and the pressure sensor 5 is provided with a plurality, and the pressure sensor 5 is connected with an electromagnetic proportional gearbox 6, and the electromagnetic proportional gearbox 6 is arranged on Main grinding disc 3 input.

[0041] The auxiliary grinding disc 4 described...

Embodiment 2

[0054] Such as figure 1 The shown quartz sand grinding equipment for reducing the loss of grinding discs includes: a grinding bin 1, a crushed material bin 2, a main grinding disc 3, an auxiliary grinding disc 4, a pressure sensor 5 and an electromagnetic proportional gearbox 6. The top of the grinding bin 1 A broken material bin 2 is provided, the bottom of the broken material bin 2 is provided with a main millstone 3, the main millstone 3 is arranged in the grinding bin 1, and the bottom of the main millstone 3 is provided with an auxiliary millstone 4, and the auxiliary millstone 4 is connected with the The main millstone 3 cooperates; the main millstone 3 is provided with a pressure sensor 5, and the pressure sensor 5 is provided with a plurality, and the pressure sensor 5 is connected with an electromagnetic proportional gearbox 6, and the electromagnetic proportional gearbox 6 is arranged on Main grinding disc 3 input.

[0055] The auxiliary grinding disc 4 described in...

Embodiment 3

[0059] Such as figure 1 with 2 The shown quartz sand grinding equipment for reducing the loss of grinding discs includes: a grinding bin 1, a crushed material bin 2, a main grinding disc 3, an auxiliary grinding disc 4, a pressure sensor 5 and an electromagnetic proportional gearbox 6. The top of the grinding bin 1 A broken material bin 2 is provided, the bottom of the broken material bin 2 is provided with a main millstone 3, the main millstone 3 is arranged in the grinding bin 1, and the bottom of the main millstone 3 is provided with an auxiliary millstone 4, and the auxiliary millstone 4 is connected with the The main millstone 3 cooperates; the main millstone 3 is provided with a pressure sensor 5, and the pressure sensor 5 is provided with a plurality, and the pressure sensor 5 is connected with an electromagnetic proportional gearbox 6, and the electromagnetic proportional gearbox 6 is arranged on Main grinding disc 3 input.

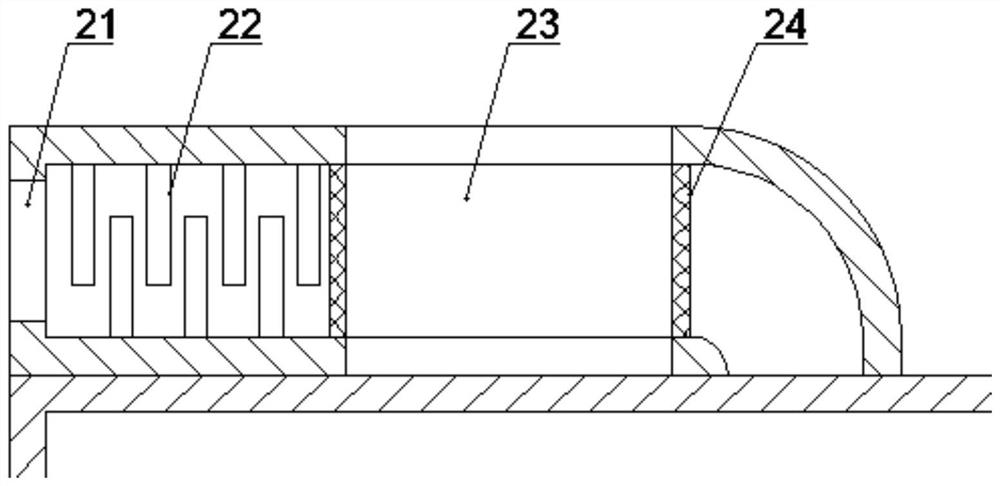

[0060] The crushed material bin 2 describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com