Method of manufacturing wolfram carbine/platinum compound catalyze material for fuel batter with proton exchange film

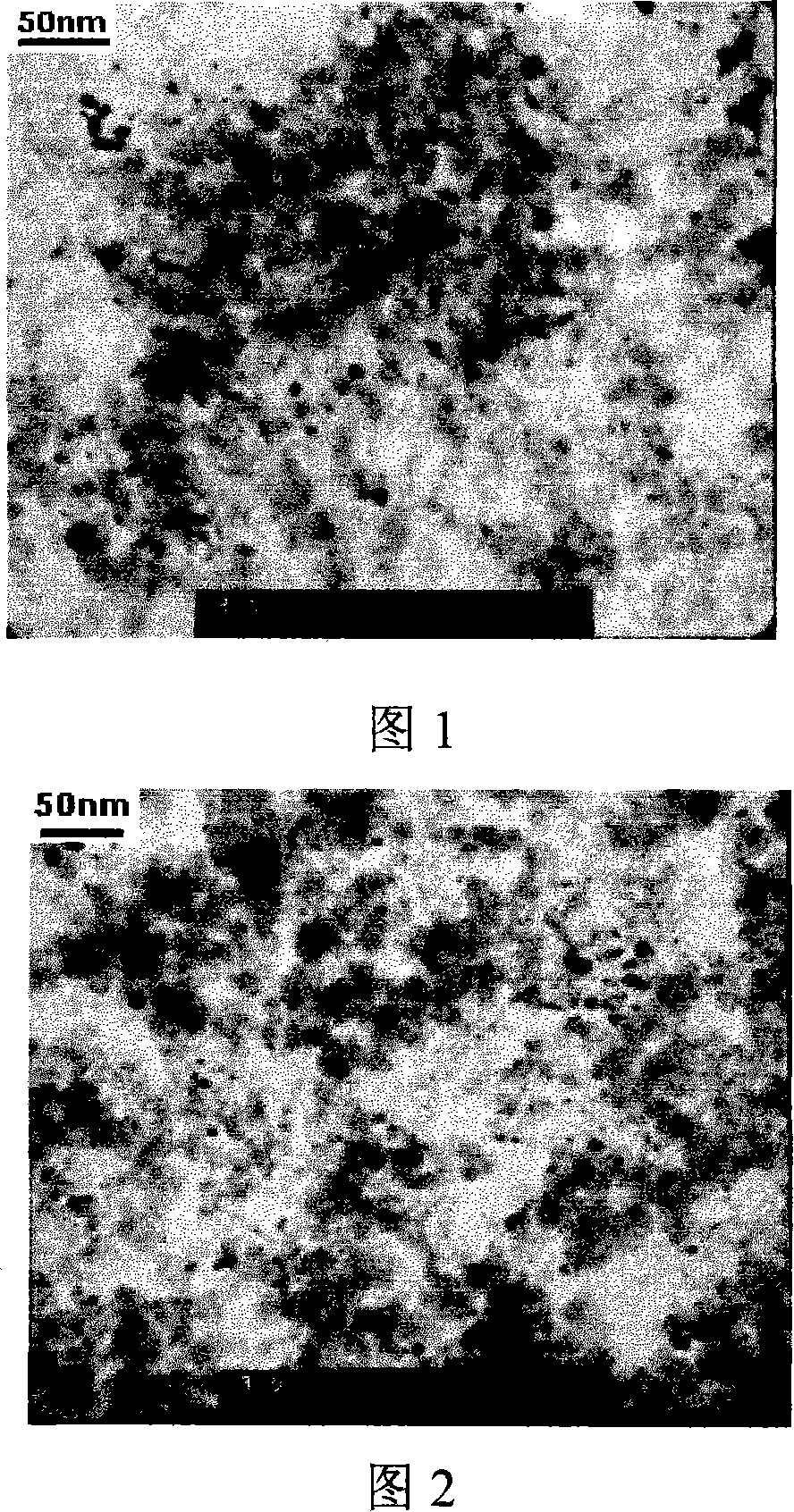

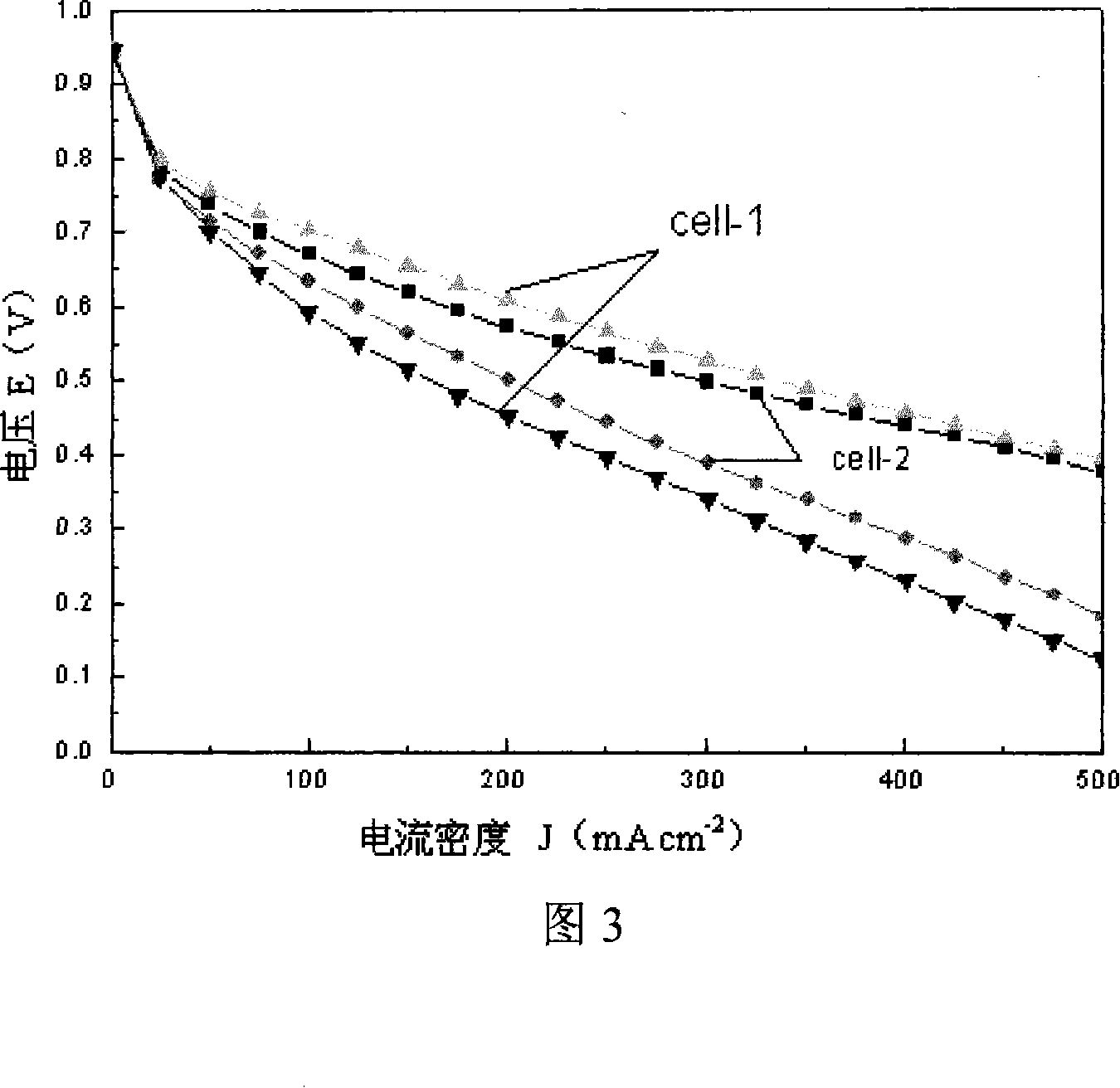

A proton exchange membrane, fuel cell technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of metal particle loss, battery performance loss, etc. Achieve the effect of uniform distribution, simple preparation process and excellent antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step (1), weigh 1g Vulcan XC-72 carbon powder, put in 32% HNO 3 solution, heated to reflux for 1 hour, filtered, washed with deionized water until pH = 6, and dried at a constant temperature of 110°C;

[0022] Step (2), place the Vulcan XC-72 carbon powder processed in step (1) in a three-necked flask, add isopropanol and water, then add H 2 WO 4 The solution, the molar ratio of carbon and tungsten is 1:1, mix well in the ultrasonic wave, add hydrogen peroxide and ammonia water to adjust the pH=6, and let it stand for 5 hours;

[0023] Step (3), in N 2 Add excess NaBH dropwise under the conditions of protection and ultrasonic stirring 4 Solution, carry out reduction reaction; after the reaction is completed, carry out suction filtration, washing, and vacuum drying at 80°C for 4 hours;

[0024] Step (4) product is placed in tube furnace, under N 2 with H 2 Calcination is carried out under a mixed atmosphere, calcination at 800°C for 2 hours, and calcination at 1150...

Embodiment 2

[0029] Step (1), weigh 1g Vulcan XC-72 carbon powder, put in 32% HNO 3 solution, heated to reflux for 1 hour, filtered, washed with deionized water to pH = 6.5, and dried at a constant temperature of 110°C;

[0030] Step (2), place the Vulcan XC-72 carbon powder processed in step (1) in a three-necked flask, add isopropanol and water, then add H 2 WO 4 The solution, the molar ratio of carbon and tungsten is 1:1, fully mixed in the ultrasonic wave, adding hydrogen peroxide and ammonia water to adjust the pH = 6.5, and standing for 5 hours;

[0031] Step (3), in N 2 Add excess NaBH dropwise under the conditions of protection and ultrasonic stirring 4 Solution, carry out reduction reaction; after the reaction is completed, carry out suction filtration, washing, and vacuum drying at 80°C for 4 hours;

[0032] Step (4) product is placed in tube furnace, under N 2 with H 2 Calcination is carried out under a mixed atmosphere, calcination at 800°C for 2.5 hours, and calcination ...

Embodiment 3

[0037] Step (1), weigh 1g Vulcan XC-72 carbon powder, put in 32% HNO 3 solution, heated to reflux for 1 hour, filtered, washed with deionized water until pH = 7, and dried at a constant temperature of 110°C;

[0038] Step (2), place the Vulcan XC-72 carbon powder processed in step (1) in a three-necked flask, add isopropanol and water, then add H 2 WO 4 The solution, the molar ratio of carbon and tungsten is 1:1, mix well in ultrasonic wave, add hydrogen peroxide and ammonia water to adjust pH = 7, and let stand for 6 hours;

[0039] Step (3), in N 2 Add excess NaBH dropwise under the conditions of protection and ultrasonic stirring 4 Solution, carry out reduction reaction; after the reaction is completed, carry out suction filtration, washing, and vacuum drying at 80°C for 4 hours;

[0040] Step (4) product is placed in tube furnace, under N 2 with H 2 Carry out calcination under mixed atmosphere, calcine at 800°C for 3 hours, and calcine at 1150°C for 5 hours to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com