Accidental falling speed reduction structure for mine hoist

A mine hoist and deceleration structure technology, which is applied to mine hoisting equipment, elevators, transportation and packaging, etc., can solve the problems of insufficient safety and effectiveness, and achieve the effect of reducing risks and good deceleration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

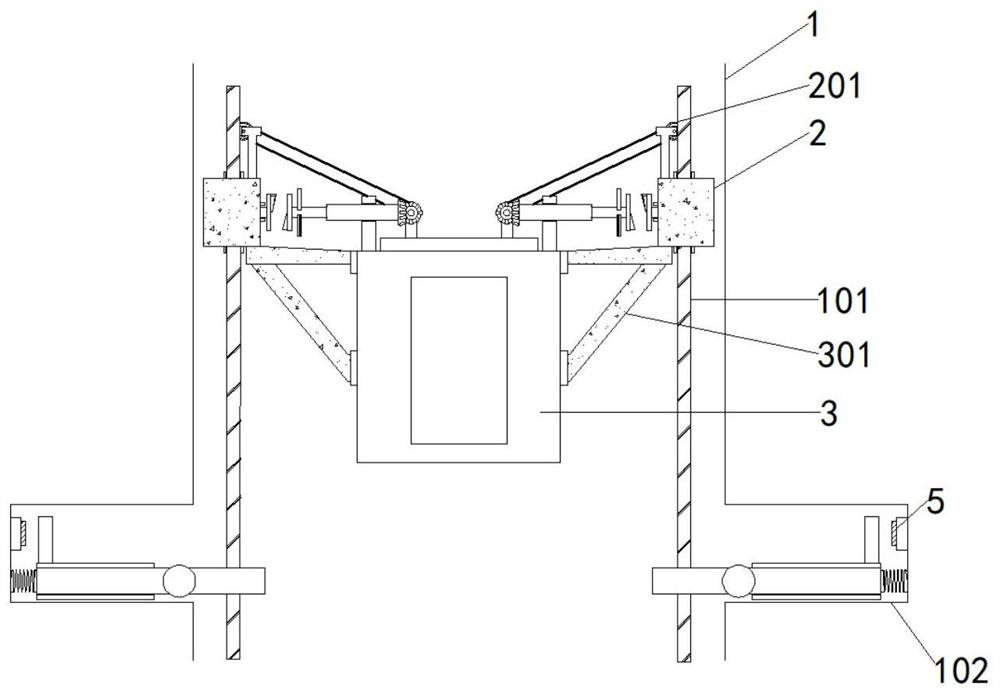

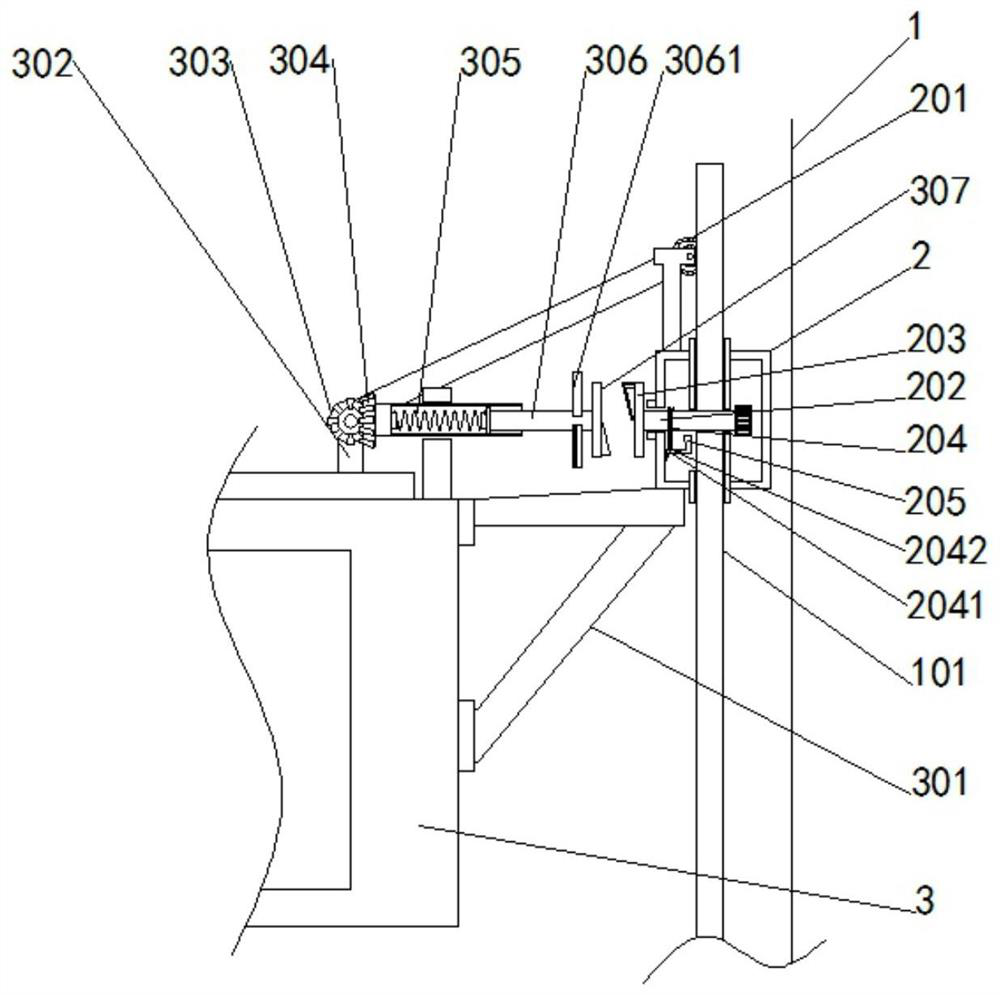

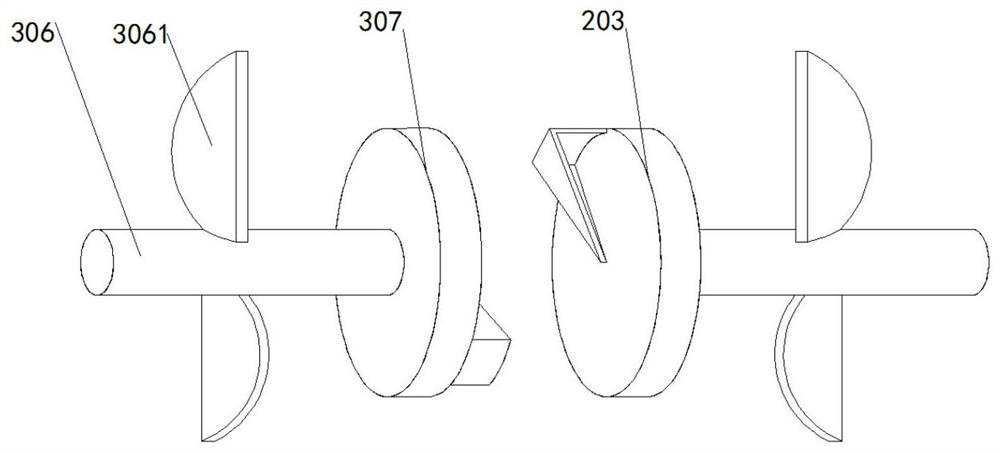

[0028] as attached figure 1 To attach Figure 9 Shown: an accidental fall deceleration structure for a mine hoist. The accidental fall deceleration structure for a mine hoist includes a mine 1 and a hoist 3. The mine 1 is equipped with a fall detection mechanism and a brake mechanism. Both sides of the inner wall of the mine 1 are Guide rails 101 are fixedly installed longitudinally, the hoist 3 is arranged between two sets of guide rails 101, support frames 301 are fixedly installed on both sides of the hoist 3, and the casing 2 is fixedly installed above the support frame 301, and the connection between the casing 2 and the guide rails 101 The upper parts of the two shells 2 are rotatably connected to the gear 201 through the bracket, and the guide rail 101 is provided with a tooth groove, and the gear 201 meshes with the tooth groove.

[0029] as attached figure 1 , 2 , shown in 6 and 7: the fall detection mechanism includes bevel gear one 303, bevel gear two 304, hollow...

Embodiment 2

[0035] Such as figure 1 , 5 As shown: a groove 102 is arranged inside the mine shaft 1 .

[0036] The present invention also includes a signal-triggered deceleration mechanism. The signal-triggered deceleration mechanism is located in the groove 102. The signal-triggered deceleration mechanism includes a signal transmitter, a signal receiver, and a deceleration mechanism. The deceleration mechanism includes an electromagnet 5, a chute 4, Sliding plate 401, compression spring 402, iron plate 403, electromagnet 5 are installed on the side of the groove 102 inner wall away from the mine, the bottom of sliding plate 401 is provided with a slider, and the slider is equipped with a chute 4 and is arranged at the bottom of the groove 102 On the wall, an iron plate 403 is fixedly installed on the top of the sliding plate 401, and the end of the sliding plate 401 away from the mine is connected to the inner wall of the groove 102 through a compression spring 402, and the signal transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com