Cloth lifting wheel reversing driving mechanism of rope-shaped washing machine

A driving mechanism, a technology for washing machines, applied in liquid/gas/vapor rope fabric processing, textile material processing, liquid/gas/vapor processing transmission devices, etc. The problem of high cost, to achieve the effect of simple structure, use of upper space, and sensitive sensing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

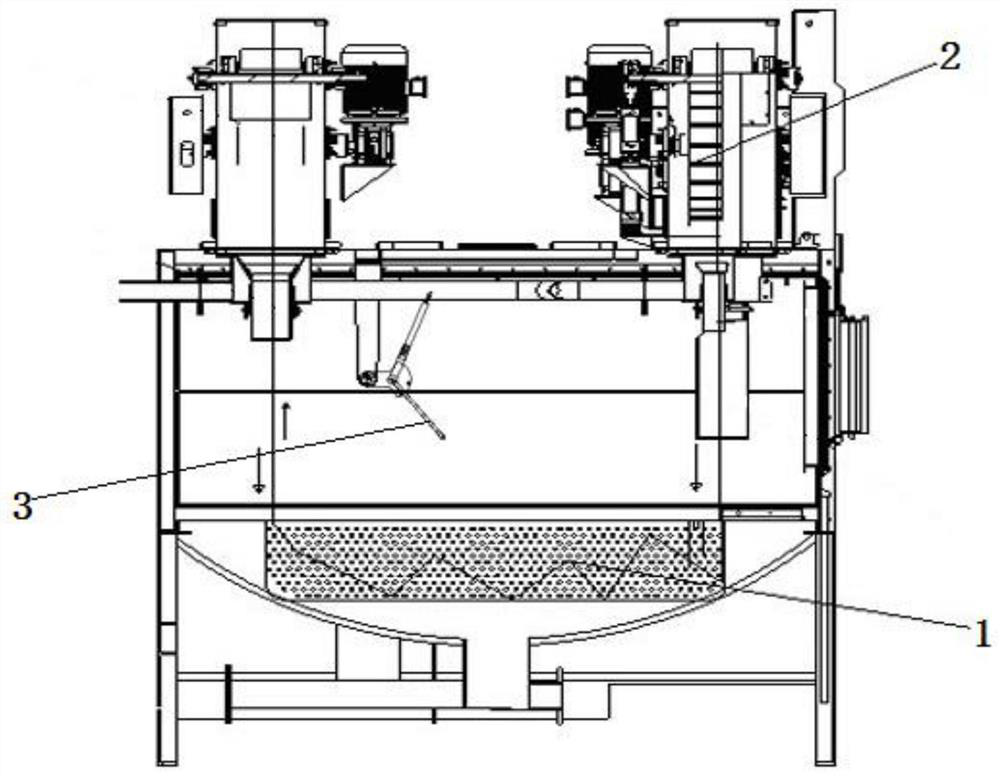

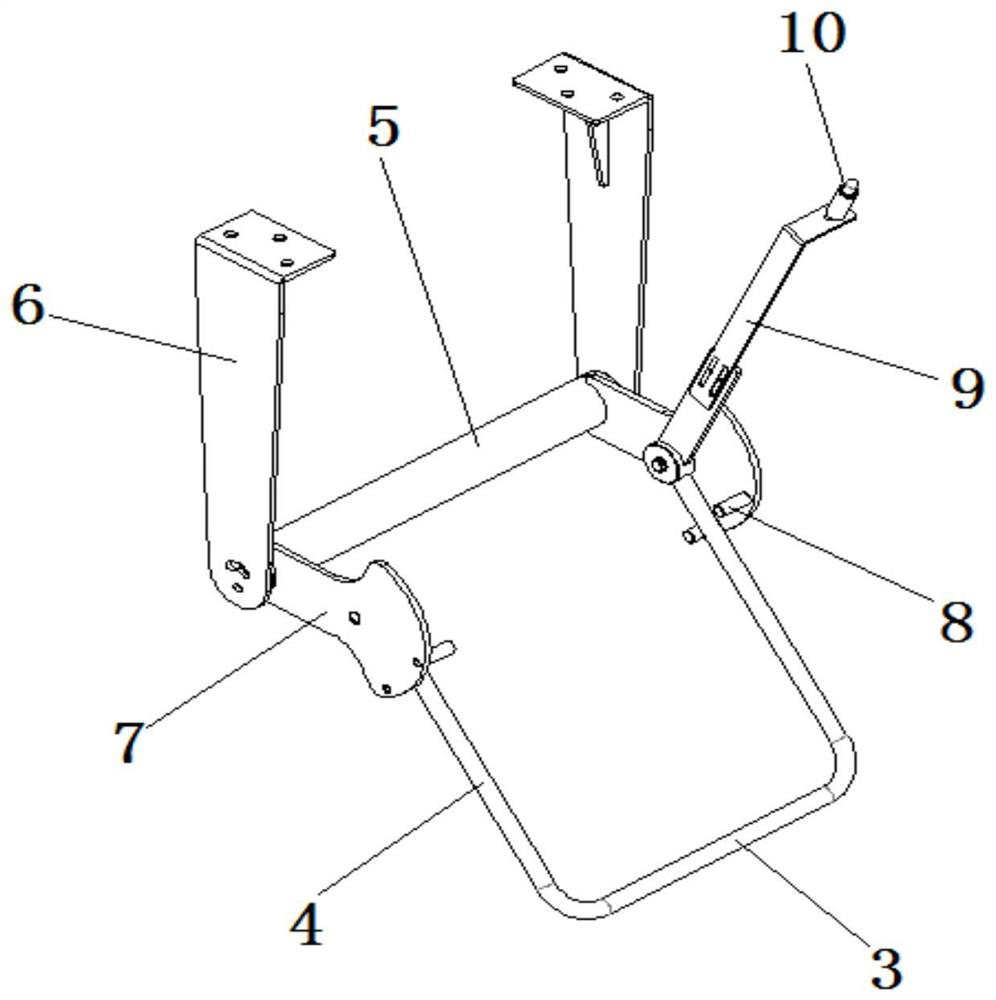

[0018] Embodiment: a cloth lifting wheel reversing drive mechanism of a rope washing machine, such as Figure 1-3 As shown, it includes two adjacent water tanks 1 and a cloth lifting wheel 2 arranged between the two water tanks. The cloth lifting wheel 2 can drive the fabric to be alternately transported between the two water tanks 1, so that the fabric can be alternately accumulated in the two water tanks 1 In this way, the fabrics are stacked in the water tank 1 for a long time, the washing time is prolonged, and the washing effect and washing efficiency are improved.

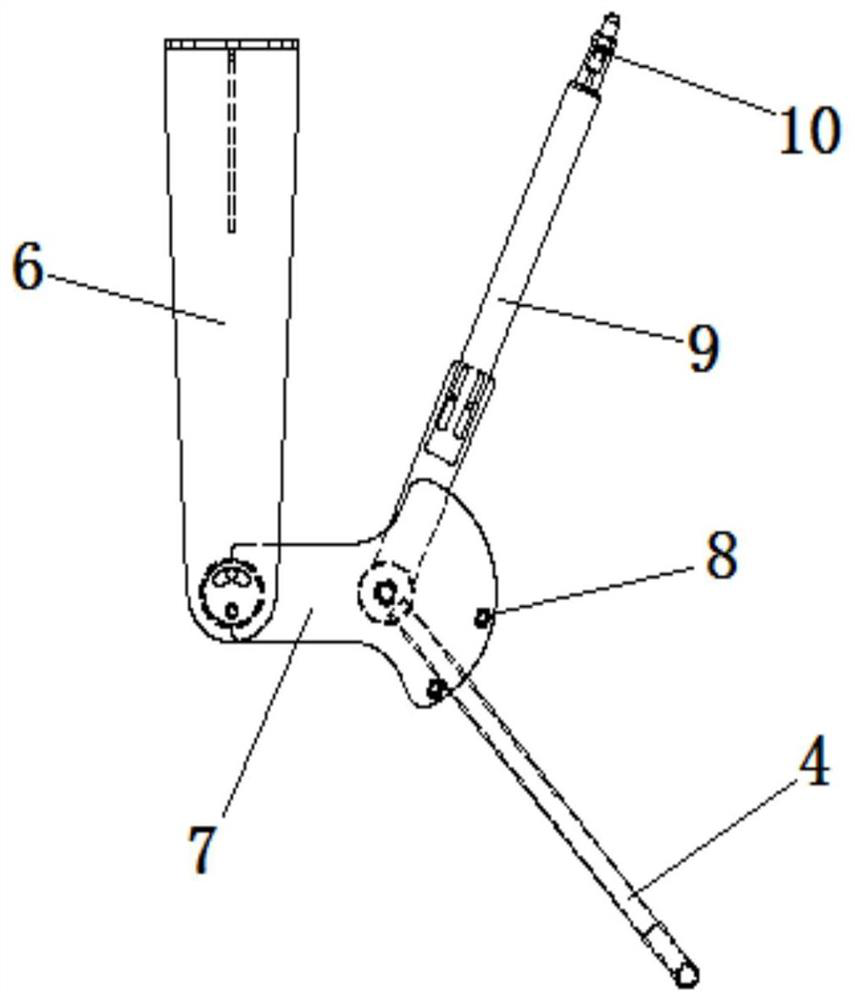

[0019] In the above structure, a tension rod 3 capable of swinging in a certain angle interval and a sensor device connected to the tension rod 3 are provided above the fabric in the water tank 1, and the control signal for controlling the relative reverse rotation of the cloth lifting wheel 2 corresponds to Due to the swing of the tension rod 3, that is, the swing of the tension rod 3 drives the sensor devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com