Efficient mute solid-liquid separation waste processor

A technology of garbage disposer and solid-liquid separation, which is applied in grain treatment, chemical instruments and methods, solid waste removal, etc. It can solve the problems of inability to adjust the grid size, low space utilization rate, and poor filtering effect, and achieve Improve space utilization, avoid stirring in place, and avoid the effect of excessive volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

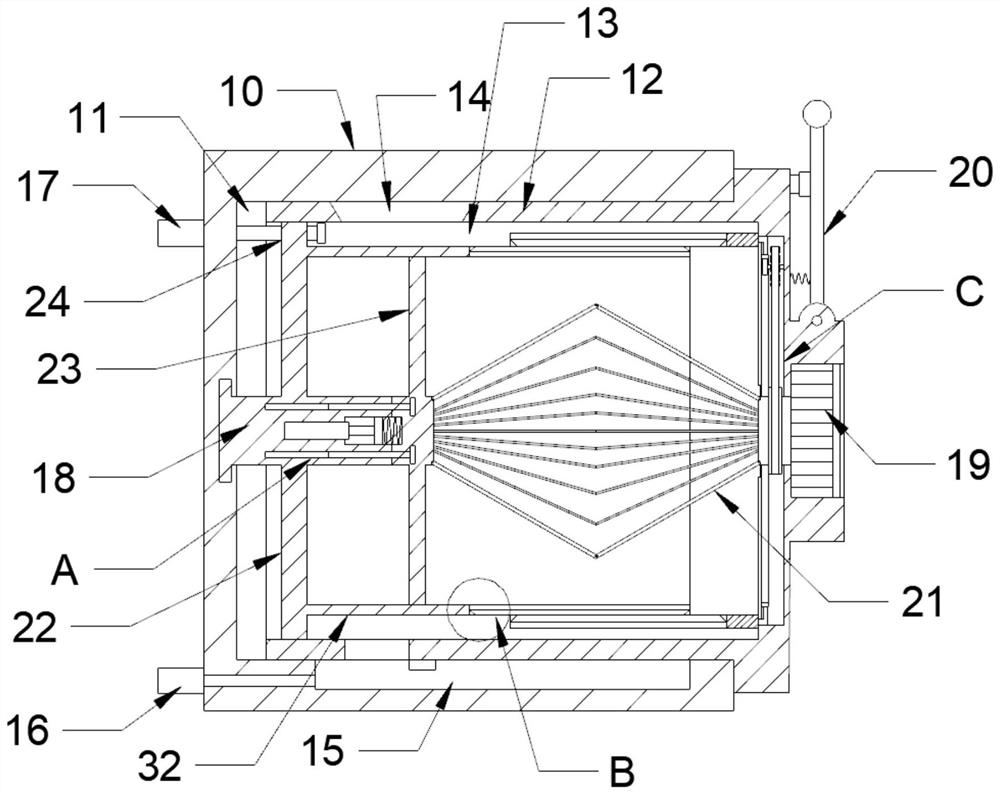

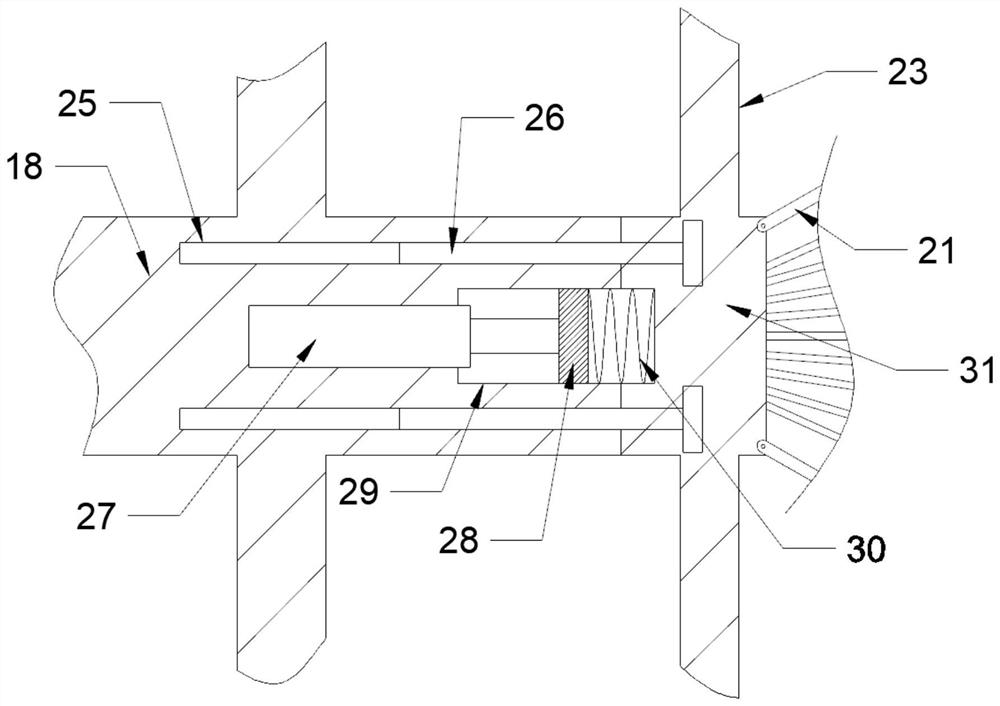

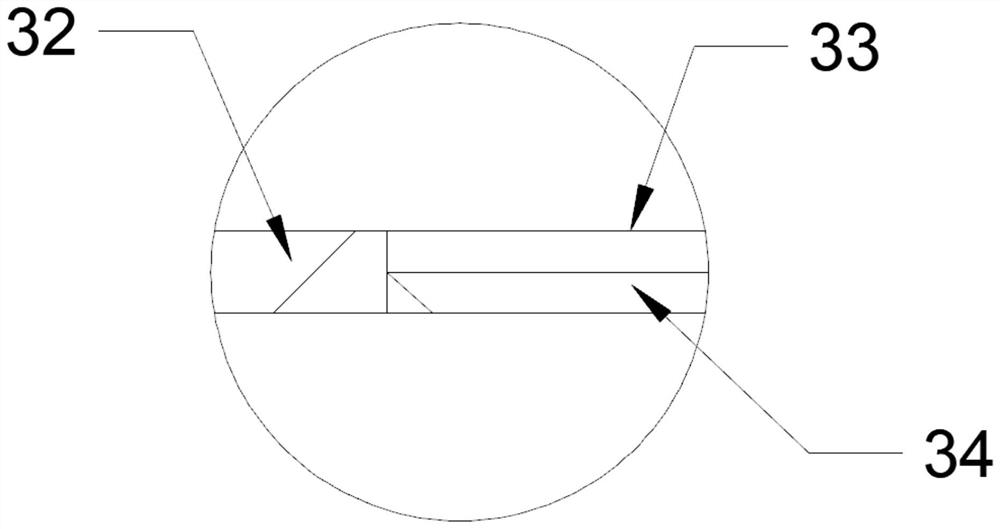

[0024] A high-efficiency silent solid-liquid separation garbage disposer described in conjunction with accompanying drawings 1-5 includes a housing 10, the housing 10 is provided with a first chamber 11 that opens outward, and the first chamber 11 is slidably provided with a movable body 12. The movable body 12 is provided with a second cavity 13 with an opening inward, the upper side of the movable body 12 is communicated with a passing groove 14, and the inner wall of the first cavity 11 is rotated and provided with a rotating shaft 18. The inner side of the rotating shaft 18 is fixed with a sealing circular plate 22, the outer side of the sealing circular plate 22 is provided with an inner barrel 32, the inner barrel 32 is slidably provided with an extrusion plate 23, and the outer wall of the second chamber 13 is rotated with a Outer barrel 49, the barrel cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com