Separated disinfection tank structure based on gastroenterology department endoscope

A gastroenterology, disinfection tank technology, applied in the field of medical devices, can solve the problems of low disinfection efficiency, troublesome disinfection operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

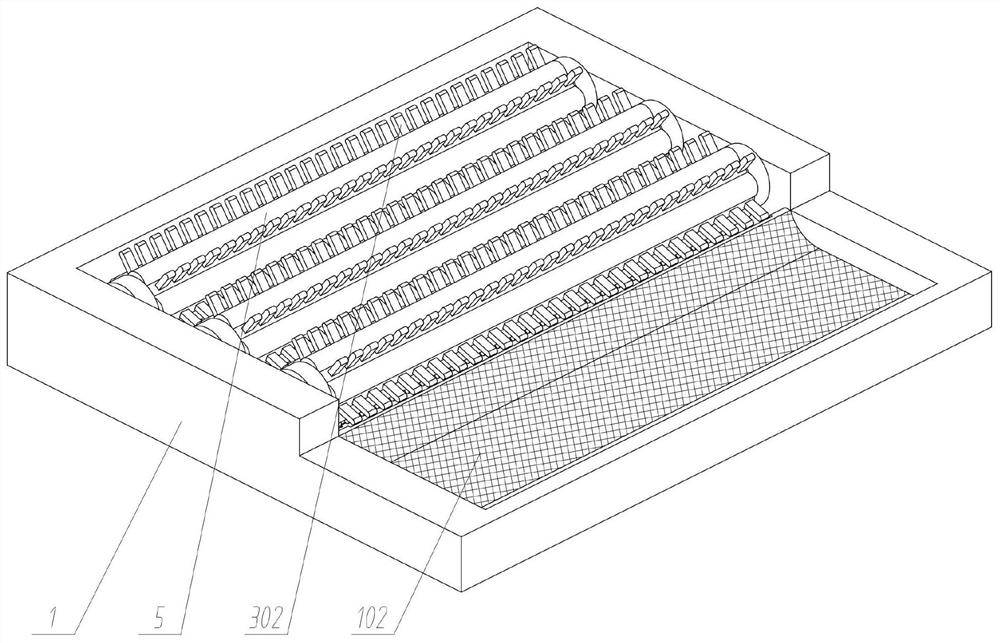

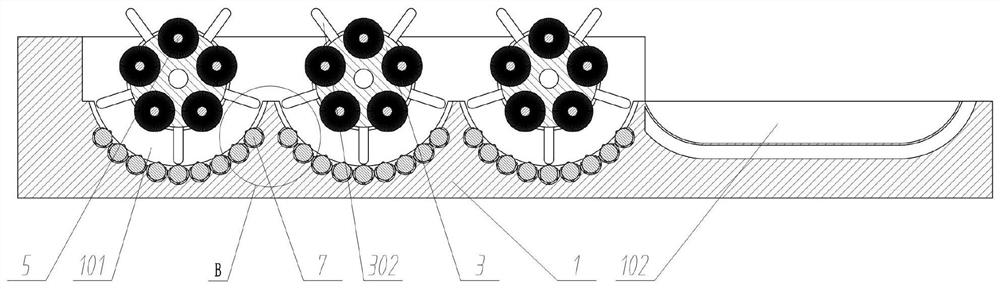

[0053] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a separated disinfection tank structure based on gastroenterology endoscope, including a disinfection tank main body 1;

[0054] The circulation driving part 2, the circulation driving part 2 is fixedly connected to the rear part of the disinfection tank main body 1;

[0055] Circulation mechanism, the circulation mechanism is arranged on the inner side of the upper part of the disinfection tank main body 1;

[0056] The cleaning driver 4 is fixedly connected to the rear of the disinfection tank main body 1;

[0057] Cleaning mechanism, the cleaning mechanism is arranged on the upper part of the disinfection tank main body 1;

[0058] Rotary drive 6, the rotary drive 6 is fixedly connected to the rear of the disinfection tank main body 1;

[0059] The rotation mechanism is arranged on the inner side of the upper part of the disinfection tank main body 1 .

[0060] Further, the disinfection ta...

Embodiment 2

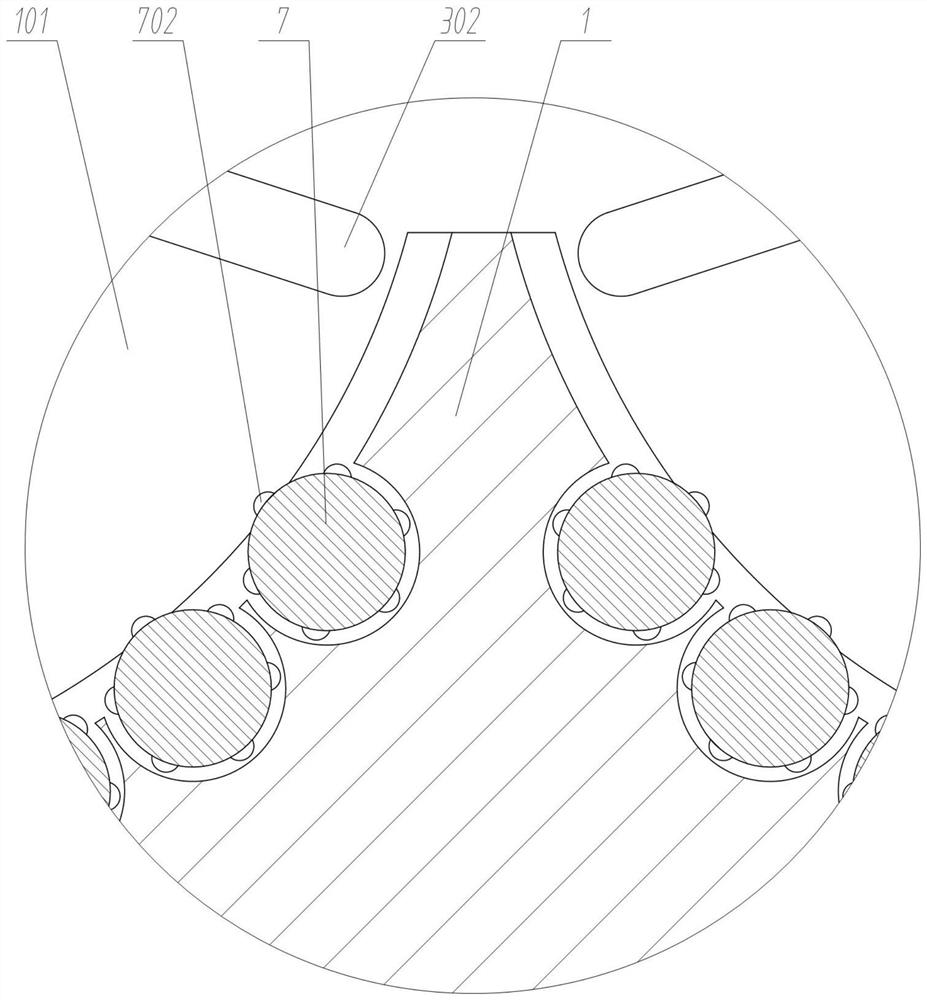

[0086] Another embodiment provided by the present invention: a separated disinfection tank structure based on gastroenterology endoscope, including a disinfection tank main body 1, a cleaning and disinfection tank 101, a collection and storage tank 102, a circulation drive part 2, a circulation active transmission part 201, Circulation operation part 3, circulation co-movement transmission part 301, circulation toggle part 302, cleaning drive part 4, cleaning part 5, cleaning driven gear 501, rotation drive part 6, rotation operation part 7, rotation co-movement transmission part 701, Rotate the friction point 702, clean the intermediate transmission part 8, clean the co-moving transmission part 801, and clean the driving gear 802;

[0087] The difference between the second embodiment and the first embodiment is that the cleaning synchronous transmission part 801 is a transmission sprocket, and the circulation active transmission part 201 and the circulation co-operation transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com