Breathing type cable with high heat dissipation performance

A high heat dissipation and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of reduced lifespan, achieve the effects of increasing contact area, accelerating air flow, and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

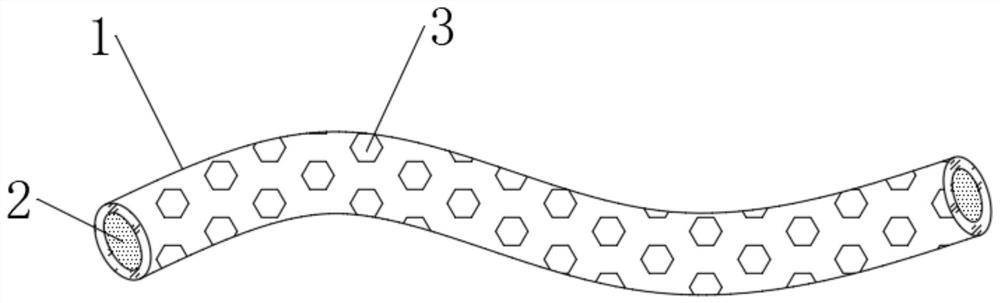

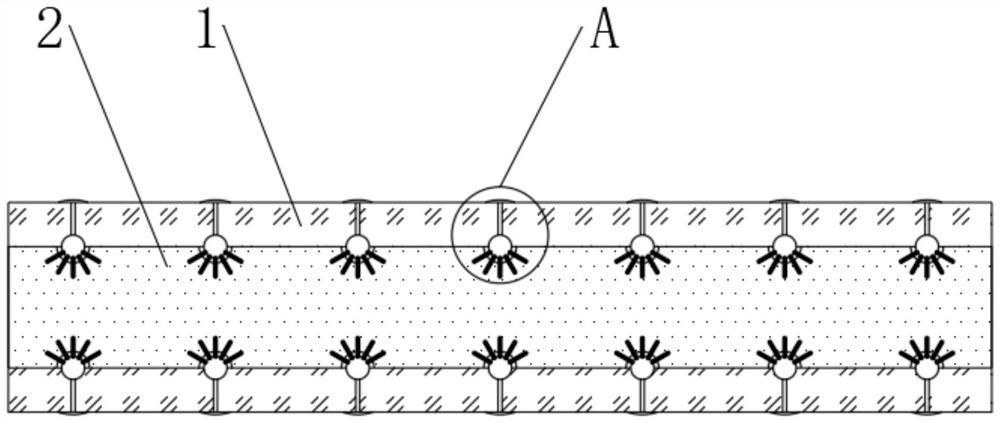

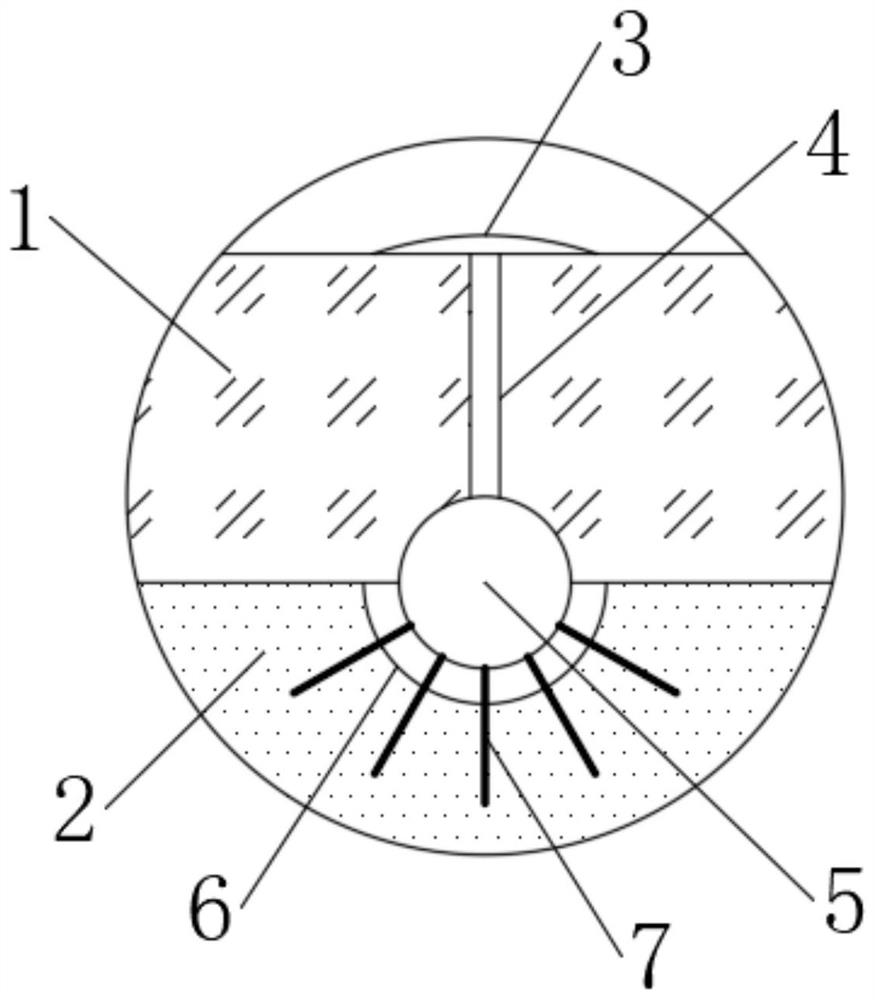

[0042] see Figure 1-3 , a breathing type high heat dissipation cable, including an outer sheath 1 and a cable body 2, and the cable body 2 is inserted inside the outer sheath 1, and the outer surface of the outer sheath 1 is connected with a plurality of evenly distributed outer heat dissipation spherical films 3. The outer heat dissipation spherical film 3 is connected with an inlay tube 4, and the inlay tube 4 penetrates the outer sheath 1 and extends to the inner side, and a plurality of outer heat dissipation spherical films are inlaid and connected between the outer sheath 1 and the cable body 2 3 corresponding to the inner heat-absorbing ball 5, and the inner heat-absorbing ball 5 is connected to the inlay tube 4, and the end of the inner heat-absorbing ball 5 far away from the inlay tube 4 is connected to the trigger hemispherical cover 6, and the inner heat-absorbing ball 5 is close to the trigger hemispherical cover One end of 6 is inlaid with a plurality of uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com