Gear with overload protection function

An overload protection and gear technology, which is applied to belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as motor burnout, transmission parts broken or damaged, gear broken teeth, etc., to prevent gears The effect of broken teeth, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

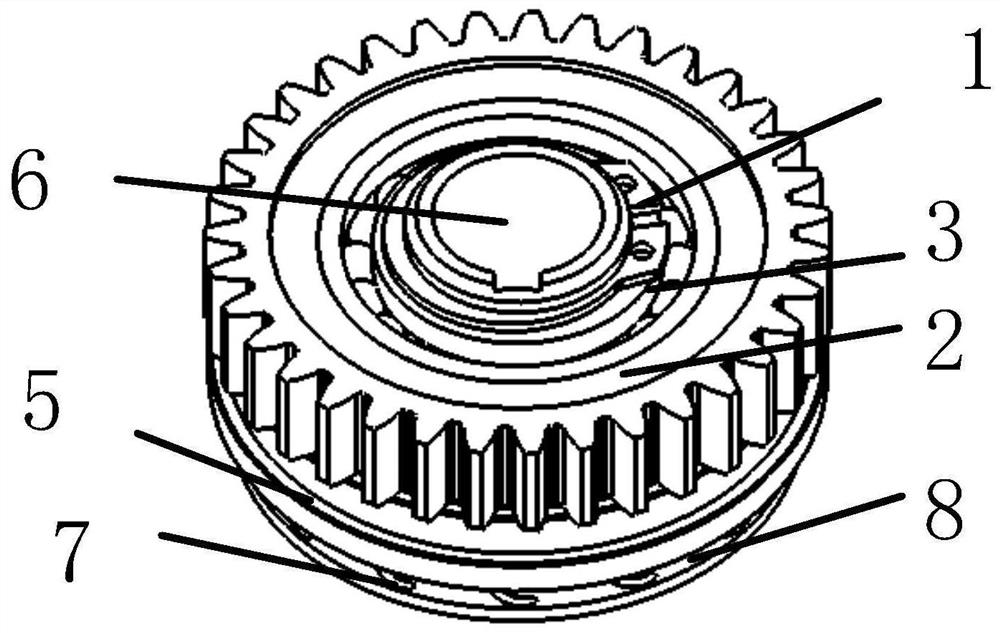

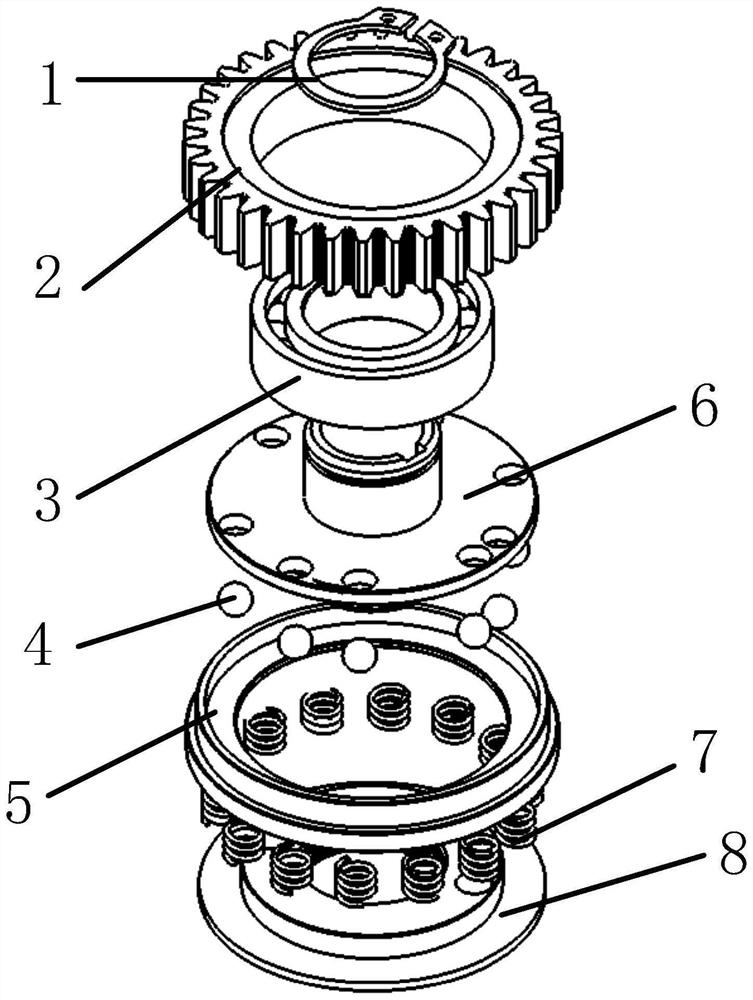

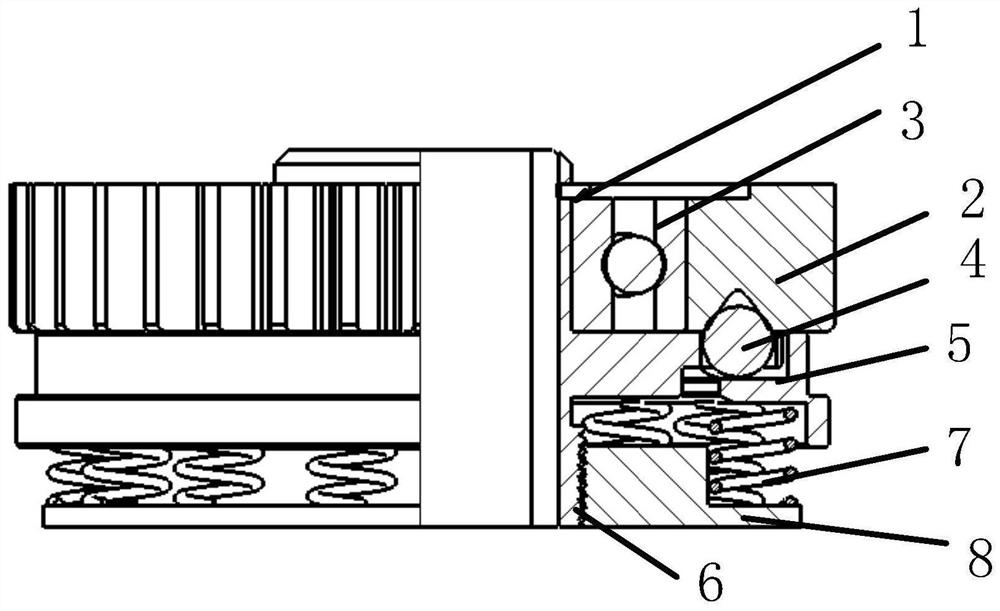

[0014] A gear with an overload protection function is composed of a snap ring 1, a gear 2, a deep groove ball bearing 3, a ball 4, an outer ring 5, an inner ring 6, a spring 7, and an end cover 8. The inner ring 6 has a flat keyway for power input. The outer ring 5 is located below the inner ring 6. The outer ring 5 is connected to the end cover 8 through the spring 7. The end cover 8 is threaded to the inner ring 6; the hole on the edge of the inner ring 6 The ball 4 is placed inside, and the gear 2 corresponding to the hole has a hemispherical hole, and then the inner ring 6 is connected with the gear 2 through the deep groove ball bearing 3, and is fixed with the snap ring 1.

[0015] There is a groove on the contact side of the gear 9 and the large ball 4, which can ensure that when the gear 9 is disengaged from the inner ring 6, the gear 9 and the inner ring 6 will slide relative to each other, and the ball 4 can return to the hole after sliding 360° Inside, the disc spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com