Large-caliber plastic butterfly valve

A large-diameter, plastic technology, applied in the field of large-diameter plastic butterfly valves, can solve the problems of uneven surface of the inner hole, low production efficiency, high cost, etc., achieve the effect of ensuring the out-of-roundness of the through hole, reducing the production process and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

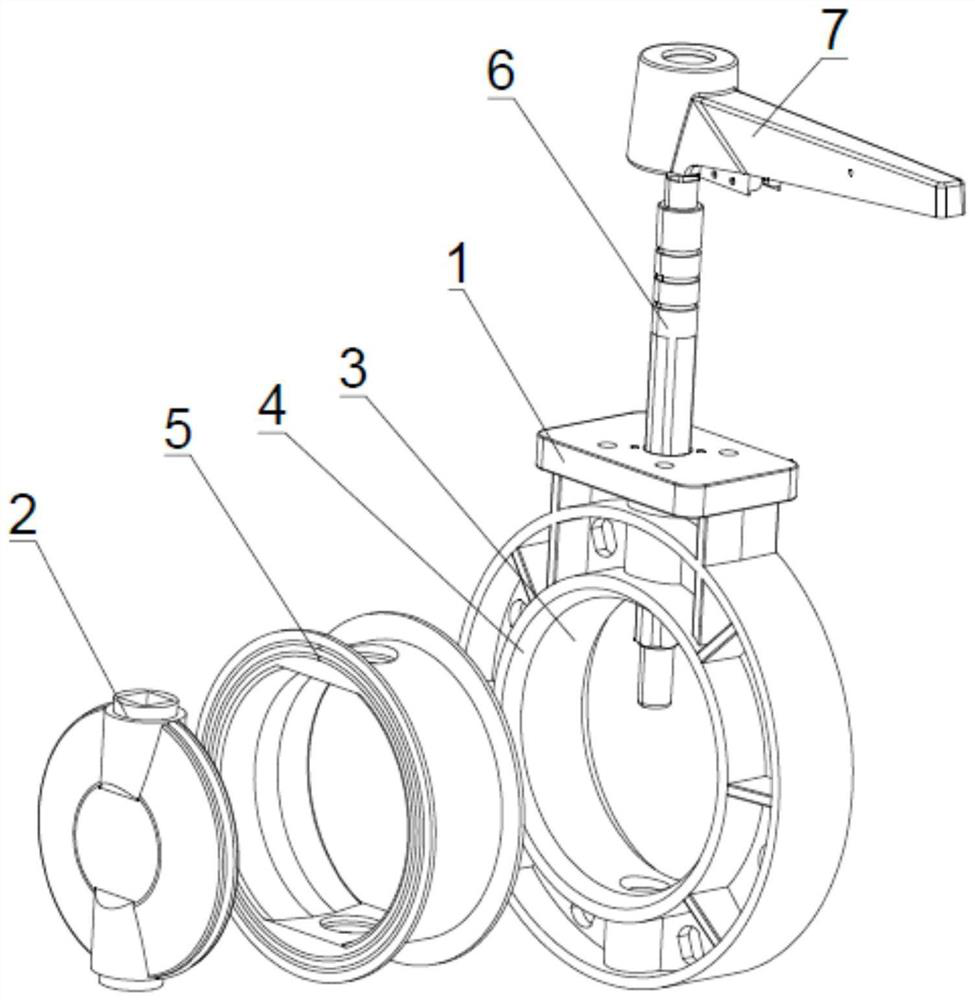

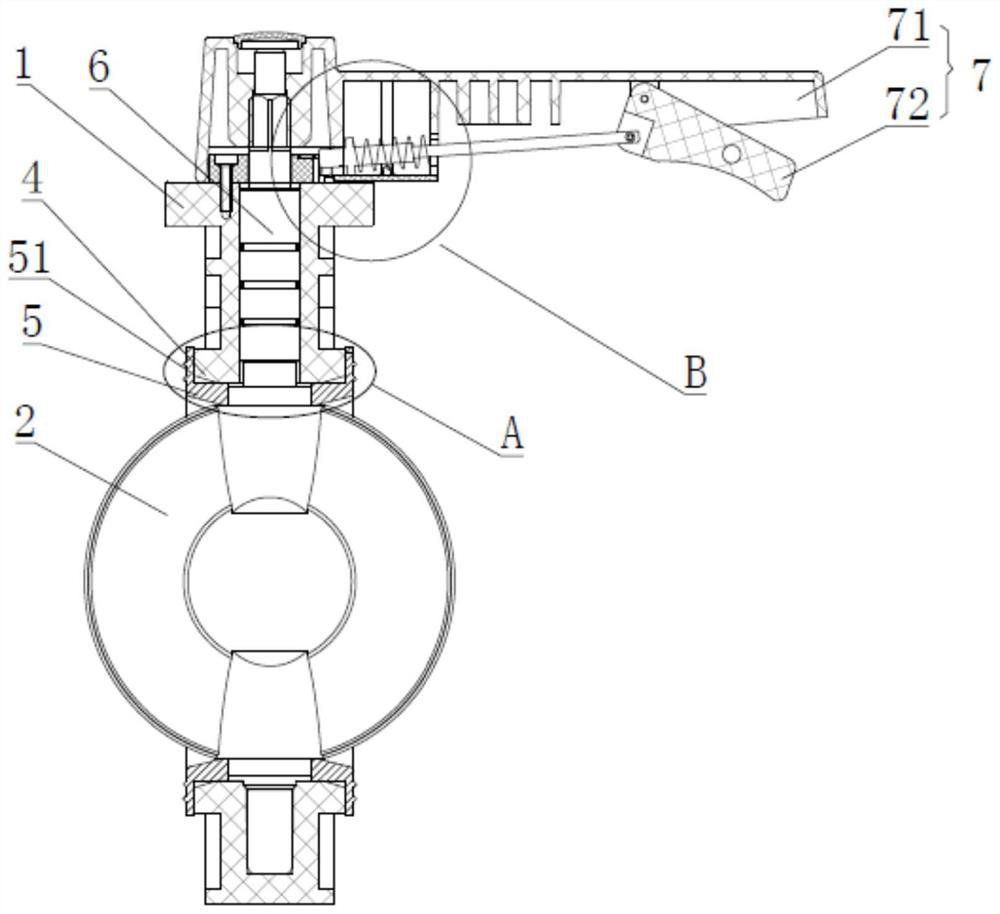

[0024] Such as Figure 1 to Figure 6 It is an embodiment of a large-diameter plastic butterfly valve, including a valve body 1 and a valve plate 2. The valve body 1 is provided with a through hole 3 for communicating with pipe materials, and the through hole 3 is connected with a transition part 4 for placing a gate 91. , the transition part 4 is connected with the inner wall of the through hole 3 , and the valve plate 2 is movably arranged in the through hole 3 and is sealed with the inner wall of the through hole 3 .

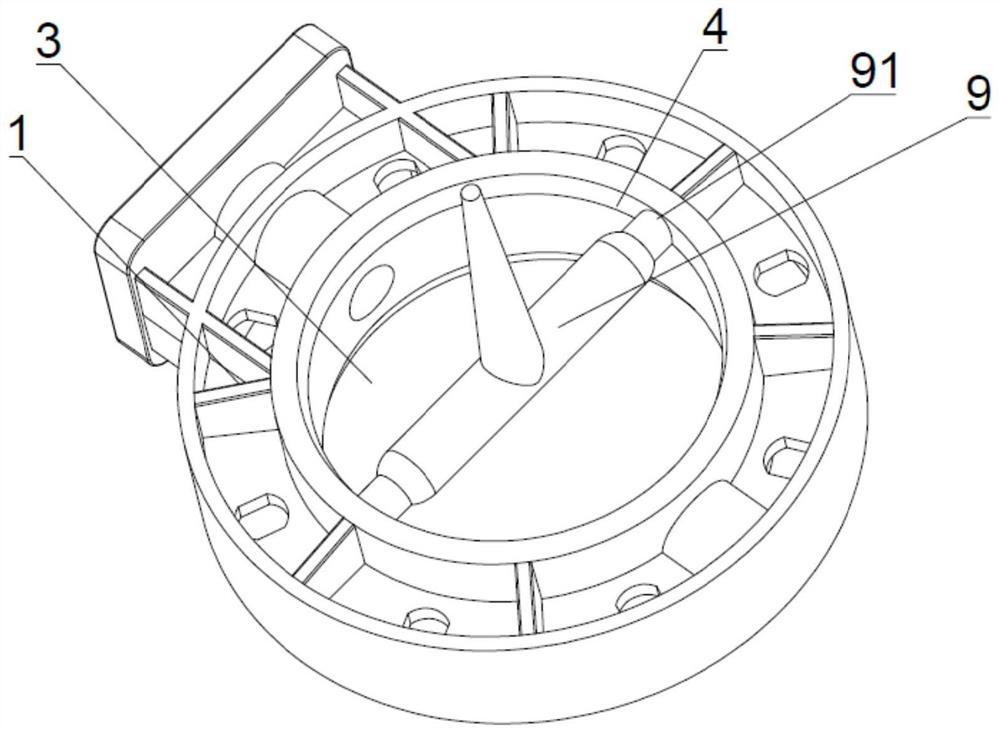

[0025] Such as image 3 As shown, the two gates 91 of the runner 9 can be respectively placed at positions corresponding to the transition portion 4 for injection molding.

[0026] Because there is an extreme situation, the thickness of the residual material left after the gate is cut off may be relatively large, which will affect the movement of the valve plate 2 in the through hole 3, so in this embodiment the transition part 4 is along the through hole 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com