Brake control valve and commercial vehicle high-comfort hydraulic brake system

A braking control and braking system technology, applied in the direction of braking transmission, brakes, vehicle components, etc., can solve the problems of poor comfort experience, cab shaking, large cab pitch angle, etc., to improve the effect efficiency ratio , Improve the effect of wear conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

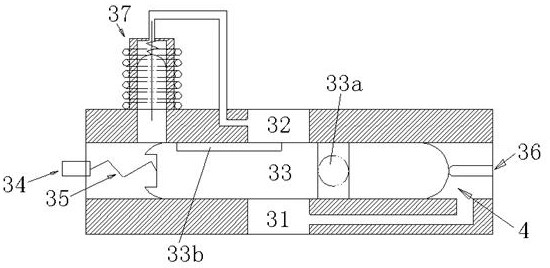

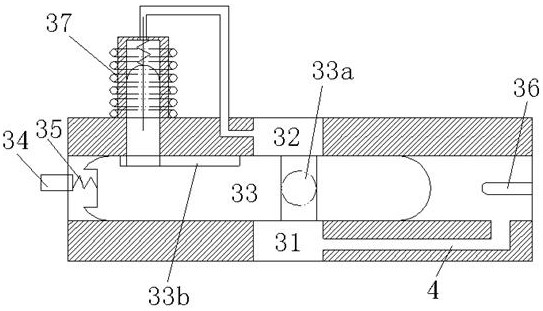

[0040] This embodiment relates to a brake control valve installed in a dual circuit hydraulic brake system, such as Figure 1-3 shown. The control valve 3 has an input port 31 communicated with the master cylinder end of the front brake circuit and an output port 32 communicated with the brake end of the front brake circuit; between the input port 31 and the output port 32 A spool 33 is installed elastically in the valve chamber between them; one end of the spool 33 is a preload adjustment end 33-1, and the other end is a stop end 33-2, and the preload adjustment end is provided with an adjustment screw 34 and A return spring 33, the adjustment screw 34 is installed on the valve body in a spiral manner, one end of the return spring 33 is connected with the adjustment screw 34, and the other end is connected with the end of the valve core 33, by adjusting the adjustment screw 34 The screw degree can adjust the compression amount of the return spring 33, so that the valve core ...

Embodiment 2

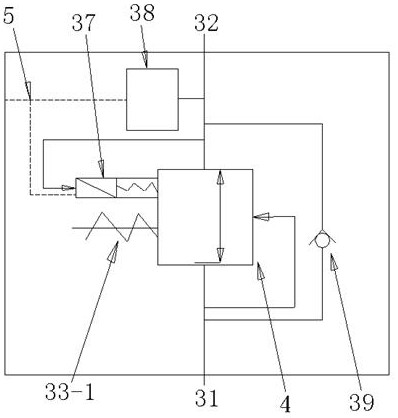

[0046] This embodiment relates to a commercial vehicle high-comfort hydraulic brake system, such as Figure 4 shown. The braking system is mainly used to solve the following technical problems:

[0047] 1. When the hydraulic brake model is performing conventional braking, the response rate and braking strength of the front axle disc brake will be significantly ahead of the rear axle, which will make the pitch angle of the cab larger during braking and make the driver more comfortable. poor experience;

[0048] 2. The response of the front axle disc brake is obviously ahead of that of the rear axle, and the area of the disc brake lining is smaller, so that the front axle disc brake lining wears significantly during conventional braking, and the replacement is frequent.

[0049] A high-comfort hydraulic brake system for a commercial vehicle in this embodiment includes: a master cylinder 2 controlled by a brake pedal 1, a disc brake configured on the front wheel of the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com