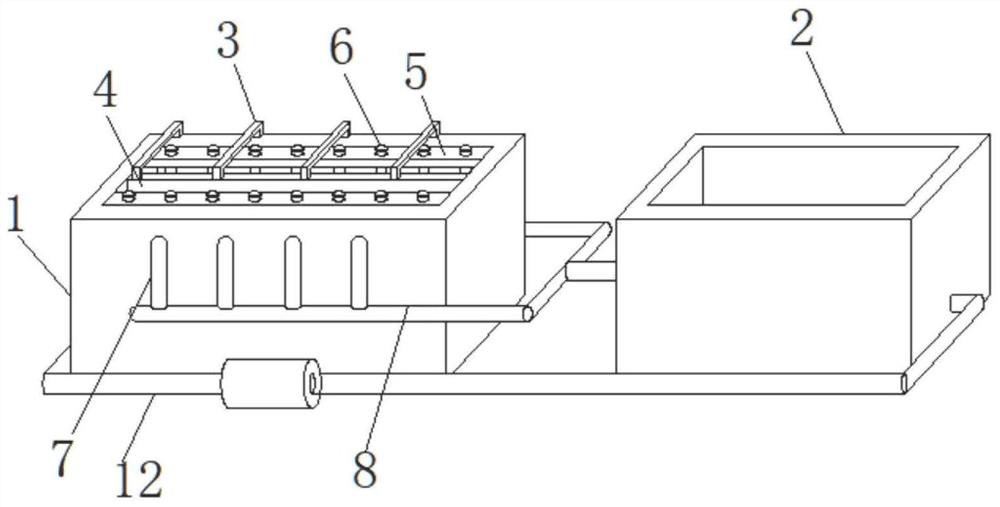

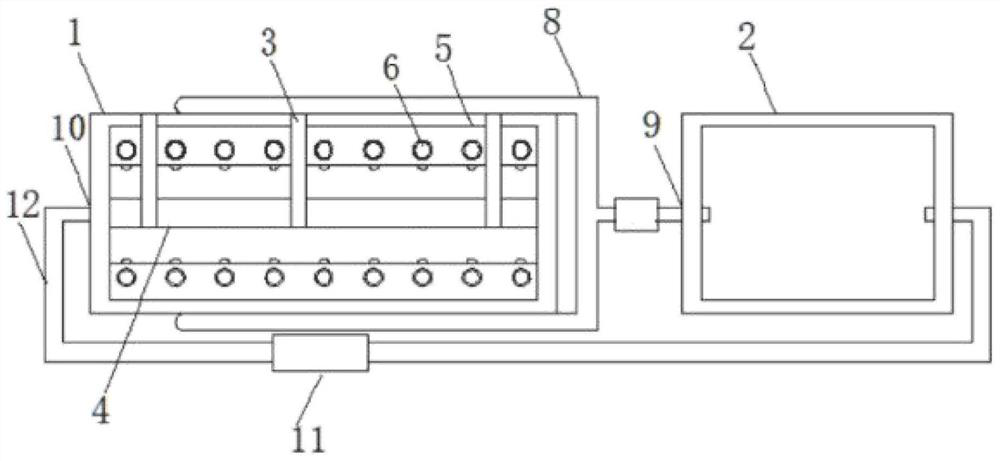

Application of ferric iron copper dissolving technology to vertical consecutive plating line and device of ferric iron copper dissolving technology

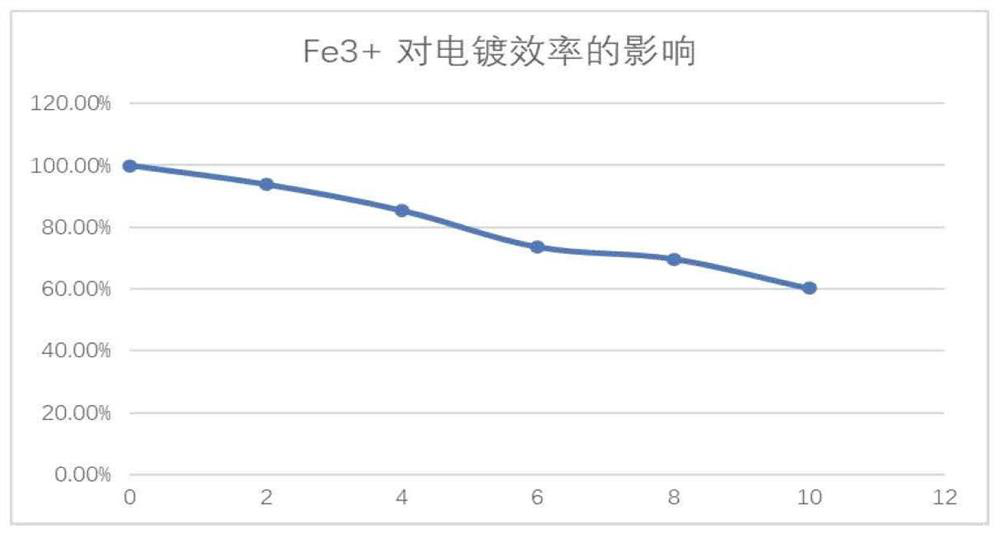

A vertical continuous electroplating, ferric iron technology, applied in electrical components, electrolysis process, electrolysis components, etc., can solve the problems of slow dissolution of copper oxide powder, no way to automate, environmental pollution, etc., to improve equipment utilization, improve electroplating Uniformity, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1

[0035] The trivalent iron copper tank and VCP electroplating groove are combined, and the VCP electroplating groove is installed with DC power supply: Cu2 +: 50g / L (200g / l CusO4 · 5H2O); H2SO4: 40G / L; CL-: 70PPM (0.175 ML / L 36.5% hydrochloric acid); total iron 30g / L; Fe3 +: 2.5g / L; special bracket electroplated additive, temperature control 28 ° C to 35 ° C, current density 2.5ASD, electroplated 25 um thickness, blind hole (4 mil width / 3mil Depth, DIMPLE <4UM, electroplating efficiency 91.2%. IC carrier graphics electroplating, 2.5ASD, uniform line, square, electroplating efficiency 90.9%.

Example Embodiment

[0036] Example 2

[0037]The trivalent iron copper tank and the VCP electroplating groove are combined, and the VCP plating tank is installed by the pulse power supply, and the electrolyte: Cu2 +: 40g / L (160g / L CusO4 · 5H2O); H2SO4: 60G / L; CL-: 70PPM (0.175 ML / L 36.5% hydrochloric acid); total iron 30g / L; Fe3 +: 2.5g / L; special bracket electroplated additive, temperature control 28 ° C to 35 ° C, effective current density 2.5ASD, electroplated 20 um thickness, blind hole (4 mil width / 3mil Depth, DIMPLE <2UM, blind hole (3 mil width / 2mildepth), DIMPLE <2UM, electroplating efficiency 91.3%. IC carrier graphics electroplating, fill hole, plate thickness 150 um, aperture 75 um, 2.5ASD, wire thickness, square, through hole DIMPLE <2UM, no porce hole core, electroplating efficiency 91.5%. Practical test found that the higher the acid concentration, the better the electroplating uniformity, and the waveform selection of the pulse also affects the uniformity of the graphic...

Example Embodiment

[0038] Example 3

[0039] The trivalent iron copper tank and VCP electroplating groove are used in thick plate PCB electroplating, VCP plating tank mounting pulse power supply, configuring electrolyte: Cu2 +: 20g / L (80g / L CusO4 · 5H2O); H2SO4: 240g / L; CL-: 70PPM (0.175 mL / l36.5% hydrochloric acid); total iron 30g / L; Fe3 +: 2.5g / L; special thick plate electroplated additive, temperature control 28 ° C to 35 ° C, effective current density 2.0ASD, electroplated 25um The thickness, the thickness of 120 mil, the via hole diameter 8 mil, the pore, the most thin copper thickness of 24.6 um, the inertial ability is close to 100%, and the electroplating efficiency is 92.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com