Guiding and guarding system

A technology of guides and rolling mills, applied in the direction of guiding/positioning/alignment devices, etc., can solve problems such as floating up and down, not meeting the requirements of continuous rolling and rolling processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

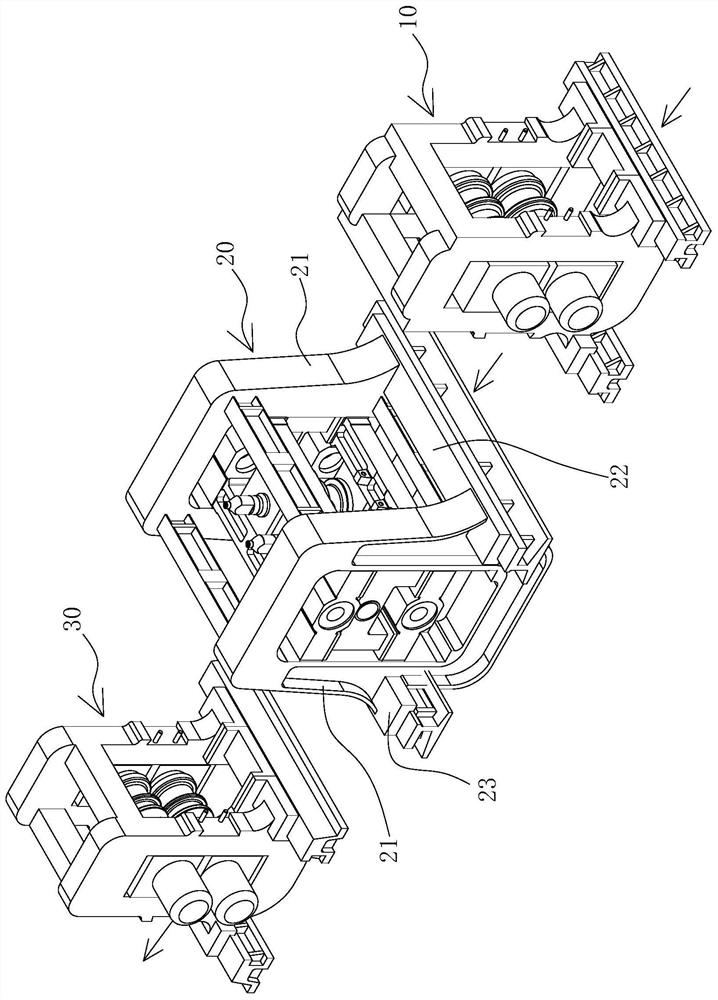

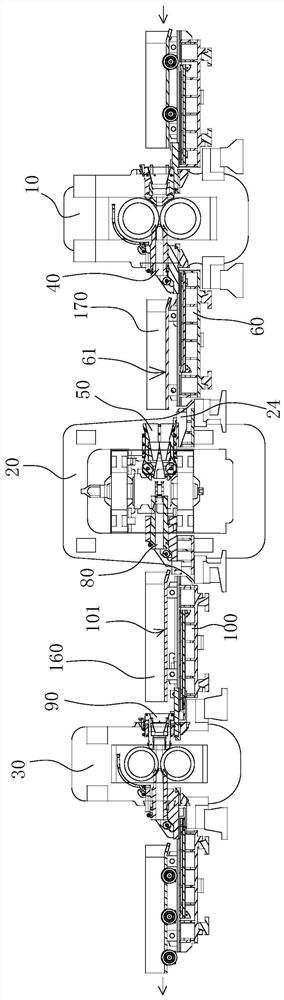

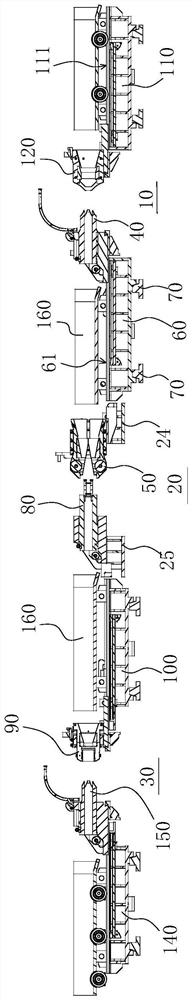

[0019] The guide system provided by the present invention is applicable to the continuous rolling system composed of the upper, middle and lower rolling mills 10, 20, 30, especially the diameter of the roll is up to 1m, and the billet to be rolled is 200mm*200mm or larger Bars with cross-sectional diameters of 75-350mm or even larger. Such as figure 1 , 2, there is a guide base between the upper and middle rolling mills 10 and 20 or the middle and lower rolling mills 20 and 30, and the extension direction of the track on the guide base is parallel to the rolling direction of the rolled piece. The direction of the arrow in the figure is The rolling direction of the rolled piece, the entrance guides and exit guides of the upper and middle rolling mills 10, 20 or the middle and lower rolling mills 20, 30 are displaced along the direction defined by the track and locked by the locking mechanism in the upper, middle and downstream Location at the entrance or exit of the rolling mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com