Container sealing glue and preparation method thereof

A sealant and container technology, applied in the field of sealant, can solve problems such as the comprehensive performance of the sealant not reaching the optimum state, the gap between the weld seam and the sealant, and the peeling off of the sealant, etc., and achieve a good working temperature range, weaken decomposition, and expansion The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

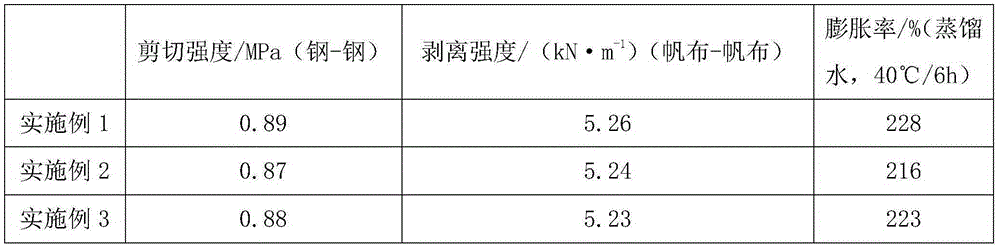

Examples

Embodiment 1

[0033] Prepare as follows:

[0034] S1: weigh each raw material by weight ratio;

[0035] S2: mixing gasoline, ethyl acetate and acetone to form a mixed solvent;

[0036] S3: after mixing the nitrile rubber and EPDM rubber, masticate three times on a plasticizer to obtain a plasticized product;

[0037] S4: Sodium acetate, sodium formate, sodium acrylate, sodium polyacrylate, cross-linked-polyisobutylene-grafted maleate sodium salt are sequentially added to the masticated material obtained in S3 and mixed for 10 minutes, followed by sericite and vulcanized paste. , diatomite, UV stabilizer, antioxidant, rutile titanium dioxide, light calcium carbonate, talc, continue to mix, extrude and slice;

[0038] S5: Add the kneading sheet obtained in S4 to the mixed solvent obtained in S2, stir until it is completely dissolved, and send it to a three-roller for grinding until it is fine and uniform to obtain a sealant.

Embodiment 2

[0040] Prepare as follows:

[0041] S1: weigh each raw material by weight ratio;

[0042] S2: mixing gasoline, ethyl acetate and acetone to form a mixed solvent;

[0043] S3: after mixing the nitrile rubber and EPDM rubber, masticate three times on a plasticizer to obtain a plasticized product;

[0044] S4: Sodium acetate, sodium formate, sodium acrylate, sodium polyacrylate, cross-linked-polyisobutylene-grafted maleate sodium salt are sequentially added to the masticated material obtained in S3 and mixed for 9 minutes, followed by sericite and vulcanized paste. , diatomite, UV stabilizer, antioxidant, rutile titanium dioxide, light calcium carbonate, talc, continue to mix, extrude and slice;

[0045]S5: Add the kneading sheet obtained in S4 to the mixed solvent obtained in S2, stir until it is completely dissolved, and send it to a three-roller for grinding until it is fine and uniform to obtain a sealant.

Embodiment 3

[0047] Prepare as follows:

[0048] S1: weigh each raw material by weight ratio;

[0049] S2: mixing gasoline, ethyl acetate and acetone to form a mixed solvent;

[0050] S3: after mixing the nitrile rubber and EPDM rubber, masticate twice on a plasticizer to obtain a plasticized product;

[0051] S4: Sodium acetate, sodium formate, sodium acrylate, sodium polyacrylate, cross-linked-polyisobutylene-grafted maleate sodium salt are sequentially added to the masticated material obtained in S3 and mixed for 10 minutes, followed by sericite and vulcanized paste. , diatomite, UV stabilizer, antioxidant, rutile titanium dioxide, light calcium carbonate, talc, continue to mix, extrude and slice;

[0052] S5: Add the kneading sheet obtained in S4 to the mixed solvent obtained in S2, stir until it is completely dissolved, and send it to a three-roller for grinding until it is fine and uniform to obtain a sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com