Crusher

A crusher and unit technology, applied in the direction of magnetic separation, solid separation, grain processing, etc., can solve the problems affecting the free material flow of the conveyor belt, ferromagnetic material blockage, troublesome removal, etc., to reduce the force effect, prevent blockage, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

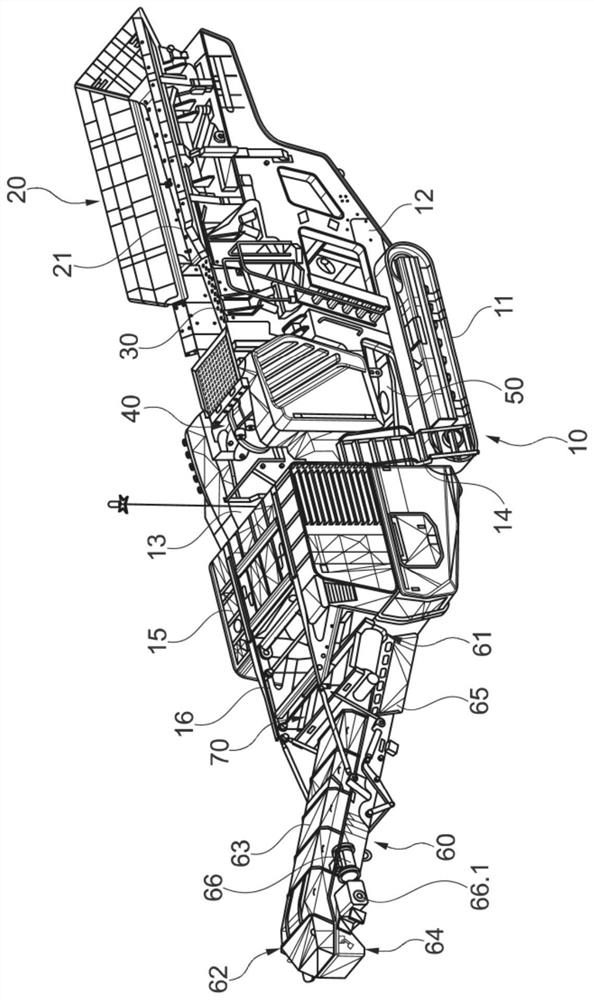

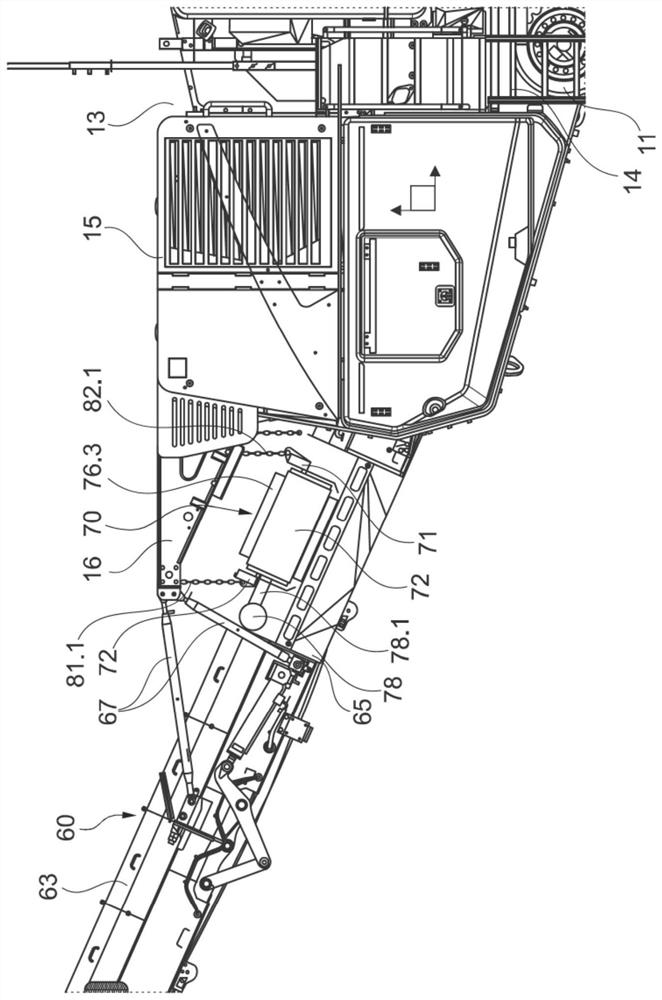

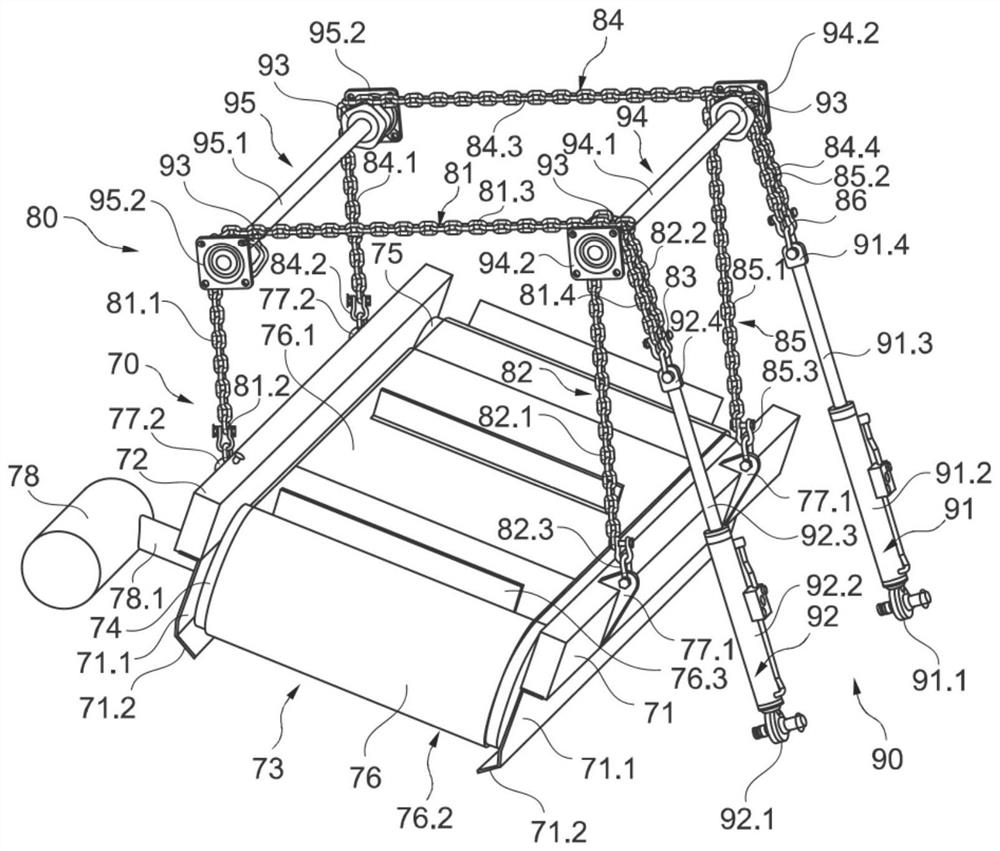

[0124] figure 1 A crusher 10 for comminuting mineral material is shown. The crusher 10 has a frame 12 which is supported by two carriages 11 , in particular two chain carriages. The rack 11 has a working area 13 which is accessible via a ladder 14 . Operators can carry out maintenance and repair work in the work area. The crushing space to the crusher, to the pre-screening section or to the delivery chute is also provided here for clearing material blockages or for mechanical setup if required.

[0125] The crusher 10 has an engine unit 15 in the front region. The engine unit 15 comprises an internal combustion engine which powers the individual units of the crusher 10 . The machine frame 12 also has a boom 16 on the front side, on which the conveyor belt unit 60 is suspended. The crusher 10 has a delivery unit 20 in the region of the rear end, which comprises a filling hopper. A conveying mechanism 21 , preferably a vibrating conveyor, is also arranged in the region of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com