Digital color matching and dyeing methods and color matching and dyeing systems

A digital and formula technology, applied in the field of fabric dyeing methods and related equipment, can solve the problems of large difference in dyeing matching, low color accuracy, unenvironmental protection, etc., to reduce the time required for color matching, good uniformity, and improved accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

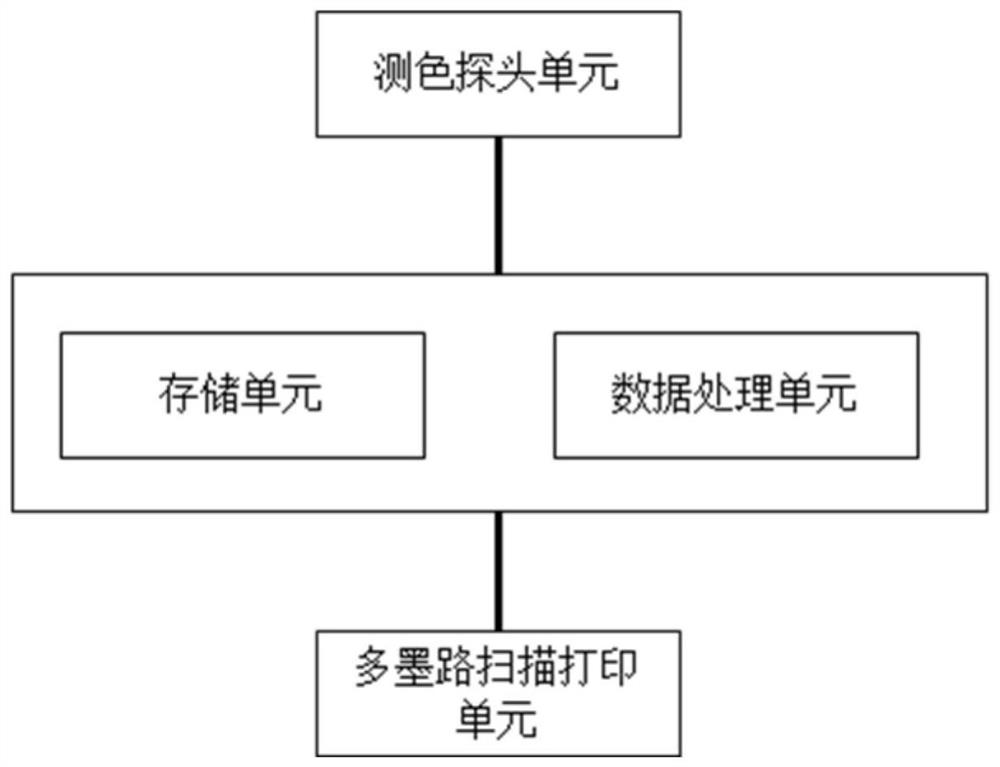

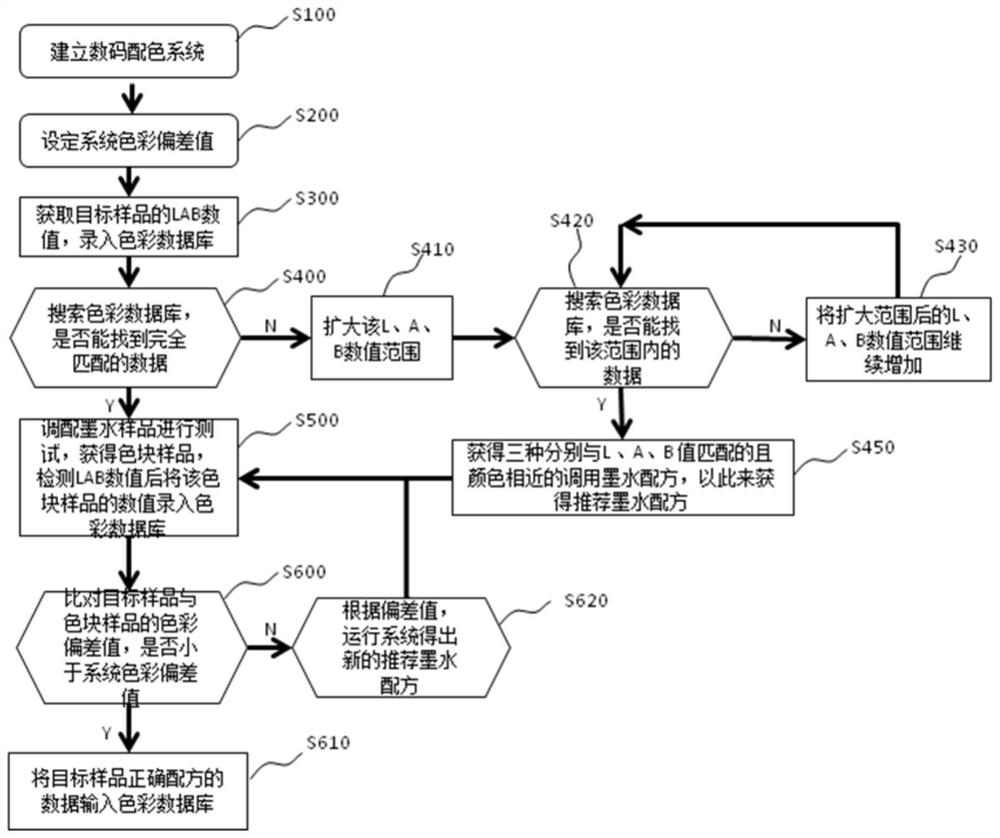

Method used

Image

Examples

example 1

[0104] The proofing and production process of completely matching colors (complete matching refers to the color difference DE<system deviation selection value):

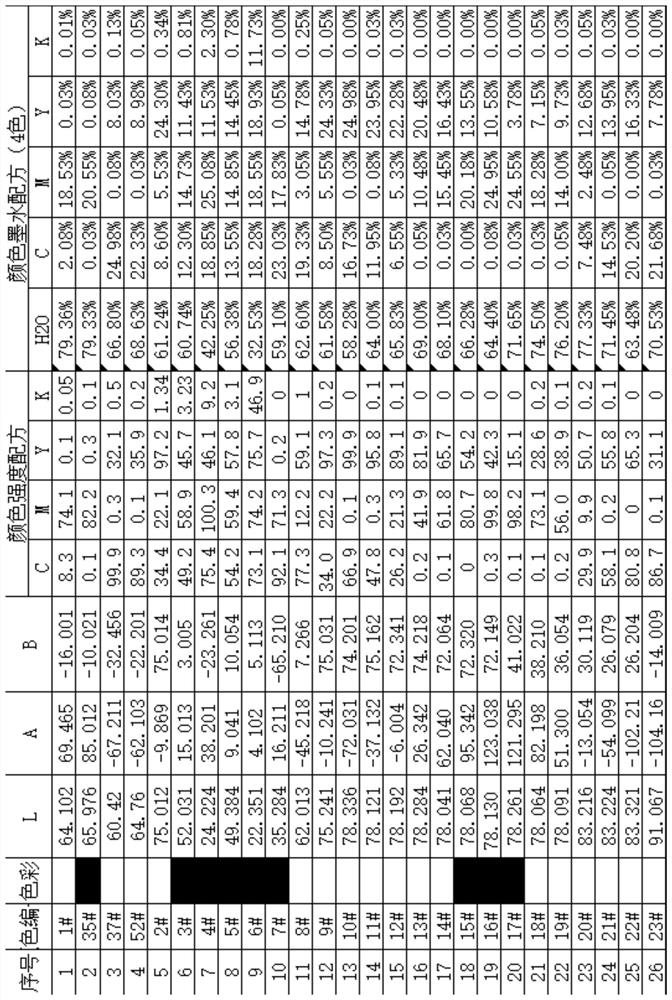

[0105] a. At S200, the incoming sample X is detected by the color measurement module, and the detected data are shown in Table 1:

[0106]

[0107] Table 1

[0108] b. At S300, enter the data into the "Color Database". At S400, the system finds a color through calculation according to the setting, and the color number is #1. The color data is shown in Table 2:

[0109]

[0110] Table 2

[0111] The system calculates the DE value of 1# color and target color:

[0112] DE=sqrt((64.102–64.300)^2+(69.465–69.813)^2+(-16.001-(-15.763))^2)=0.466

[0113] Since DE = 0.466 < 0.5, the color formulation is considered to be perfectly suitable for preparing the ink of the sample color.

[0114] c. At S500, prepare a sample according to the formula, and print the color block sample; then at S600, measure and compare the ...

example 2

[0124] Proofing and production process that cannot completely match the color but has a similar hue (DE> system deviation selection value):

[0125] a. At S300, the target sample Y is detected by the color measurement module, and the detected data are shown in Table 4:

[0126]

[0127] Table 4

[0128] b. At S400, after inputting the data into the "COMAT Color Database", a completely matching color cannot be found in the database, that is, no color formula with DE<0.5 can be found. At this time, enter the process S410, and the L, A , the B value gradually expands the search range (each time the range expands +-0.1), and then enters the process S420, until these three values can match within a positive and negative range value. After searching according to the sample Y, search the data in this range and judge the color at the same time, at S450, get three formulas, they are:

[0129]

[0130] table 5

[0131] Calculate the DE, DL, DA, and DB values of these three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com