Method for determining ultimate load of composite laminated plate after patching and repairing

A composite material layer, ultimate load technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of high computational efficiency and computational accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

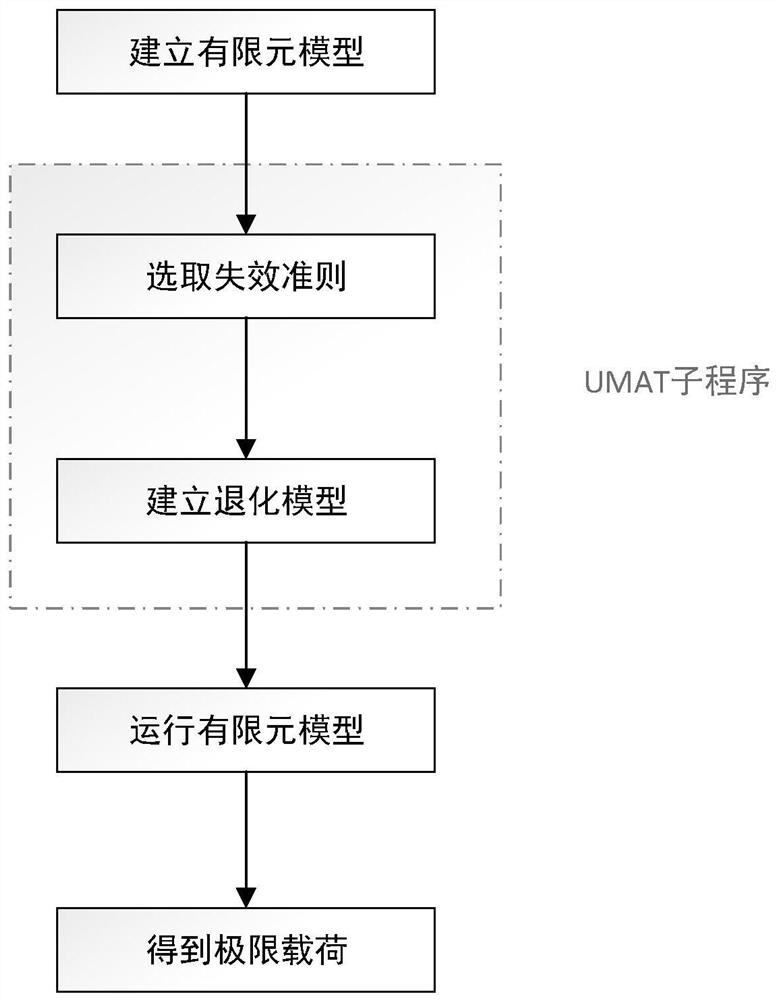

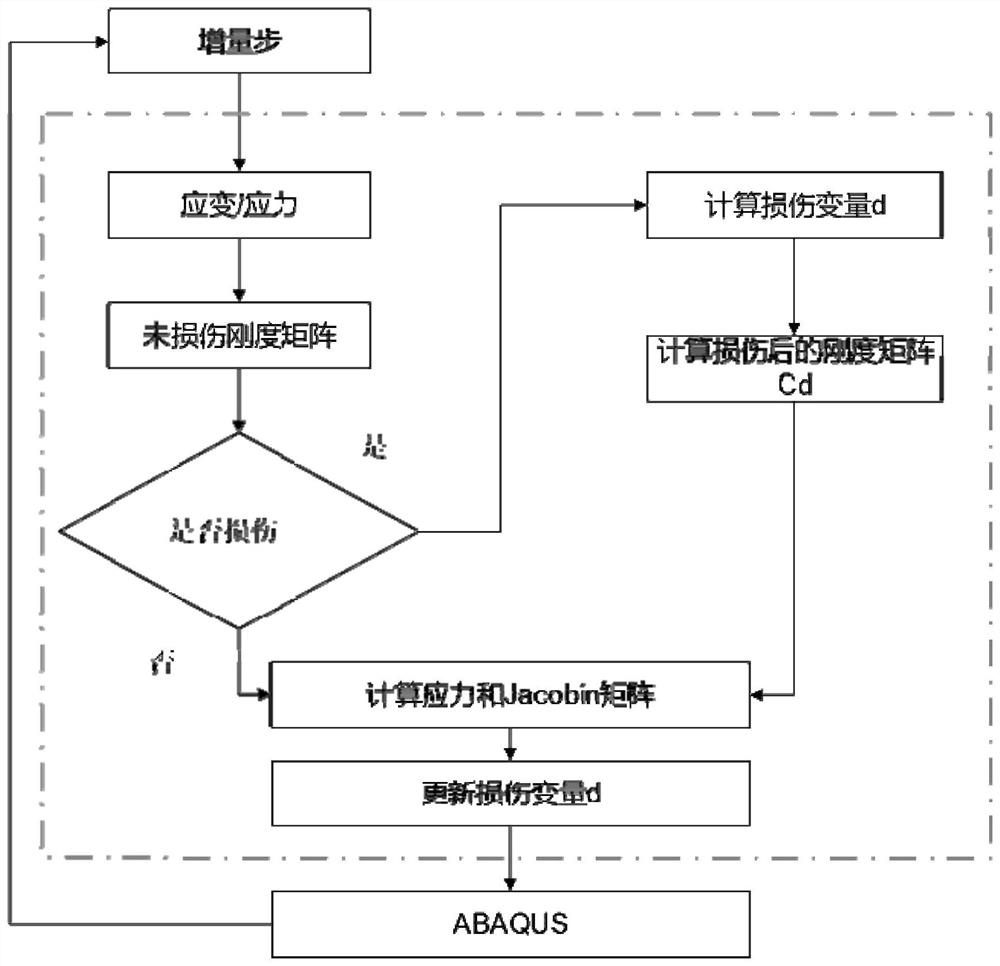

Method used

Image

Examples

Embodiment Construction

[0094] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0095] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

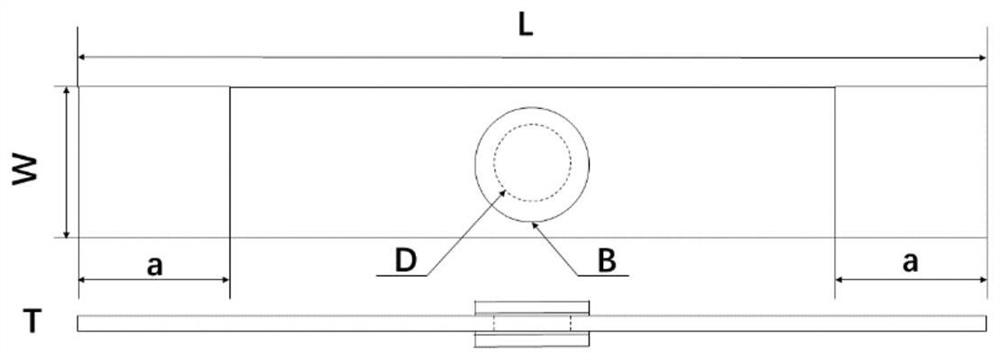

[0096] The finite element model is established in ABAQUS. Build a geometric model such as image 3 As shown, where: W=20mm is the width of the laminate, L=120mm is the length of the laminate, T=2mm is the thickness of the laminate, t=0.1mm is the thickness of the adhesive layer, a=20mm is the length of the reinforcing sheet, D is the diameter of the damaged hole, and B is the diameter of the patch. The parameter values of D and B are shown in Table 1, and the material properties are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com