C-type starting forward curve multi-blade centrifugal fan impeller and manufacturing method

A centrifugal fan, a pre-starting technology, applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as unreasonable flow passages between blades, failure to form arc lines, and reduced aerodynamic performance to achieve good blades. Between the flow channels, to achieve the effect of drag reduction and improve the effect of flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in further detail below in conjunction with accompanying drawing:

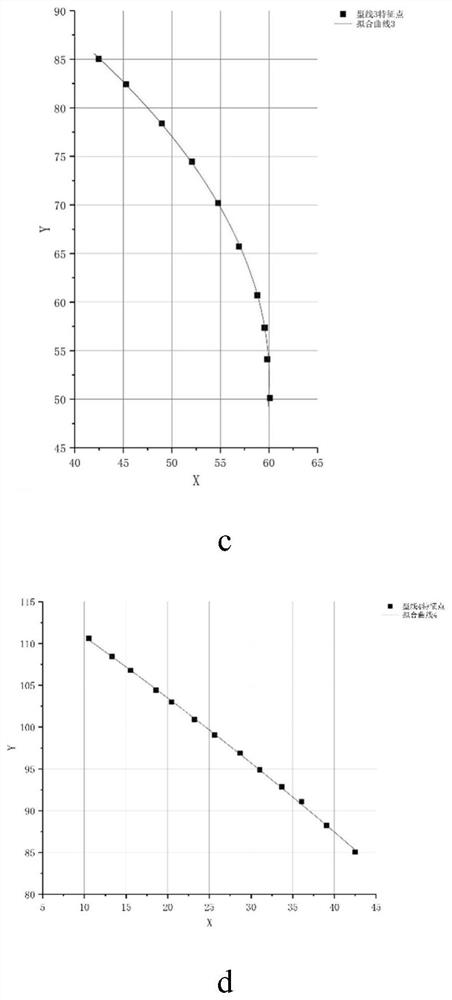

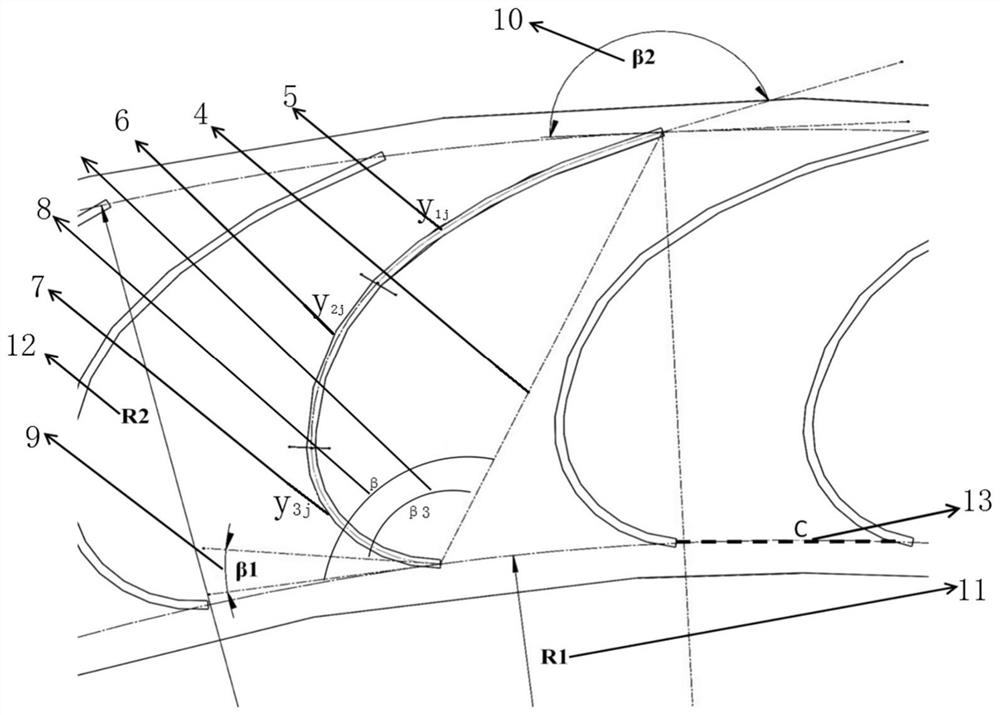

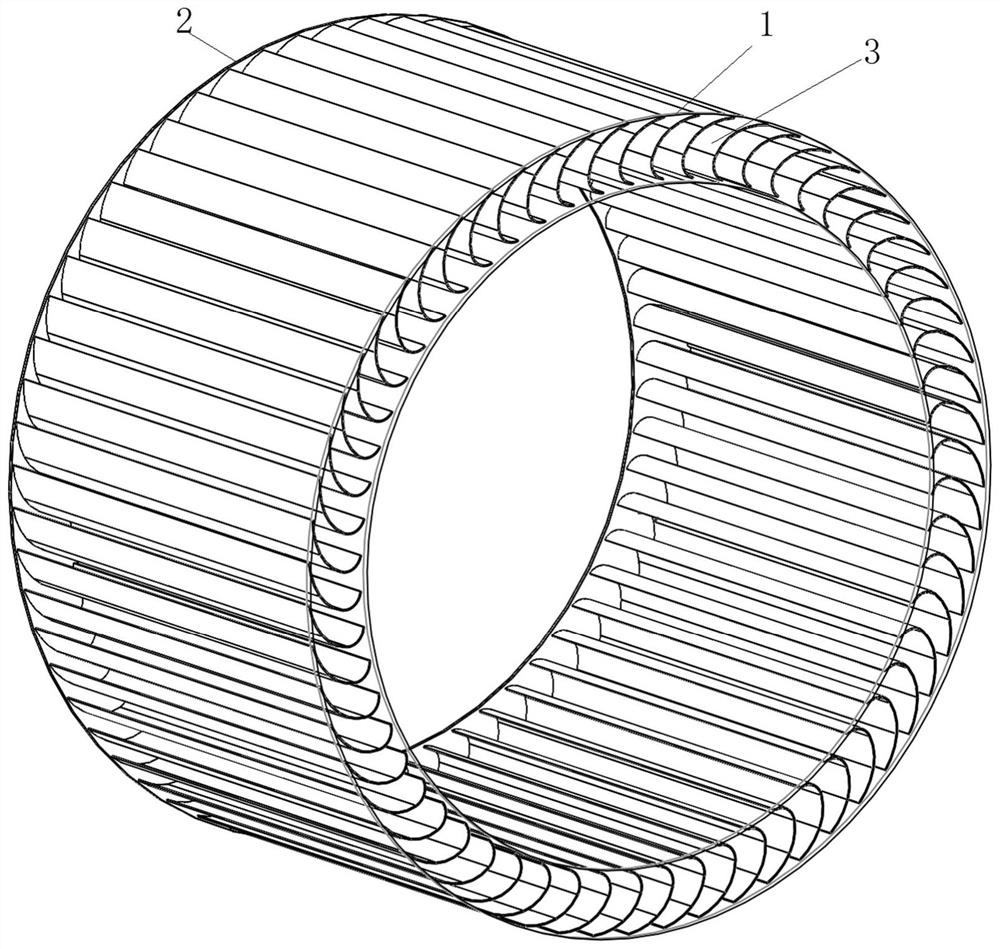

[0046] Such as figure 1 , figure 2 As shown, a C-type starting forward curved multi-blade centrifugal fan impeller includes an impeller front disk 1, an impeller rear disk 2, and a circular array of blades 3 between the impeller front disk and the impeller rear disk, and the blades 3 are perpendicular to the width of the impeller. The section in the direction is a C-shaped section, and the middle arc of the C-shaped section is the first curve y 1j 5. The second curve y 2j 6 and the third curve y 3j 7 Fitting curves connected in sequence, that is, the equation of the center line of the fish body;

[0047]

[0048] where the first curve y 1j The end of 5 is the blade trailing edge, the third curve y 3j The end of 7 is the leading edge of the blade; the line between the trailing edge of the blade and the leading edge of the blade is the blade chord length 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com