Self-expansion type efficient packer

A self-expanding, packer technology, used in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problems of poor sealing effect of packers and different expansion rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

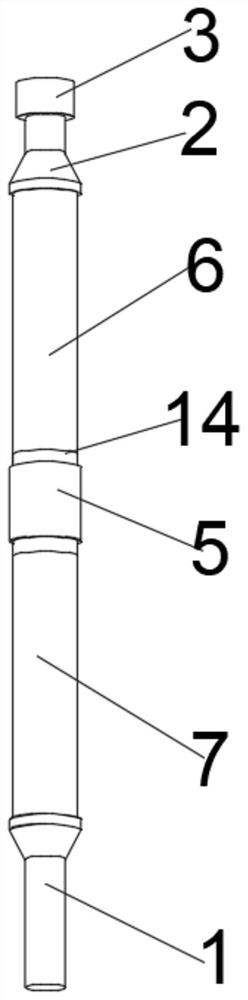

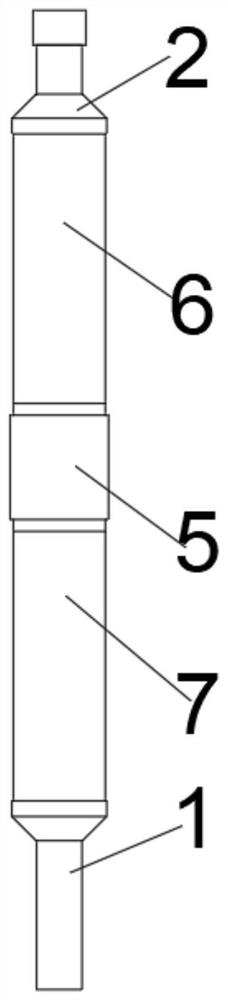

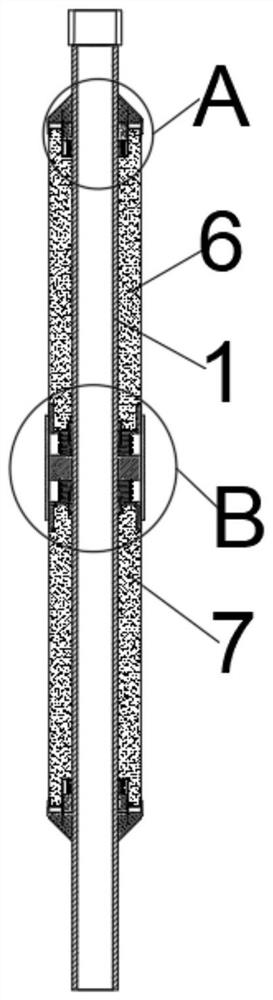

[0031] Such as Figure 1-5 As shown, the embodiment of the present invention provides a self-expanding high-efficiency packer, including a tubing body 1, and the upper and lower ends of the tubing body 1 are fixedly sleeved with a stop ring 2, and the stop ring 2 is set as a circular platform shape, and the outer side of the bottom end is provided with a rib, which is used to wrap the top end of the expansion rubber tube. The top end of the oil pipe body 1 is fixedly connected with a coupling 3, and the outer middle end of the oil pipe body 1 is fixed with a middle stopper. Sleeve 4, the middle limit sleeve 4 is fixedly welded with the oil pipe body 1, and the outer wall of the oil pipe body 1 between the middle limit sleeves 4 of the two limit rings 2 is provided with an upper expansion rubber cylinder 6 and a lower expansion sleeve. The rubber cylinder 7, the upper expansion rubber cylinder 6 and the lower expansion rubber cylinder 7 have the same specifications, and are mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com