Processing equipment for paper-plastic composite bag production

A paper-plastic composite bag and processing equipment technology, applied in papermaking, bag-making operations, paper/cardboard containers, etc., can solve the problems of slow drying of glue, affecting the final forming effect of composite tapes, etc., to improve processing efficiency and enhance functions. High performance and convenience, uniform and effective glue bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

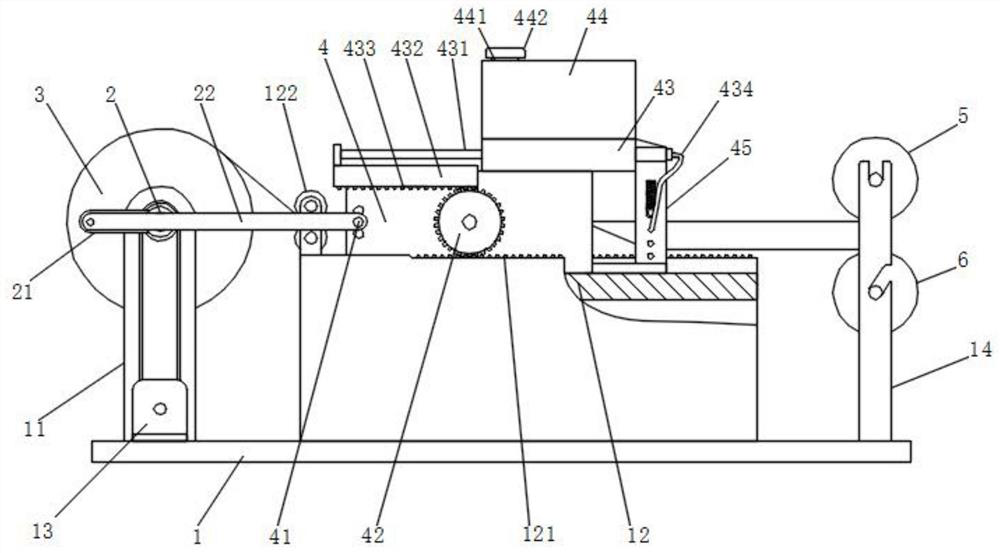

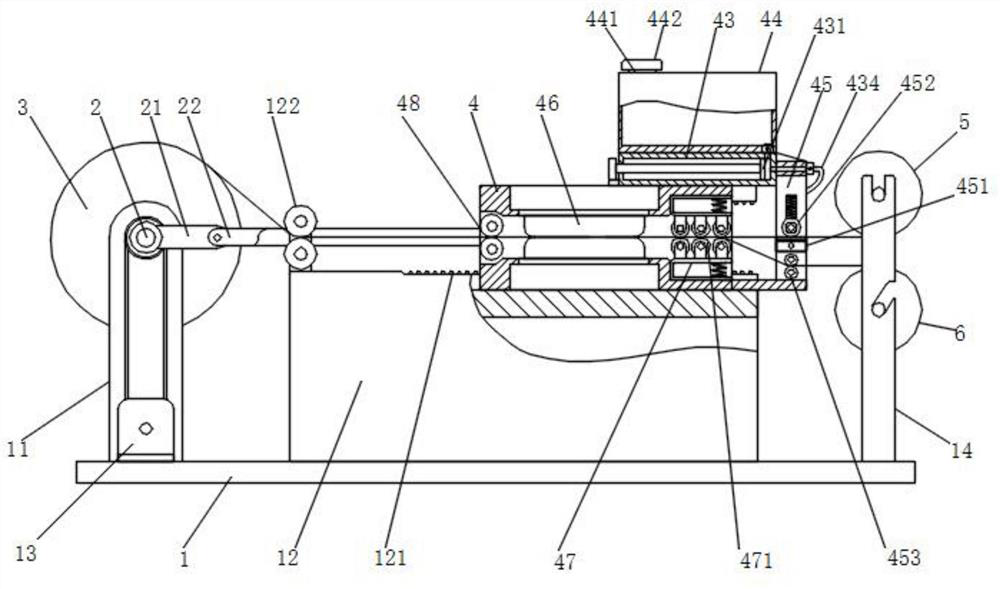

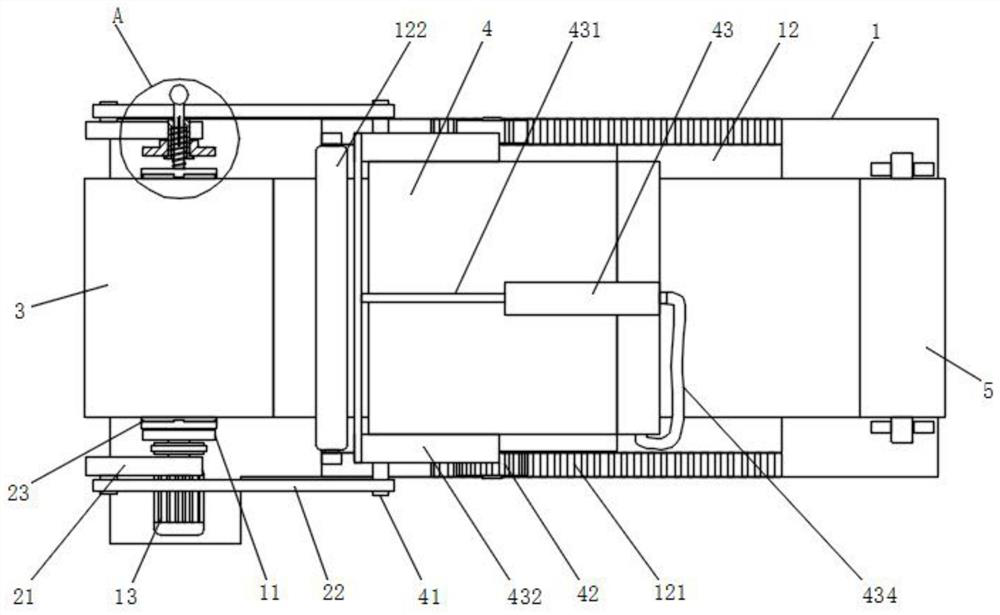

[0027] The present invention provides such as Figure 1-5The shown processing equipment for the production of a paper-plastic composite bag comprises a base 1, two first brackets 11 are fixed at one end of the top of the base 1, and connecting shafts 2 are installed on the tops of the first brackets 11 for rotation, A winding roller 3 is installed between the two connecting shafts 2, and a driving motor 13 is fixedly installed on the bottom of one of the first brackets 11, and the driving motor 13 is connected to one of the connecting shafts 2 through a belt transmission assembly. The outer end of the connecting shaft 2 is fixedly equipped with a rocker 21, and the outer side of the rocking rod 21 away from the end of the connecting shaft 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com