Force moment sensor for output pinion of self-elevating platform elevating unit

A self-elevating platform and torque sensor technology, which is applied in the field of sensors, can solve the problem of no torque sensor and other problems, and achieve the effect of avoiding broken teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

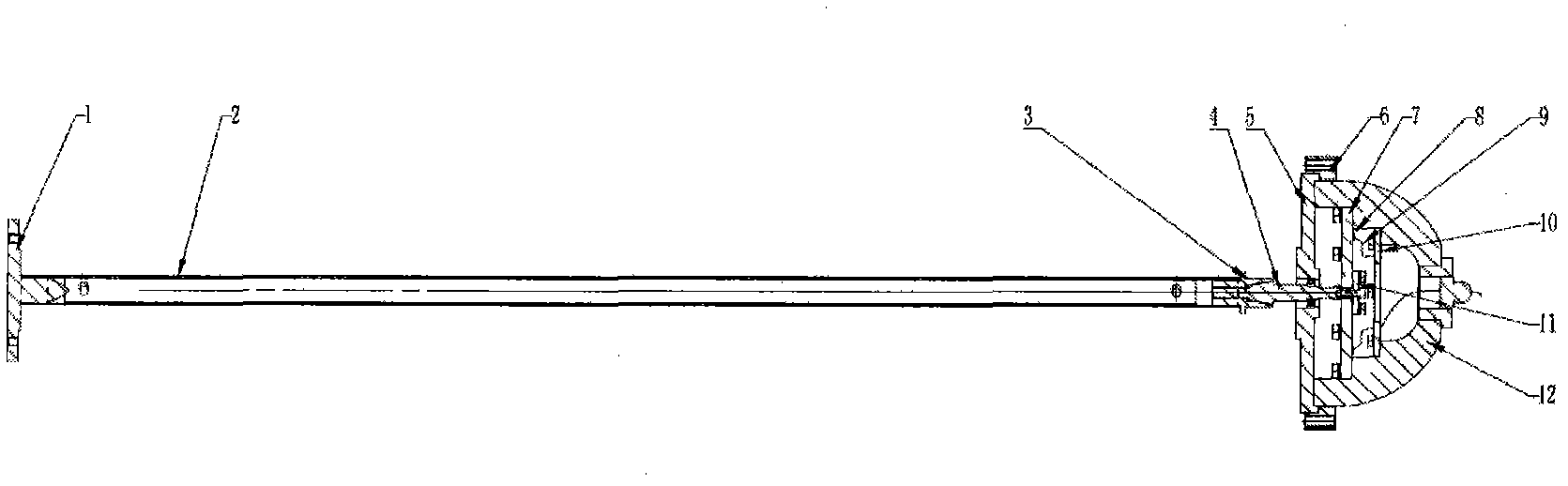

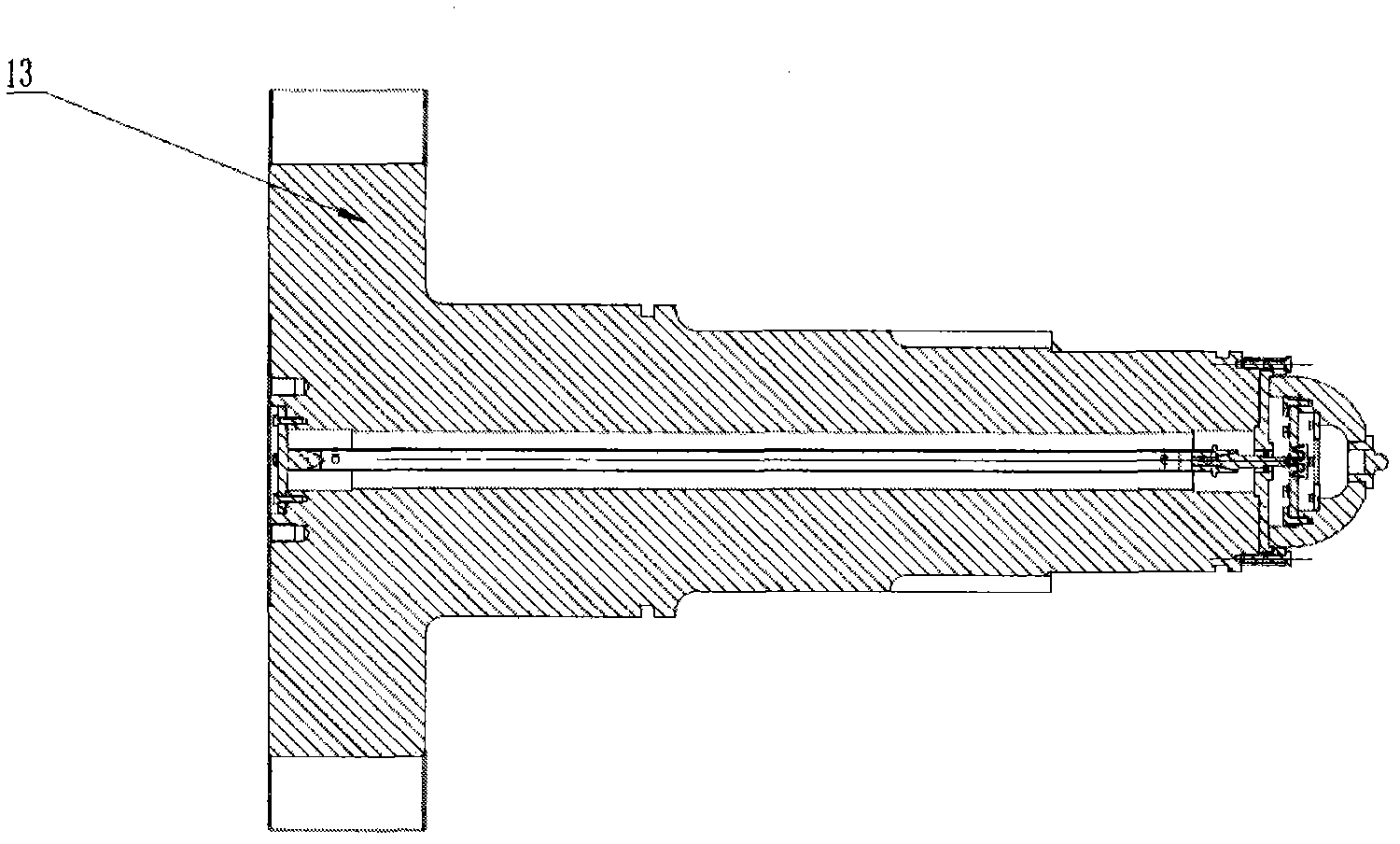

[0009] Example 1: Combining figure 1 , figure 2 , the present invention is a kind of torque sensor that is used for the output pinion of self-elevating platform lifting unit, and it is made of left input end cover (1), transmission rod (2), connecting head (3), torque input shaft (4), Sensor end cover (5), sensor fixing flange (6), sensor body (7), strain gauge (8), signal transmission line (9), signal processing circuit (10), sensor right end fixed end cover (11), sensor The casing (12) and the output pinion (13) are composed, the left input cover (1) is coaxially connected with the transmission rod (2) and threaded, and the transmission rod (2) is coaxially connected with the connecting head (3) and threaded, The connector (3) is coaxially connected with the torque input shaft (4), and the torque input shaft (4) is fixedly connected with the sensor body (7) through the fixed end cover (11) at the right end of the sensor, and fixed to the sensor end cover (5) through a bear...

Embodiment 2

[0010] Example 2: Combining figure 1 , figure 2 , the working principle of the present invention is as follows: the left end of the pinion shaft (13) is subjected to the effect of moment, so that the left and right sections of the pinion shaft (13) produce relative displacement, and the displacement passes through the left input end cover (1), the transmission rod (2), Connector (3), torque input shaft (4), fixed end cap (11) at the right end of the sensor are transmitted to the sensor body (7) fixedly connected to the right end of the pinion shaft (13) on the sensor housing (12), and are pasted on The strain gauge (8) on the strain beam of the sensor body (7) feels the deformation, so that the signal of the full-bridge circuit composed of the strain gauge (8) changes, and the changed signal is transmitted to the processing circuit (10) through the signal transmission line (9). After the corresponding processing, the obtained signal is transmitted to the external post-proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com