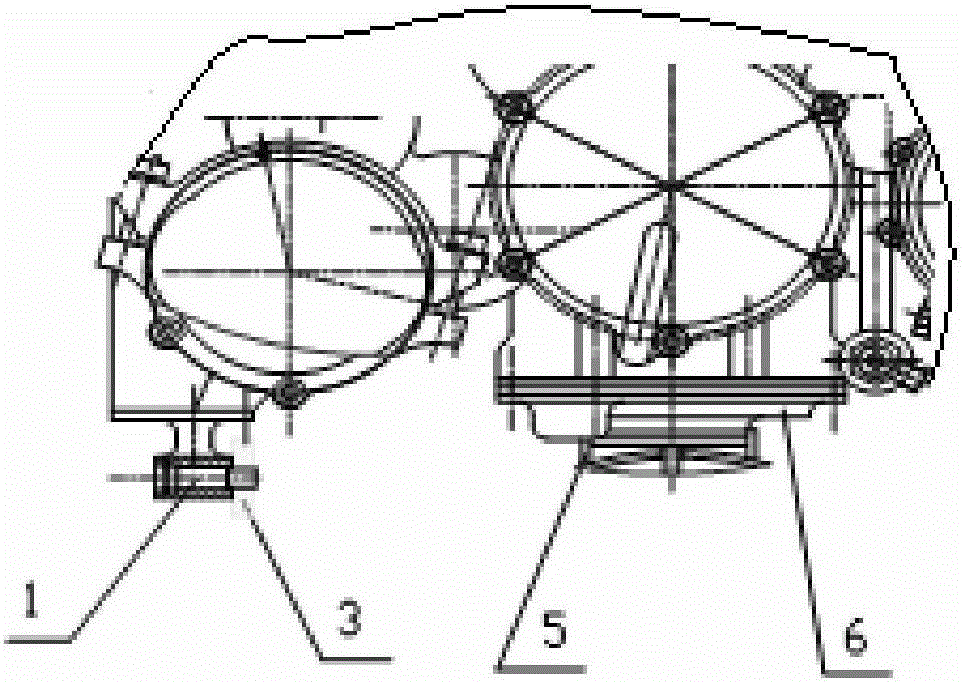

Repair method for dimension recovery of transfer lining of accessory drive gearbox

A size restoration and accessory transmission technology, which is applied to transmission boxes, transmission parts, belts/chains/gears, etc., can solve problems such as bushing wear, and achieve the effects of improving safety, reducing the probability of occurrence, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

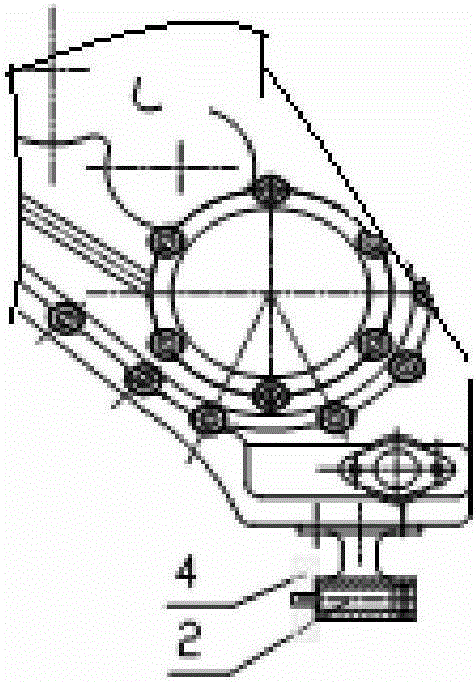

[0018] In the specific implementation process, with the continuous increase of the service life of the parts, the wear failure of the lower bearing bush of a certain series of accessory drive gearboxes has intensified, and the failure of joint surface wear and leakage of lubricating oil has occurred continuously, endangering the safety of use. In order to solve the wear problem of the lower bearing bush, the thermal spraying process is used to spray nickel-aluminum coating on the worn part. The biggest feature of the present invention is that the larger size can be recovered and grown at the worn parts through the spraying process, and the coating can be guaranteed to be consistent with the wear parts. For the bonding force of the substrate, the thermal spraying in the past is a targeted coating and plating, but the size of the plating used to restore the size is not enough to repair the bushing.

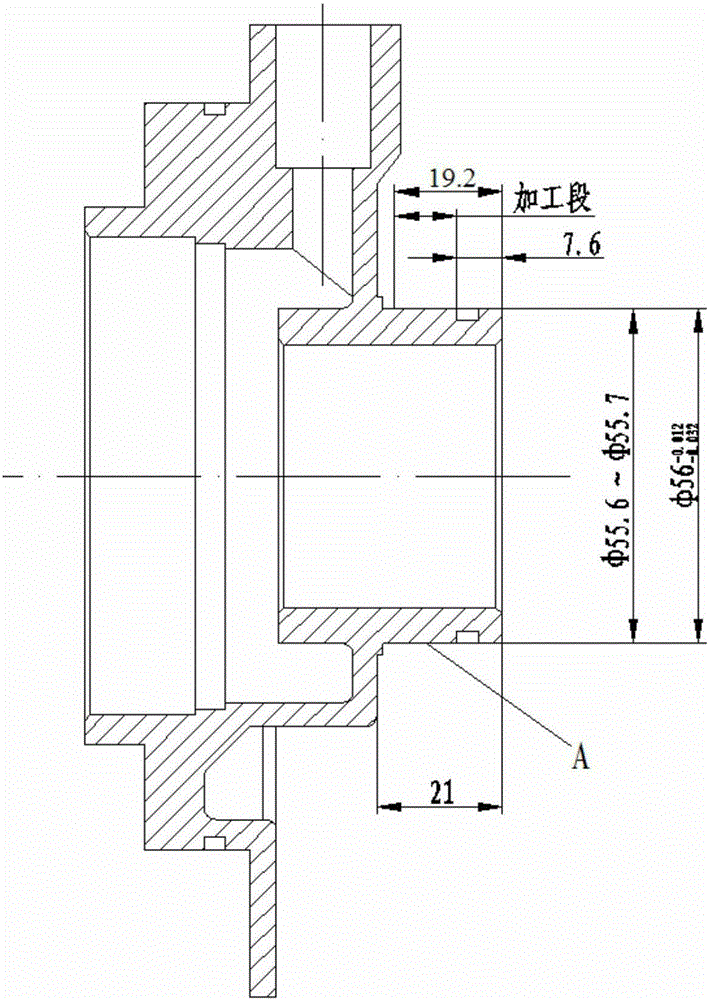

[0019] Such as figure 2 As shown, the supplementary processing size requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com