Steel wire machining equipment capable of resisting metal fatigue

A processing equipment and anti-metal technology, which is applied in the field of anti-metal fatigue steel wire processing equipment, can solve problems such as lifting drop, steel wire coil drop, and high risk factor, so as to increase feeding efficiency, increase safety, and avoid falling fall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

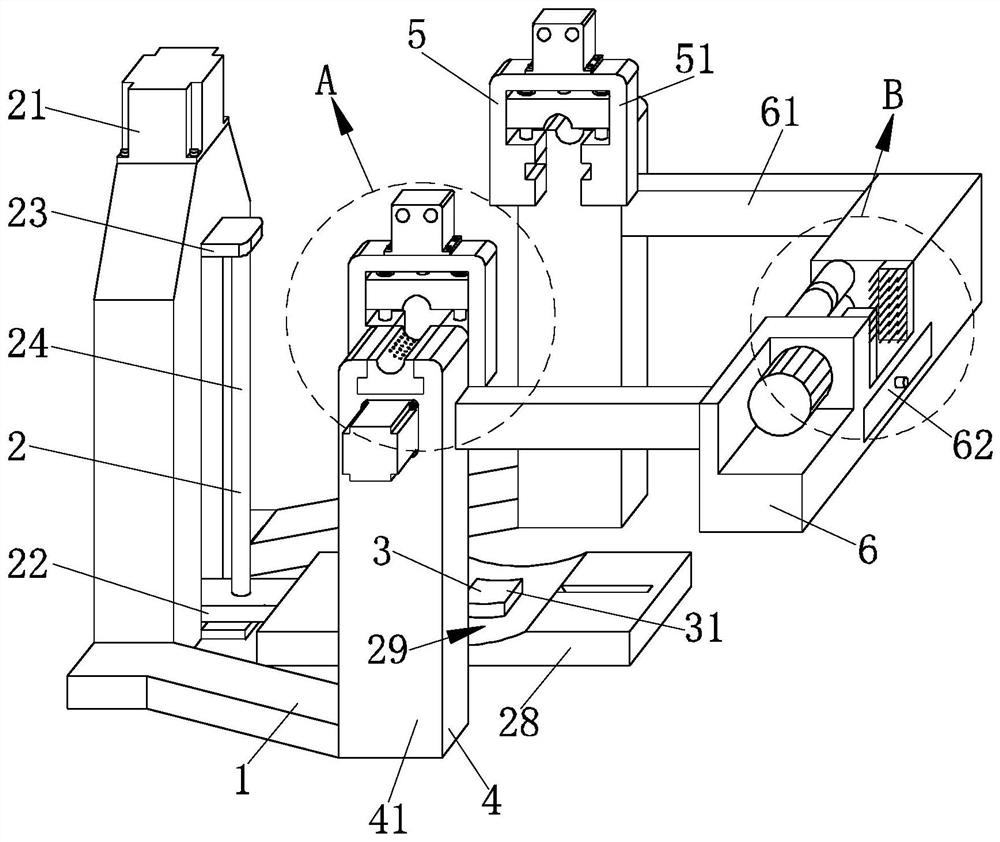

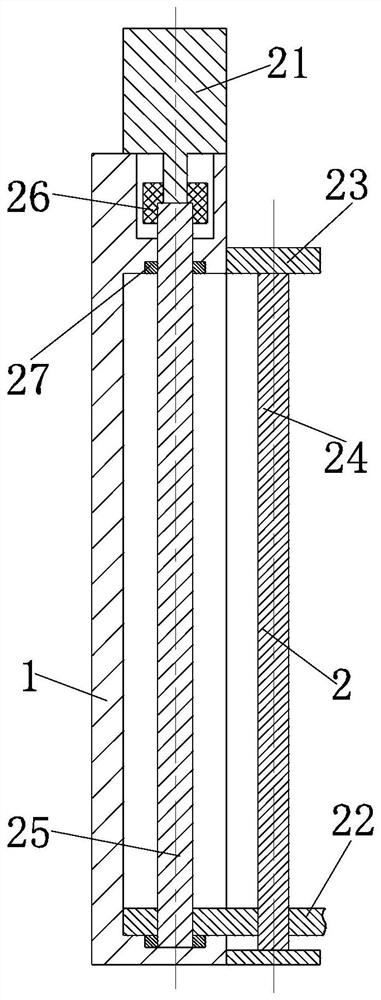

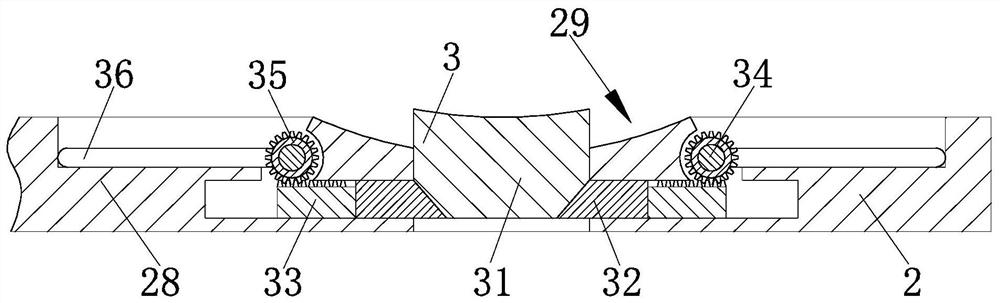

[0025] Such as Figure 1-Figure 7 As shown, a kind of anti-metal fatigue steel wire processing equipment according to the present invention includes a support 1, a feeding structure 2, an anti-drop structure 3, a placing structure 4, a pressing structure 5 and a straightening structure 6, and is used for starting One end of the support 1 that supports and installs other components is installed and can automatically lift the coiled steel wire coils to the feeding structure 2 on the discharge rack; When carrying out the described anti-falling structure 3 that the steel wire coil is limited and fixed, a symmetrical relationship is installed at the two ends of the support 1 respectively, and a steel wire coil that can be lifted can be placed and rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com