Semiconductor module

A technology for semiconductors and shells, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as damage to moisture resistance and increase in the area of packaging materials, so as to reduce the amount of intrusion and reduce water permeability performance, and the effect of improving moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

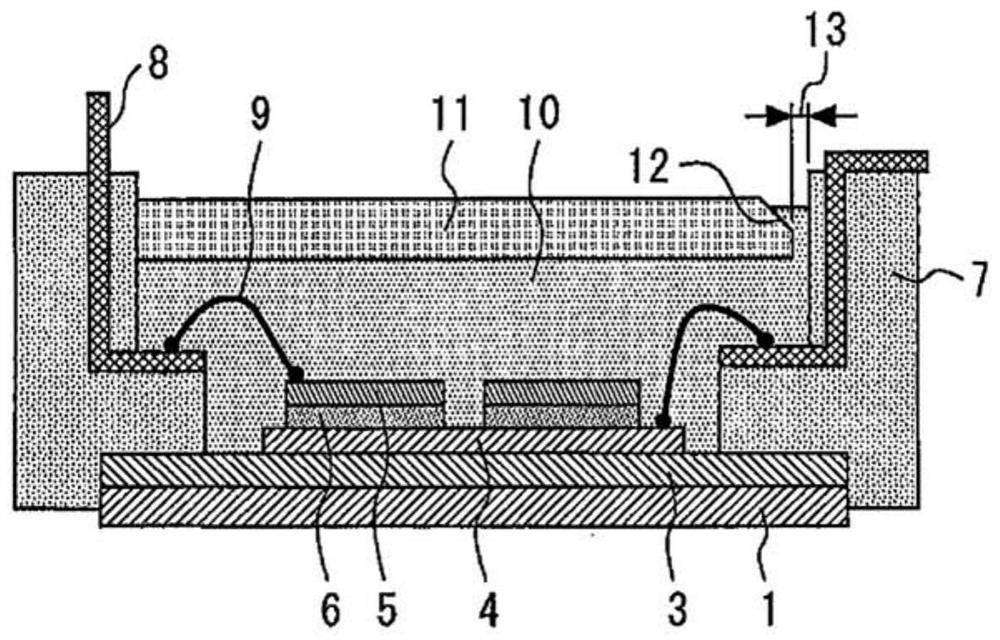

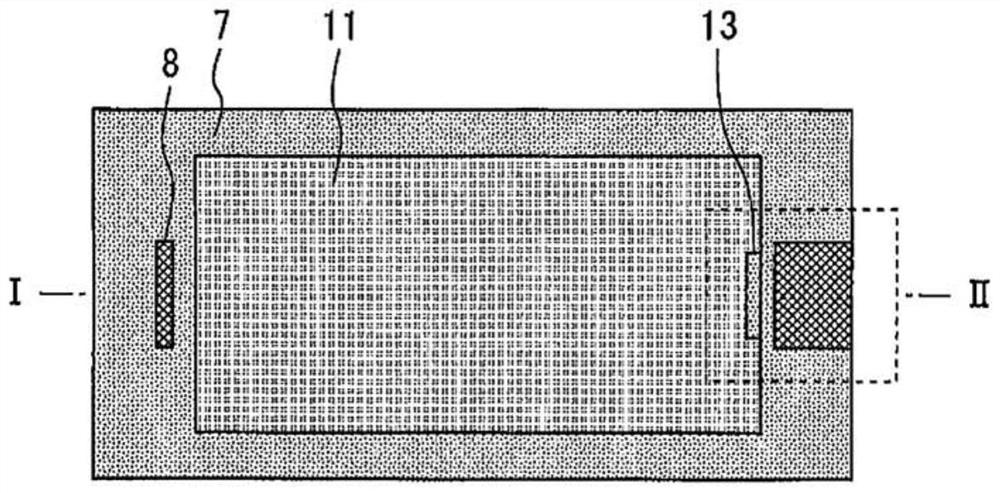

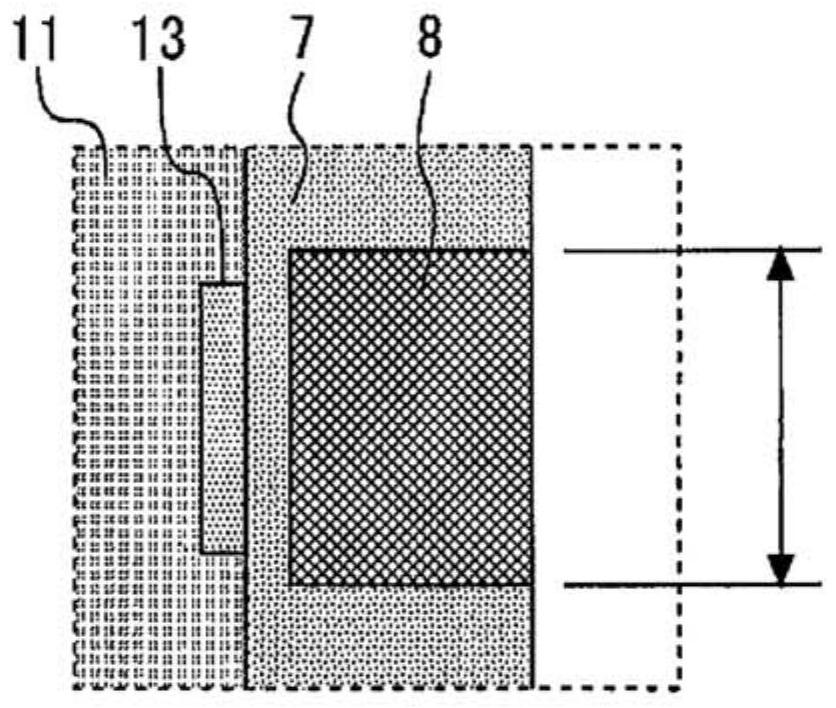

[0037] figure 1 It is a sectional view showing the semiconductor module according to the first embodiment. figure 2 It is a plan view showing the semiconductor module according to Embodiment 1. figure 1 is along figure 2 Sectional view of I-II. image 3 will be figure 2 A magnified top view of the portion enclosed by the dashed line.

[0038] An insulating layer 3 made of resin or ceramics is formed on the base plate 1 . A circuit pattern 4 is formed on the insulating layer 3 . The semiconductor chip 5 is mounted on the circuit pattern 4 via solder 6 . The semiconductor chip 5 is an IGBT chip or a diode chip. The case 7 is bonded to the outer peripheral portions of the base plate 1 and the insulating layer 3 so as to surround the circuit pattern 4 and the semiconductor chip 5 . The terminal electrodes 8 of the case 7 are connected to the upper surface electrodes of the semiconductor chip 5 through wires 9 .

[0039] A packaging material 10 such as silicone gel is i...

Embodiment approach 2

[0045] Figure 7 It is a sectional view showing the cover of the semiconductor module according to the second embodiment. Figure 8 It is a sectional view showing the semiconductor module according to the second embodiment. In the present embodiment, a tapered protrusion 14 whose central portion protrudes toward the sealing material 10 is provided on the lower surface of the cover 11 .

[0046] Figure 9 It is a cross-sectional view showing the manufacturing process of the semiconductor module according to the second embodiment. Even if air bubbles are formed at the interface between the packaging material 10 and the cover 11 when the cover 11 is placed on the upper surface of the packaging material 10, the air bubbles will be squeezed out along the tapered portion of the protrusion 14, from the casing 7 and the cover 11. The gap 13 in between is drained. As a result, the function of discharging air bubbles is higher than that of the first embodiment. Furthermore, the area ...

Embodiment approach 3

[0048] Figure 10 It is a perspective view showing the lower surface side of the cover of the semiconductor module according to the third embodiment. Figure 11 It is a plan view showing the cover of the semiconductor module according to the third embodiment. Figure 12 is along Figure 11 Sectional view of I-II. Figure 13 It is a side view showing the cover of the semiconductor module according to the third embodiment. Figure 14 It is a bottom view showing the cover of the semiconductor module according to the third embodiment.

[0049] A flow path 15 through which the sealing material 10 flows toward the end of the cover 11 is provided on the lower surface of the cover 11 . Walls for restricting the flow direction of the encapsulating material 10 are provided on both sides of the flow path 15 . A gap 13 between the housing 7 and the cover 11 is formed at the front end of the flow path 15 . Here, the encapsulating material 10 flows along the tapered portion of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com