Preparation method of corrosion-mitigating film on steel surface

A steel surface and anti-corrosion technology, applied in the field of metal anti-corrosion, can solve the problems of unsuitable sustainable development, large environmental pollution, high economic cost, etc., and achieve the effect of excellent anti-oxidation performance, firm adsorption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

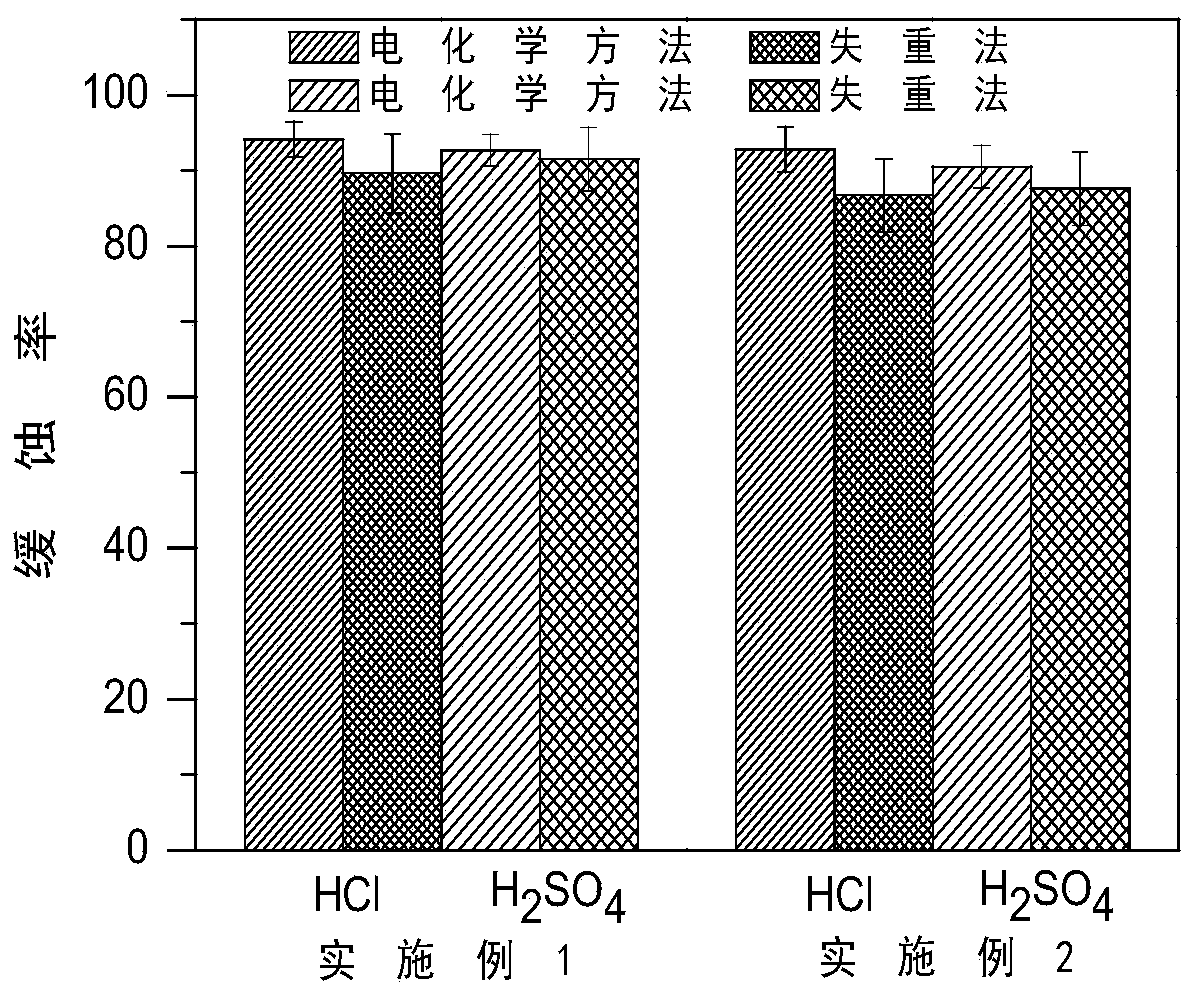

Embodiment 1

[0027] A method for preparing a corrosion-inhibiting film on a steel surface, comprising the following steps:

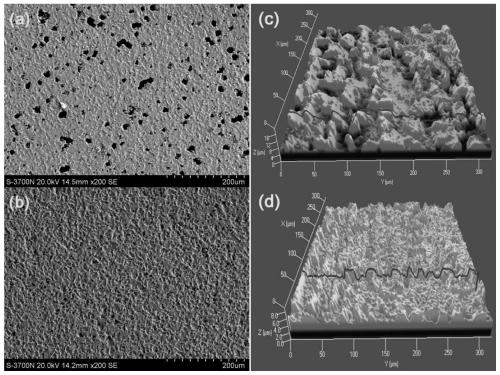

[0028] (1) Rust removal and cleaning of the steel surface: steel samples are treated with 300 # ~2000 # The metallographic sandpaper is polished step by step to obtain a flat surface. The standard is: the flatness measured by the dial indicator is less than 0.02, and then degreased by acetone ultrasonically for 5 minutes, and then rinsed with distilled water;

[0029] (2) Steel surface pretreatment: the cleaned steel sample is firstly placed in 0.1mol / L sulfuric acid solution at 20mA / cm 2 Cathode polarization at constant current density for 10 min, then put in 2mol·L -1 Etch in nitric acid solution for 3 seconds, quickly rinse with distilled water, blow dry with nitrogen, and place in a nitrogen drying box for use;

[0030] (3) Preparation of plant extract: collect the whole plant of Pteris fern, crush it to more than 300 meshes, and get the plant powder sample, m...

Embodiment 2

[0034] A method for preparing a corrosion-inhibiting film on a steel surface, comprising the following steps:

[0035] (1) Rust removal and cleaning of the steel surface: steel samples are treated with 300 # ~2000 # The metallographic sandpaper is polished step by step to obtain a flat surface. The standard is: the flatness measured by the dial indicator is less than 0.02, and then degreased by acetone ultrasonically for 5 minutes, and then rinsed with distilled water;

[0036] (2) Steel surface pretreatment: put the cleaned steel sample into 2mol L -1 Etched in nitric acid solution for 5 seconds, quickly rinsed with distilled water, dried with nitrogen, and placed in a nitrogen drying box for use;

[0037] (3) Preparation of plant extract: collect the whole plant of Pteris fern, crush it to more than 300 meshes, and get the plant powder sample, mix the powder sample and water according to the ratio of 10g:100mL according to the mass volume ratio, and then mix it at 25-30 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com