Building construction safety elevator

A technology for building construction and elevators, applied in elevators, elevators in buildings, mechanical equipment, etc., can solve the problems of high use frequency of elevators, affecting the use of elevator boxes, broken teeth of gears, etc., and achieve the effect of reducing impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

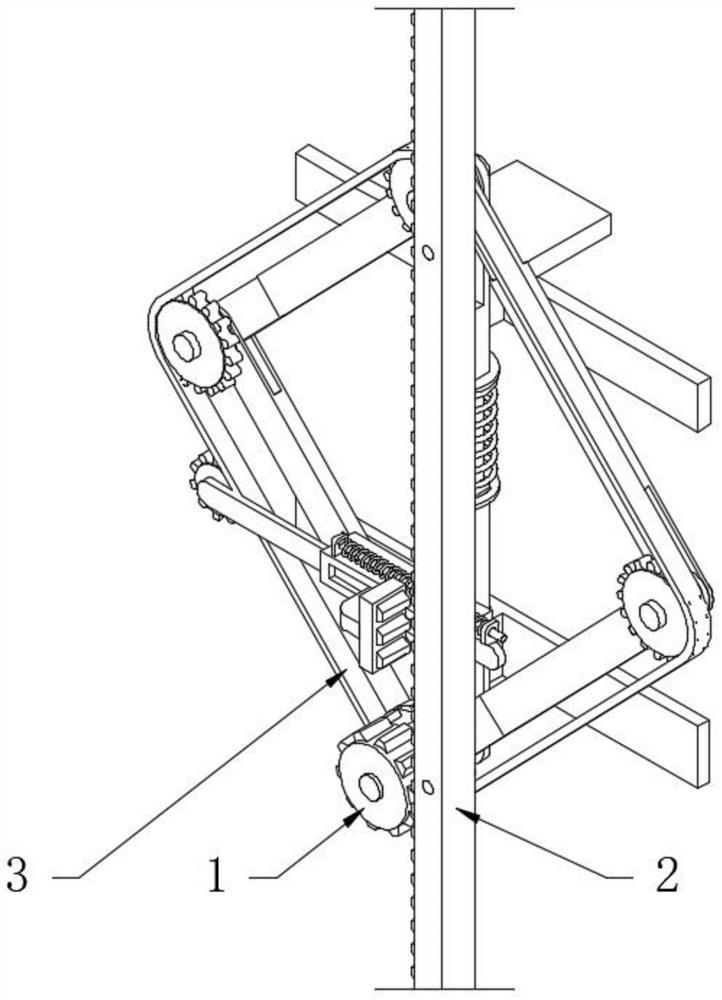

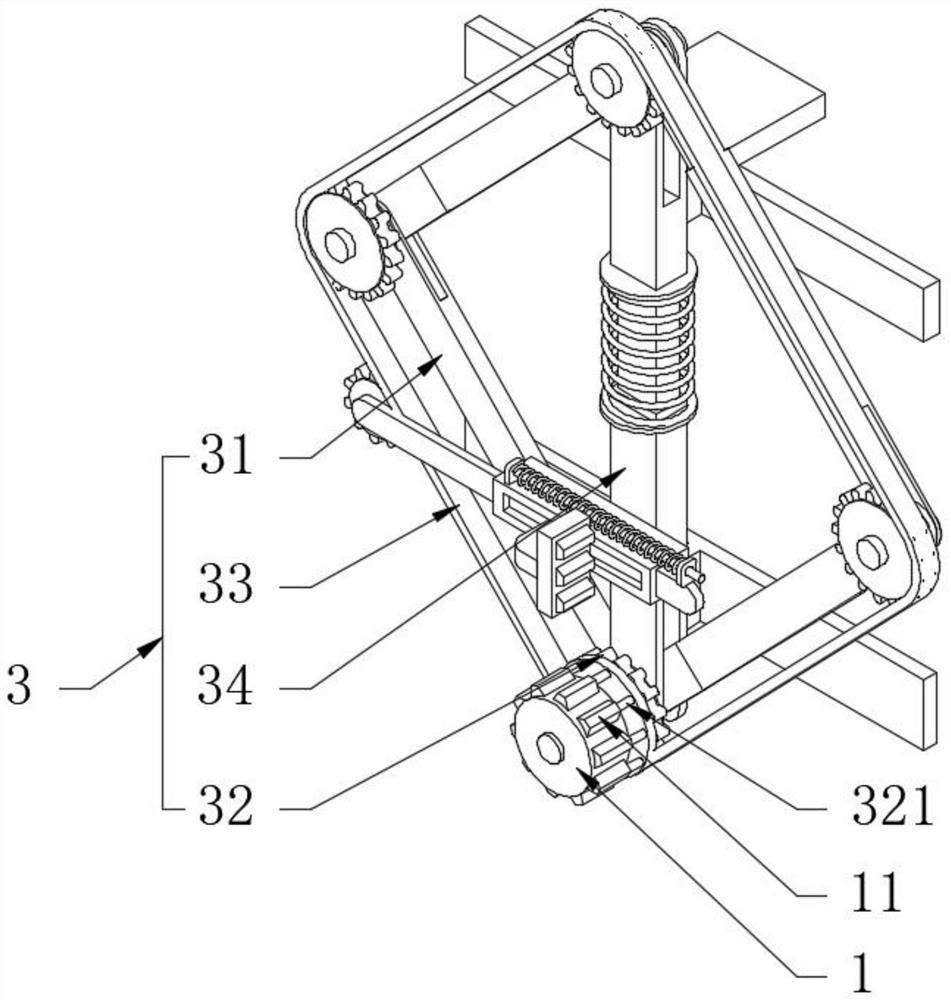

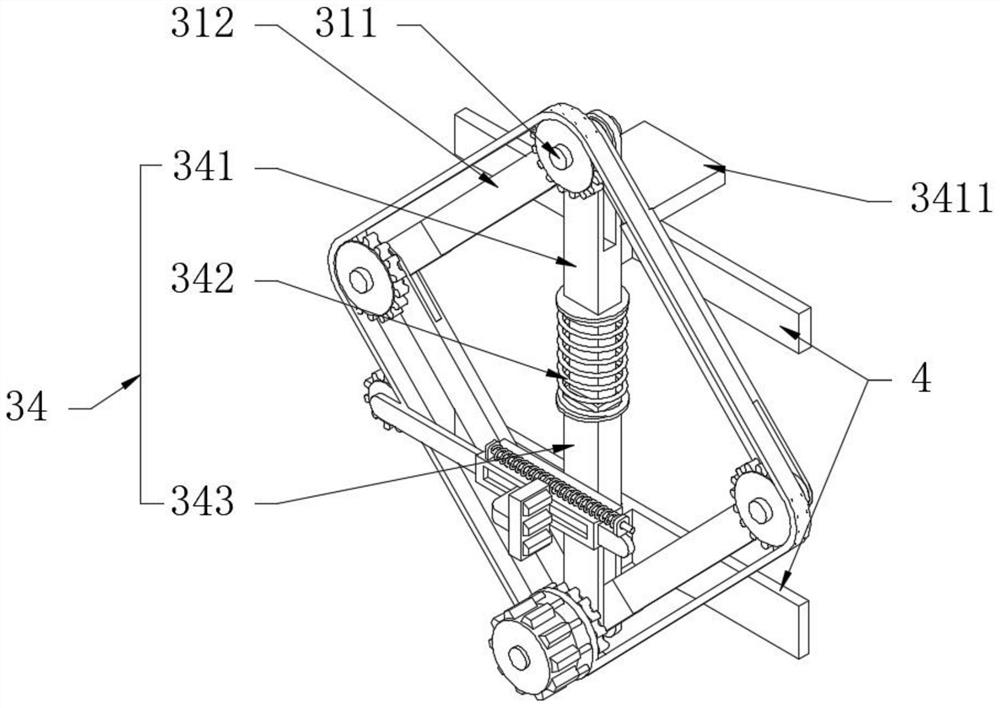

[0030] see Figure 1-3 , a building construction safety elevator, including a gear 1 and a rack 2 meshed with the gear 1. This embodiment is created on the basis of the existing gear 1 and the rack 2 meshing to realize lifting; it also includes a driving buffer chain Combination 3, the drive buffer chain combination 3 is the inventive structure of this embodiment, which can effectively solve the problem of broken teeth of the gear 1 and prolong the service life of the gear 1, and can also reduce the impact load of the drive input mechanism; the details are as follows The drive buffer chain combination 3 comprises a parallel hinge four-bar mechanism 31, a main sprocket wheel 32, a chain 33 and a spring damping rod 34, and the parallel hinge four-bar mechanism 31 is composed of four connecting rods with the same length. Rod 34 is positioned at parallel hinge four-bar mechanism 31 and is vertical distribution, and the two ends of this spring damping lever 34 are correspondingly c...

Embodiment 2

[0032] see Figure 4The difference from Embodiment 1 is that an elastic anti-drop condensation mechanism 5 is provided on the side of the lower sleeve 343 close to the rack 2, one end of the elastic anti-fall condensation mechanism 5 is engaged with the chain 33 and the other end is used in conjunction with the rack 2, The effect of this elastic anti-fall condensation mechanism 5 is that after the chain 33 in the embodiment 1 is accidentally disconnected, one end of the elastic anti-fall condensation mechanism 5 is instantly engaged with the rack 2. At this time, the lower casing 343 is fixed relative to the rack 2, and then It has anti-fall effect; specifically, the elastic anti-fall condensation mechanism 5 includes a rectangular guide sleeve 51, a guide plate 52, a return spring 53, a locking plate 54 and a traction sprocket 55, and the guide plate 52 is set on the rectangular guide sleeve 51 throughout. The traction sprocket 55 is rotatably connected to one end of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com