Rotatable multi-degree-of-freedom motion platform

A motion platform and degree of freedom technology, applied in the field of motion platforms, can solve problems such as short life, high mechanical noise, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

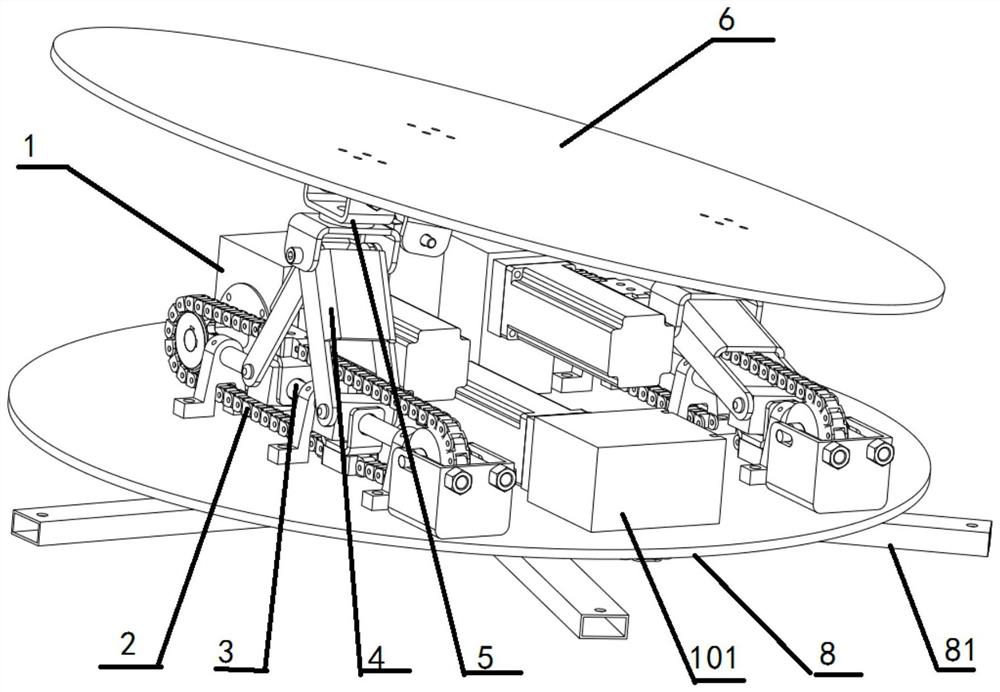

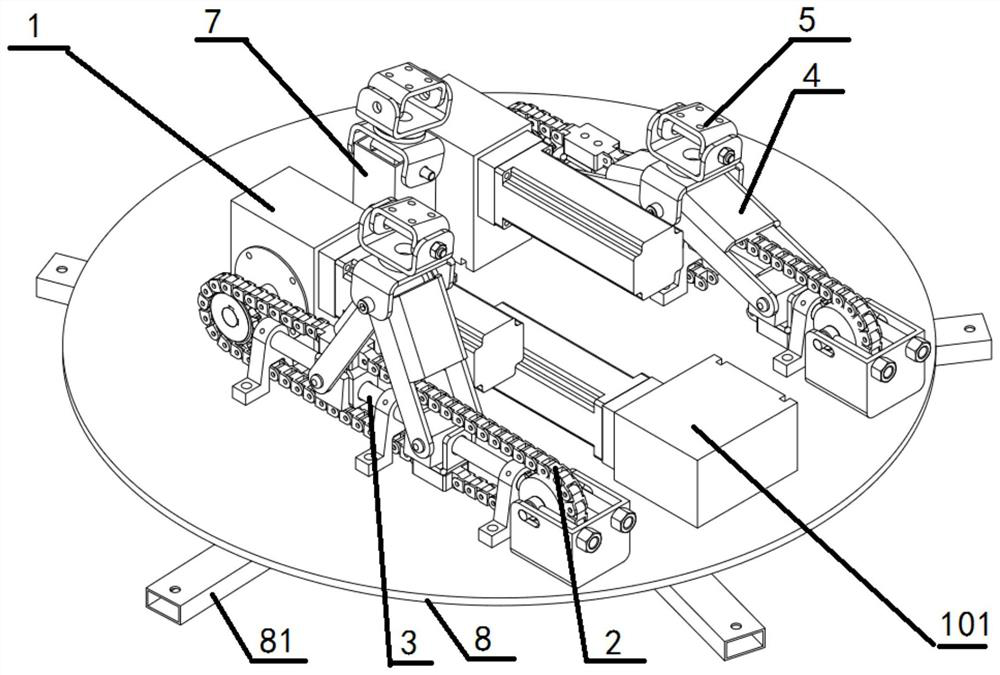

[0059] A rotatable multi-degree-of-freedom motion platform, such as figure 1 As shown, it includes a lifting support unit and an installation platform 6 . Such as figure 2 , image 3 As shown, the lifting support unit includes two lifting units and one supporting unit, and the height of the supporting unit is the middle value between the highest position and the lowest position of the lifting unit. Two lifting units and one supporting unit form three-point support for the installation platform 6, improving the stability of the entire motion platform.

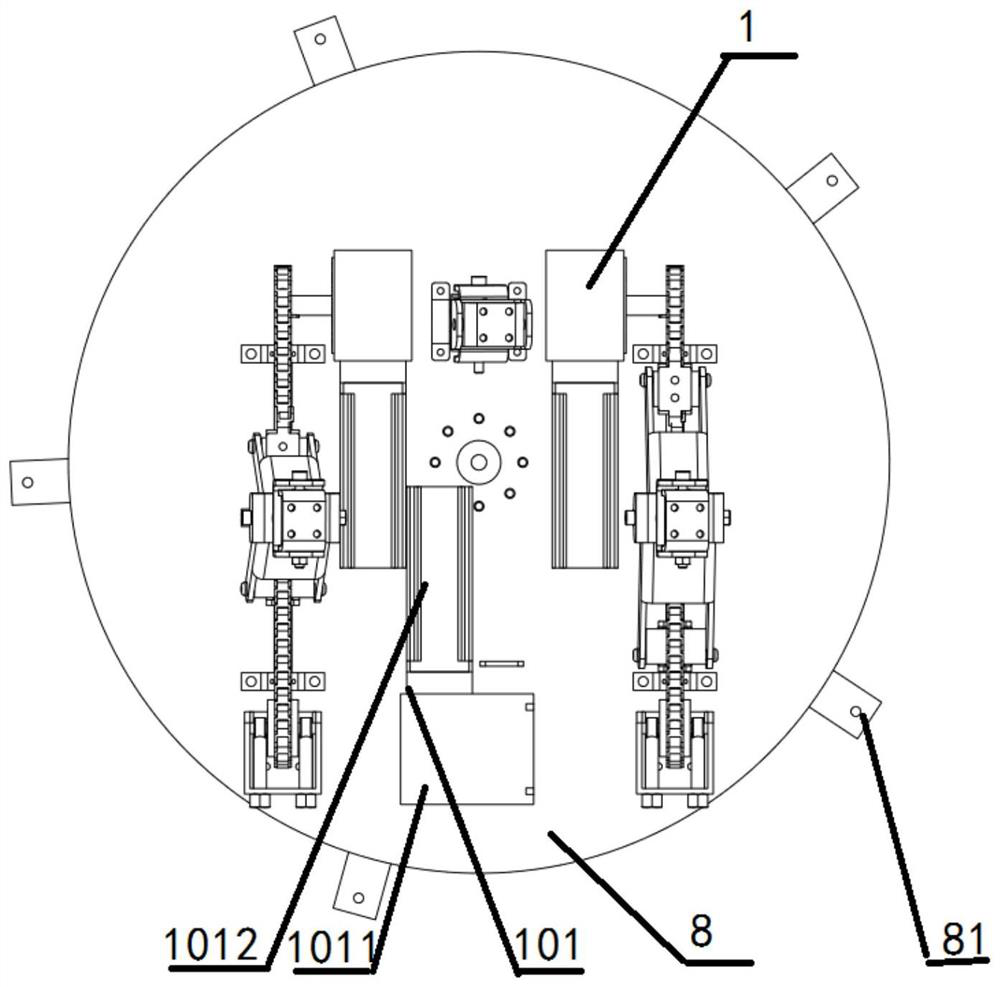

[0060] The lifting unit is used to adjust the level of the entire motion platform. Such as Figure 4 to Figure 6 As shown, the lifting unit includes a first motor drive assembly 1 , a chain transmission assembly 2 , a sliding assembly 3 , a lifting assembly 4 and a universal joint 5 .

[0061] The first motor drive assembly 1 includes a first drive motor 11 and a first reducer 12 , the first drive motor 11 provides power f...

Embodiment 2

[0086] A rotatable multi-degree-of-freedom motion platform, such as figure 1 As shown, it includes a lifting support unit and an installation platform 6 . Such as Figure 9 , Figure 10 As shown, the difference from Embodiment 1 is that the lifting support unit only includes three lifting units, and the three lifting units are evenly distributed along the circumferential direction.

[0087] The lifting unit in embodiment 2 is exactly the same as embodiment 1.

[0088] The base in embodiment 2 is exactly the same as embodiment 1.

[0089] The movement process of the single lifting unit and the rotating unit 10 in the second embodiment is the same as that in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com