Safety type hoisting operation room with folding top cover for truck with loading crane

A technology of folding top cover and truck-mounted lifting is used in transportation and packaging, vehicles with cranes, load hanging components, etc. The effect of environment, protection of personal safety, and avoidance of fall hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

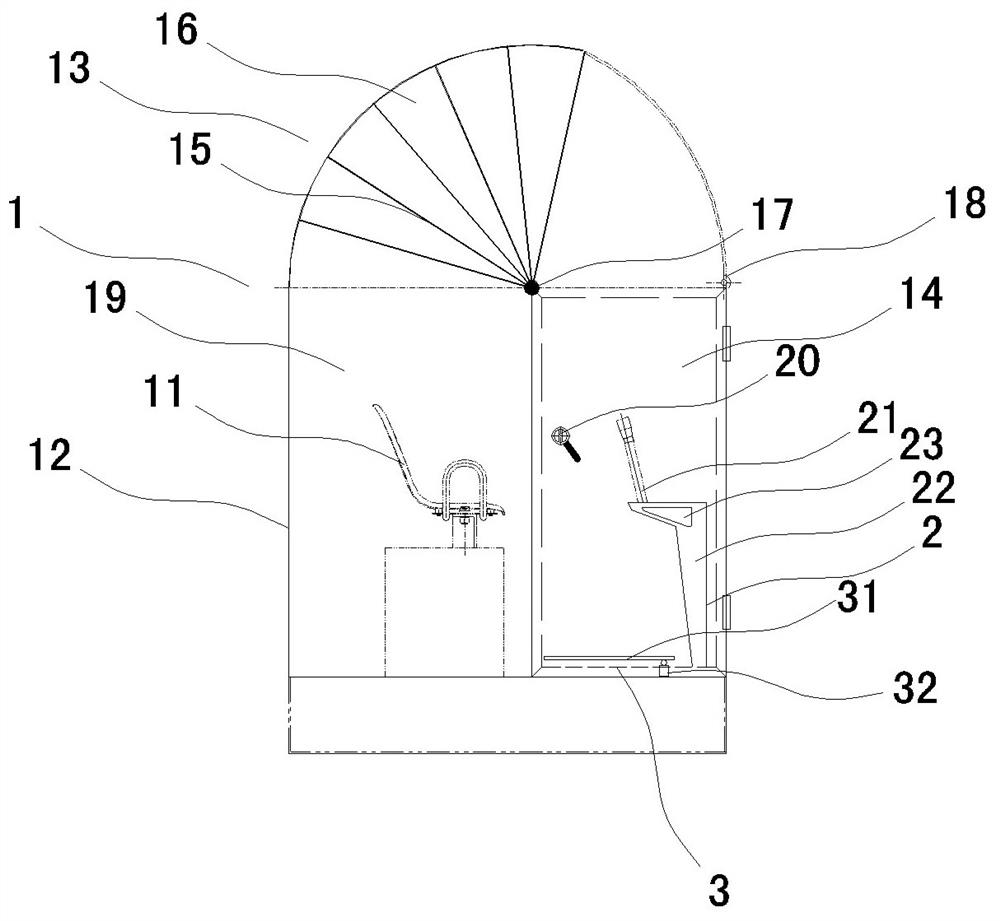

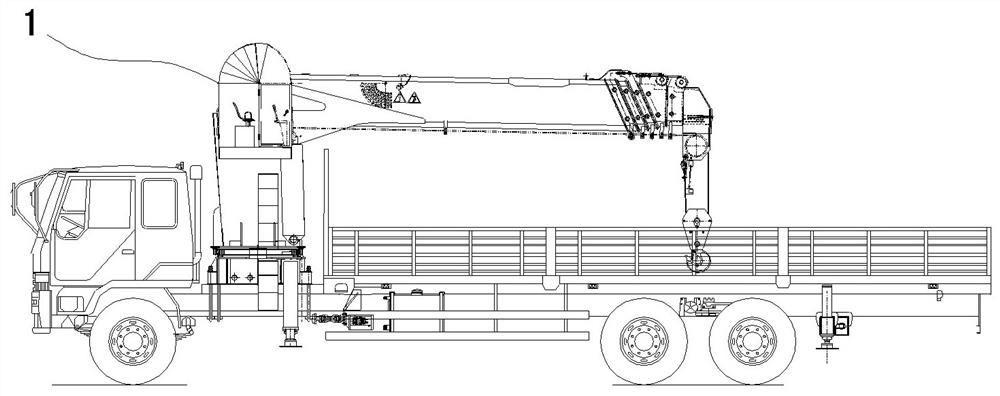

[0010] Embodiment one, such as figure 1 As shown, it includes a lifting operation room 1 and a lifting operation device 2. An operating seat 11 is provided at the rear of the lifting operation room 1, and the joystick 21 of the lifting operating device 2 is located in front of the operating seat 11. Installed in the lifting operation room 1, the lifting operation room 1 is composed of an upwardly open box body 12 and a folding top cover 13 located above the box body 12, and one side of the left and right sides of the box body 12 is provided with a The operating room door 14 on the 12, the folding top cover 13 is made of several door-shaped skeletons 15 and soft top cover curtains 16, and the two ends of each door-shaped skeleton 15 are hinged on the left and right sides of the upper opening of the car body 12 through a support shaft 17 respectively. The middle position of side, the back of soft top cover curtain 16 is installed on the top position of car body 12 rear half sect...

Embodiment 2

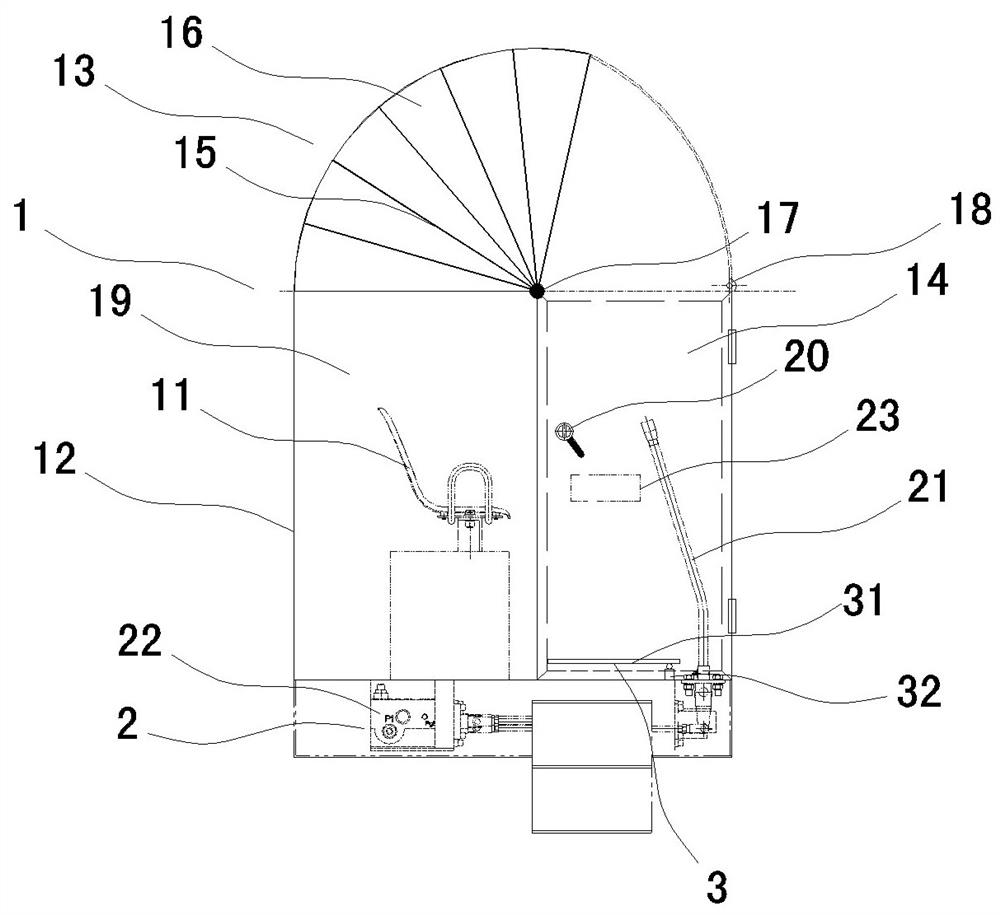

[0019] Embodiment two, such as figure 2 As shown, the difference from Embodiment 1 is that the hydraulic distributor 22 of the lifting operation device 2 is located in the compartment 12 below the operating seat 11, and the electrical control box 23 of the lifting operation device 2 is located in the operating room door 14. The opposite side of is installed on the box body 12 side walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com