A reactive dyeing post-processing process

A reactive dye and post-processing technology, applied in the field of cotton knitting dyeing process, can solve the problems of many times of water use, long washing time, and high energy consumption, and achieve the effects of saving steam and electricity, reducing high-temperature washing time, and reducing production consumption costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

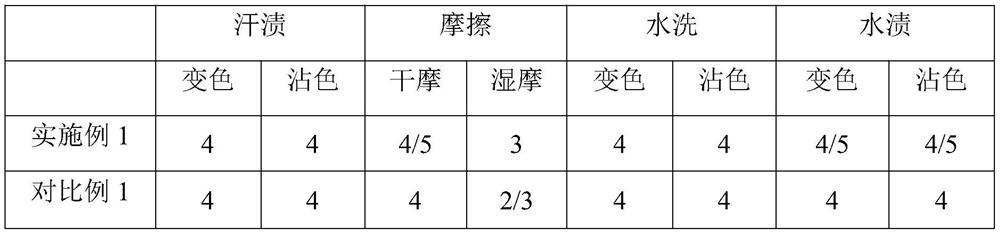

Embodiment 1

[0033] The post-processing steps provided by the present invention specifically include:

[0034] Wash with water at 60°C for 6 min → wash with water at 70°C for 6 min → add 2.5% pickling solution, neutralize pickling at 70°C for 6 min → add 1% saponifier, soap at 90°C for 6 min → wash with water at 80°C for 6 min → wash with water at 70°C for 6 min → wash with water at 40°C 6min → emulsification.

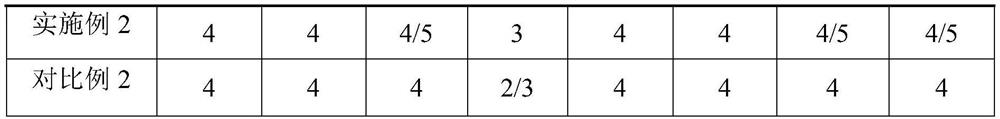

Embodiment 2

[0044] The post-processing steps provided by the present invention specifically include:

[0045]Wash with water at 60°C for 6 min → wash with water at 70°C for 6 min → add 2.5% pickling solution, neutralize pickling at 70°C for 6 min → add 1% saponifier, soap at 90°C for 6 min → wash with water at 80°C for 6 min → wash with water at 70°C for 6 min → wash with water at 40°C 6min.

Embodiment 3

[0056] The post-processing steps provided by the present invention specifically include:

[0057] Wash with water at 60°C for 6 min → wash with water at 70°C for 6 min → add 1.5% pickling solution, neutralize and pickle at 70°C for 6 min → add 0.8% saponifier, soap at 90°C for 6 min → wash with water at 40°C for 6 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com