A method for manufacturing a low-temperature heavy-duty high-performance climbing gear shaft

A manufacturing method and high-performance technology, applied in the manufacture of tools, furnaces, heat treatment equipment, etc., can solve the problems of easy damage, high maintenance costs of climbing gear shafts, loose density and large shrinkage cavities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

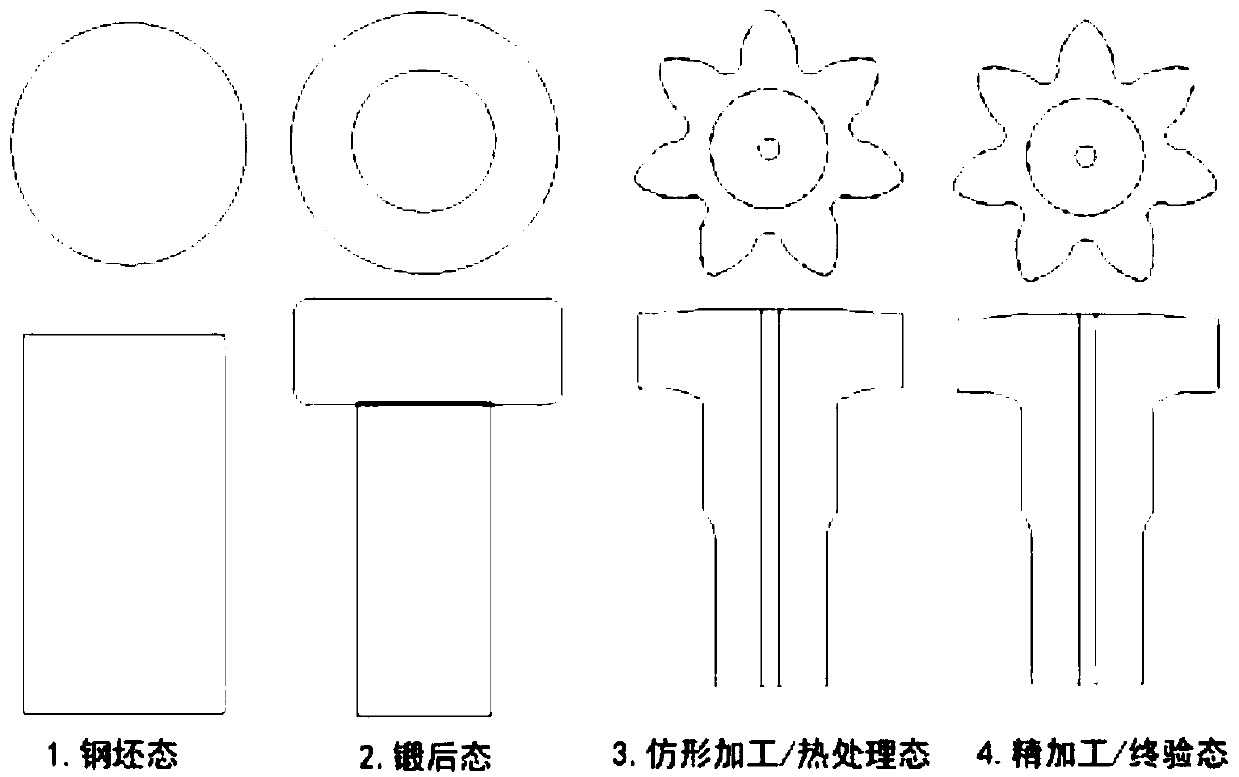

Image

Examples

Embodiment B1

[0102] Embodiment B1 prepares the climbing gear shaft according to the following steps:

[0103] Step 1, intercepting the above-mentioned alloy steel billet, carrying out chemical composition spectrum analysis on the intercepted alloy steel billet, and carrying out metallographic inspection on the alloy steel billet, checking the segregation structure remnants and grain size of the alloy steel billet: if the alloy steel billet has no Mixed crystals exist, and the coarsest grain size is above grade 7, then the alloy billet passes the metallographic inspection;

[0104] Step 2. Profiling the alloy billet, that is, rough turning and rough milling tooth profiling of the alloy billet, after the rough turning of the alloy billet, ultrasonic flaw detection is performed on the alloy billet to control the The dimensional error of each part of the above-mentioned semi-finished product is obtained, so as to obtain the semi-finished product of the climbing gear shaft;

[0105] Step 3, he...

Embodiment B2

[0116] Embodiment B2 prepares the climbing gear shaft according to the following steps:

[0117] Step 1, intercepting the above-mentioned alloy steel billet, first carrying out chemical composition spectrum analysis on the intercepted alloy steel billet, and then forging:

[0118] (1.1) Heating the alloy billet to 1250°C and keeping it warm for 8.5h;

[0119] (1.2) performing rough forging on the alloy steel billet, wherein the start forging temperature of the rough forging is 1150°C, and the final forging temperature of the rough forging is 1100°C;

[0120] (1.3) Diffusion annealing treatment is performed on the alloy billet, wherein the heating temperature of the diffusion annealing is 1150° C., and the temperature is kept for 8.5 hours;

[0121] (1.4) Finish forging the alloy billet, wherein the start forging temperature of the finish forging is 1050°C, and the finish forging temperature of the finish forging is 1000°C;

[0122] (1.5) Carry out metallographic inspection t...

Embodiment B3

[0135] Embodiment B3 prepares the climbing gear shaft according to the following steps:

[0136] Step 1, intercepting the above-mentioned alloy steel billet, first carrying out chemical composition spectrum analysis on the intercepted alloy steel billet, and then forging:

[0137] (1.1) Heating the alloy billet to 1250°C and keeping it warm for 8.5h;

[0138] (1.2) performing rough forging on the alloy steel billet, wherein the start forging temperature of the rough forging is 1150°C, and the final forging temperature of the rough forging is 1100°C;

[0139] (1.3) Diffusion annealing treatment is performed on the alloy billet, wherein the heating temperature of the diffusion annealing is 1150° C., and the temperature is kept for 8.5 hours;

[0140] (1.4) Finish forging the alloy billet, wherein the start forging temperature of the finish forging is 1050°C, and the finish forging temperature of the finish forging is 1000°C;

[0141] (1.5) Normalize and heat the alloy steel bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com